EAM_Dynamo_BonnyPasianotMalerba_2009_FeNi__MO_267721408934_005

EAM_Dynamo_BonnyPasianotMalerba_2009_FeNi__MO_267721408934_005

| Title

A single sentence description.

|

EAM potential (LAMMPS cubic hermite tabulation) for the FeNi system developed by Bonny, Pasianot and Malerba (2009) v005 |

|---|---|

| Description

A short description of the Model describing its key features including for example: type of model (pair potential, 3-body potential, EAM, etc.), modeled species (Ac, Ag, ..., Zr), intended purpose, origin, and so on.

|

EAM potential to describe FeNi in the complete concentration range. The main focus was put on the description of experimentally observed intermetallic phases and point defect properties in a dilute Fe-rich matrix. The Fe and Ni potentials were taken from [Mendelev et al., Philos. Mag. 83 (2003) 3977] and [Voter and Chen, Mater. Res. Soc. Symp. Proc. 82 (1987) 175], respectively. |

| Species

The supported atomic species.

| Fe, Ni |

| Disclaimer

A statement of applicability provided by the contributor, informing users of the intended use of this KIM Item.

|

The potential was not stiffened to ZBL. The Fe potential is only suitable to describe alpha-Fe. |

| Content Origin | http://www.ctcms.nist.gov/potentials/Fe.html |

| Contributor |

Giovanni Bonny |

| Maintainer |

Giovanni Bonny |

| Developer |

Giovanni Bonny Roberto C Pasianot L. Malerba |

| Published on KIM | 2018 |

| How to Cite |

This Model originally published in [1] is archived in OpenKIM [2-5]. [1] Bonny G, Pasianot RC, Malerba L. Fe–Ni many-body potential for metallurgical applications. Modelling and Simulation in Materials Science and Engineering. 2009;17(2):025010. doi:10.1088/0965-0393/17/2/025010 — (Primary Source) A primary source is a reference directly related to the item documenting its development, as opposed to other sources that are provided as background information. [2] Bonny G, Pasianot RC, Malerba L. EAM potential (LAMMPS cubic hermite tabulation) for the FeNi system developed by Bonny, Pasianot and Malerba (2009) v005. OpenKIM; 2018. doi:10.25950/e54b898a [3] Foiles SM, Baskes MI, Daw MS, Plimpton SJ. EAM Model Driver for tabulated potentials with cubic Hermite spline interpolation as used in LAMMPS v005. OpenKIM; 2018. doi:10.25950/68defa36 [4] Tadmor EB, Elliott RS, Sethna JP, Miller RE, Becker CA. The potential of atomistic simulations and the Knowledgebase of Interatomic Models. JOM. 2011;63(7):17. doi:10.1007/s11837-011-0102-6 [5] Elliott RS, Tadmor EB. Knowledgebase of Interatomic Models (KIM) Application Programming Interface (API). OpenKIM; 2011. doi:10.25950/ff8f563a Click here to download the above citation in BibTeX format. |

| Citations

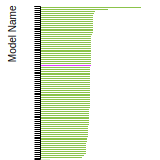

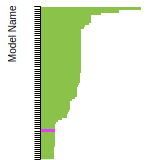

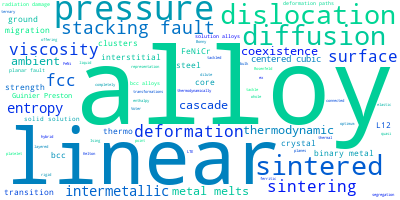

This panel presents information regarding the papers that have cited the interatomic potential (IP) whose page you are on. The OpenKIM machine learning based Deep Citation framework is used to determine whether the citing article actually used the IP in computations (denoted by "USED") or only provides it as a background citation (denoted by "NOT USED"). For more details on Deep Citation and how to work with this panel, click the documentation link at the top of the panel. The word cloud to the right is generated from the abstracts of IP principle source(s) (given below in "How to Cite") and the citing articles that were determined to have used the IP in order to provide users with a quick sense of the types of physical phenomena to which this IP is applied. The bar chart shows the number of articles that cited the IP per year. Each bar is divided into green (articles that USED the IP) and blue (articles that did NOT USE the IP). Users are encouraged to correct Deep Citation errors in determination by clicking the speech icon next to a citing article and providing updated information. This will be integrated into the next Deep Citation learning cycle, which occurs on a regular basis. OpenKIM acknowledges the support of the Allen Institute for AI through the Semantic Scholar project for providing citation information and full text of articles when available, which are used to train the Deep Citation ML algorithm. |

This panel provides information on past usage of this interatomic potential (IP) powered by the OpenKIM Deep Citation framework. The word cloud indicates typical applications of the potential. The bar chart shows citations per year of this IP (bars are divided into articles that used the IP (green) and those that did not (blue)). The complete list of articles that cited this IP is provided below along with the Deep Citation determination on usage. See the Deep Citation documentation for more information.

113 Citations (65 used)

Help us to determine which of the papers that cite this potential actually used it to perform calculations. If you know, click the .

USED (definite) V. Turlo and T. Rupert, “Discovery of a Wide Variety of Linear Complexions in Face Centered Cubic Alloys,” MatSciRN: Other Mechanical Properties & Deformation of Materials (Topic). 2019. link Times cited: 1 Abstract: Linear complexions are defect states that have been recently… read more USED (definite) J. Zhang et al., “A Multi-Scale Multi-Physics Modeling Framework of Laser Powder Bed Fusion Additive Manufacturing Process.” 2018. link Times cited: 22 USED (high confidence) B. Waters, D. S. Karls, I. Nikiforov, R. Elliott, E. Tadmor, and B. Runnels, “Automated determination of grain boundary energy and potential-dependence using the OpenKIM framework,” Computational Materials Science. 2022. link Times cited: 5 USED (high confidence) R. Khusnutdinoff, R. Khairullina, A. Beltyukov, V. Lad’yanov, and A. Mokshin, “Viscous properties of nickel-containing binary metal melts,” Journal of Physics: Condensed Matter. 2020. link Times cited: 0 Abstract: The paper presents the results of molecular dynamics study o… read more USED (high confidence) J. Sublet et al., “Neutron-induced damage simulations: Beyond defect production cross-section, displacement per atom and iron-based metrics,” The European Physical Journal Plus. 2019. link Times cited: 22 USED (high confidence) A. Hasanzadeh, A. Hamedani, G. Alahyarizadeh, A. Minuchehr, and M. Aghaei, “The role of chromium and nickel on the thermal and mechanical properties of FeNiCr austenitic stainless steels under high pressure and temperature: a molecular dynamics study,” Molecular Simulation. 2019. link Times cited: 8 Abstract: ABSTRACT The effect of Cr and Ni content on thermo-mechanica… read more USED (high confidence) V. Turlo and T. Rupert, “Linear Complexions: Metastable Phase Formation and Coexistence at Dislocations.,” Physical review letters. 2018. link Times cited: 15 Abstract: The unique three-phase coexistence of metastable B2-FeNi wit… read more USED (high confidence) V. Turlo and T. Rupert, “Dislocation-assisted linear complexion formation driven by segregation,” Scripta Materialia. 2018. link Times cited: 12 USED (high confidence) Y. Zhang, S. Zhao, W. J. Weber, K. Nordlund, F. Granberg, and F. Djurabekova, “Atomic-level heterogeneity and defect dynamics in concentrated solid-solution alloys,” Current Opinion in Solid State & Materials Science. 2017. link Times cited: 142 USED (high confidence) S. Zhao, Y. Osetsky, and Y. Zhang, “Preferential diffusion in concentrated solid solution alloys: NiFe, NiCo and NiCoCr ☆,” Acta Materialia. 2017. link Times cited: 120 USED (high confidence) S. Zhao, G. M. Stocks, and Y. Zhang, “Defect energetics of concentrated solid-solution alloys from ab initio calculations: Ni0.5Co0.5, Ni0.5Fe0.5, Ni0.8Fe0.2 and Ni0.8Cr0.2.,” Physical chemistry chemical physics : PCCP. 2016. link Times cited: 81 Abstract: It has been shown that concentrated solid solution alloys po… read more USED (high confidence) Y. Zhang and J. Zhang, “Sintering phenomena and mechanical strength of nickel based materials in direct metal laser sintering process—a molecular dynamics study,” Journal of Materials Research. 2016. link Times cited: 35 Abstract: This paper presents an atomistic scale model on sintering of… read more USED (high confidence) L. Béland, G. Samolyuk, and R. Stoller, “Differences in the accumulation of ion-beam damage in Ni and NiFe explained by atomistic simulations,” Journal of Alloys and Compounds. 2016. link Times cited: 30 USED (high confidence) K. Vörtler, N. Juslin, N. Juslin, G. Bonny, L. Malerba, and K. Nordlund, “The effect of prolonged irradiation on defect production and ordering in Fe–Cr and Fe–Ni alloys,” Journal of Physics: Condensed Matter. 2011. link Times cited: 54 Abstract: The understanding of the primary radiation damage in Fe-base… read more USED (high confidence) C. Becker, F. Tavazza, and L. Levine, “Implications of the choice of interatomic potential on calculated planar faults and surface properties in nickel,” Philosophical Magazine. 2011. link Times cited: 15 Abstract: With the increasing use of molecular simulation to understan… read more USED (high confidence) M. Byshkin, B. Zhu, and M. Hou, “The effect of encapsulation in carbon nanotubes on properties of Fe–Ni nanoalloys with cubic and helical structures,” Journal of Materials Science. 2012. link Times cited: 1 USED (low confidence) T. Ye et al., “Molecular dynamics simulation of tensile deformation behavior of single-crystal Fe–Cr–Al before and after irradiation,” Journal of Materials Research. 2022. link Times cited: 1 Abstract: Fe–Cr–Al alloy is one of the candidate materials for reactor… read more USED (low confidence) R. Khusnutdinoff, R. R. Khairullina, A. L. Bel’tyukov, V. Lad’yanov, and A. Mokshin, “Viscoelastic and Quasi-Solid Properties of Ni-Containing Binary Metal Melts,” High Temperature. 2022. link Times cited: 0 USED (low confidence) V. Drozd, M. Asadikiya, S. Yang, and Y. Zhong, “Energy and Mechanical Properties Predictions in Fe-Ni Binary System by ab initio Calculations,” Materials Today Communications. 2022. link Times cited: 3 USED (low confidence) X. Li, Y. Shi, T.-Y. Chen, S. Wang, and K. Fan, “Study on Sintering Mechanism and Mechanical Properties of Fe–Ni Elastocaloric Refrigeration Alloy through Molecular Dynamics Simulation,” Materials Today Communications. 2022. link Times cited: 4 USED (low confidence) Y. Ma et al., “Atomic diffusion behavior near the bond interface during the explosive welding process based on molecular dynamics simulations,” Materials Today Communications. 2022. link Times cited: 6 USED (low confidence) Y.-chao Liang et al., “Influence of cluster correlation on nanoclusters in Fe-Ni amorphous alloys,” Journal of Alloys and Compounds. 2022. link Times cited: 10 USED (low confidence) N. Ren, L. Hu, B. Wang, K. Song, and P. Guan, “Structural topological signature of high-temperature non-Arrhenius crossover in metallic glass-forming liquids,” Scripta Materialia. 2021. link Times cited: 5 USED (low confidence) F. Baras, Q. Bizot, A. Fourmont, S. L. Gallet, and O. Politano, “Mechanical activation of metallic powders and reactivity of activated nanocomposites: a molecular dynamics approach,” Applied Physics A. 2021. link Times cited: 1 USED (low confidence) S. Zhao, “Influence of temperature and alloying elements on the threshold displacement energies in concentrated Ni–Fe–Cr alloys*,” Chinese Physics B. 2021. link Times cited: 3 USED (low confidence) A. Maulana, A. Arkundato, Sutisna, and H. Trilaksana, “Mechanical properties of Fe, Ni and Fe-Ni alloy: Strength and stiffness of materials using lammps molecular dynamics simulation.” 2020. link Times cited: 2 Abstract: The mechanical properties of pure metals and alloy Fe-Ni wit… read more USED (low confidence) V. Turlo and T. Rupert, “Interdependent Linear Complexion Structure and Dislocation Mechanics in Fe-Ni,” Crystals. 2020. link Times cited: 4 Abstract: Using large-scale atomistic simulations, dislocation mechani… read more USED (low confidence) G. Zhang, Y. Kang, M. Wang, H. Xu, and H.-Z. Jia, “Atomic diffusion behavior and diffusion mechanism in Fe–Cu bimetal casting process studied by molecular dynamics simulation and experiment,” Materials Research Express. 2020. link Times cited: 9 Abstract: A molecular dynamics (MD) method with an embedded atomic met… read more USED (low confidence) Q. Jiang, H. Liu, J. Li, D. Yang, Y. Zhang, and W. Yang, “Atomic-level understanding of crystallization in the selective laser melting of Fe50Ni50 amorphous alloy,” Additive manufacturing. 2020. link Times cited: 21 USED (low confidence) N. Anento and A. Serra, “Interaction of a mobile 1 1 2 grain boundary with radiation induced defects in α-Fe: Transformation of defects and impact on the shear-coupled grain boundary migration,” Computational Materials Science. 2020. link Times cited: 14 USED (low confidence) B. Yu et al., “MD simulation on crystallization mechanisms of rapidly supercooled Fe-Ni alloys,” Journal of Crystal Growth. 2020. link Times cited: 10 USED (low confidence) H. Luu and N. Gunkelmann, “Pressure-induced phase transformations in Fe-C: Molecular dynamics approach,” Computational Materials Science. 2019. link Times cited: 24 USED (low confidence) L. Belkacemi, E. Meslin, B. Décamps, B. Radiguet, and J. Henry, “Radiation-induced bcc-fcc phase transformation in a Fe 3%Ni alloy,” Acta Materialia. 2018. link Times cited: 28 USED (low confidence) A. Mangla, G. Deo, and P. A. Apte, “NiFe local ordering in segregated Ni3Fe alloys: A simulation study using angular dependent potential,” Computational Materials Science. 2018. link Times cited: 8 USED (low confidence) A. Bakaev, D. Terentyev, and E. Zhurkin, “Effect of Segregation of Ni and Cr at Dislocation Loops on Their Interaction with Gliding Dislocations in Irradiated Fe−Ni−Cr BCC Alloys,” Journal of Surface Investigation: X-ray, Synchrotron and Neutron Techniques. 2018. link Times cited: 1 USED (low confidence) Y. Dou et al., “Effect of Ni and Mn on the Interaction of an Edge Dislocation with Cu-rich Precipitates in Bcc Fe,” High-Performance Computing Applications in Numerical Simulation and Edge Computing. 2018. link Times cited: 1 USED (low confidence) X. He, S. Wu, L. Jia, D. Wang, Y. Dou, and W. Yang, “Grain Boundary Segregation of Substitutional Solutes/Impurities and Grain Boundary Decohesion in BCC Fe,” Energy Procedia. 2017. link Times cited: 5 USED (low confidence) C.-jun Wu, B.-J. Lee, and X. Su, “Modified embedded-atom interatomic potential for Fe-Ni, Cr-Ni and Fe-Cr-Ni systems,” Calphad-computer Coupling of Phase Diagrams and Thermochemistry. 2017. link Times cited: 60 USED (low confidence) G. Lv and Y. Su, “Molecular dynamics simulation and first principles calculations of radiation-induced Cu clusters in Fe-3 at.% Cu alloy,” Comput. Phys. Commun. 2017. link Times cited: 5 USED (low confidence) G. Bonny, A. Bakaev, P. Olsson, C. Domain, E. Zhurkin, and M. Posselt, “Interatomic potential to study the formation of NiCr clusters in high Cr ferritic steels,” Journal of Nuclear Materials. 2017. link Times cited: 17 USED (low confidence) N. Lopanitsyna and A. Kuksin, “Nucleation and the spall strength of liquid metals,” Journal of Physics: Conference Series. 2016. link Times cited: 2 Abstract: This article presents calculation of the nucleation rate for… read more USED (low confidence) D. Terentyev, A. Zinovev, and G. Bonny, “Displacement cascades in FeNiMnCu alloys: RVP model alloys,” Journal of Nuclear Materials. 2016. link Times cited: 7 USED (low confidence) L. You, L. Hu, Y. Xie, and S. Zhao, “Influence of Cu precipitation on tensile properties of Fe–Cu–Ni ternary alloy at different temperatures by molecular dynamics simulation,” Computational Materials Science. 2016. link Times cited: 14 USED (low confidence) G. Lv, H. Zhang, X. He, W. Yang, and Y. Su, “Vacancy enhanced formation and phase transition of Cu-rich precipitates in α - iron under neutron irradiation,” AIP Advances. 2016. link Times cited: 2 Abstract: In this paper, we employed both molecular statics and molecu… read more USED (low confidence) K. Xiong, X. Liu, and J. Gu, “Multiscale modeling of nanoindentation-induced instability in FeNi3 crystal,” Computational Materials Science. 2015. link Times cited: 6 USED (low confidence) D. Terentyev, X. He, G. Bonny, A. Bakaev, E. Zhurkin, and L. Malerba, “Hardening due to dislocation loop damage in RPV model alloys: Role of Mn segregation,” Journal of Nuclear Materials. 2015. link Times cited: 36 USED (low confidence) G. Bonny, D. Terentyev, E. Zhurkin, and L. Malerba, “Monte Carlo study of decorated dislocation loops in FeNiMnCu model alloys,” Journal of Nuclear Materials. 2014. link Times cited: 45 USED (low confidence) C.-B. Wang, W. Zhang, C. Ren, P. Huai, and Z. Zhu, “The effect of temperature on primary defect formation in Ni–Fe alloy,” Nuclear Instruments & Methods in Physics Research Section B-beam Interactions With Materials and Atoms. 2014. link Times cited: 16 USED (low confidence) G. Bonny et al., “On the thermal stability of late blooming phases in reactor pressure vessel steels: An atomistic study,” Journal of Nuclear Materials. 2013. link Times cited: 77 USED (low confidence) T. Fang, L. Wang, and Y. Qi, “Structural, Thermodynamics and Dynamics Properties of Fe-Ni Melts with Different EAM Models,” Advanced Materials Research. 2013. link Times cited: 1 Abstract: Molecular dynamics (MD) simulation has been performed to exp… read more USED (low confidence) X. Shu et al., “Fe self-diffusion and Cu and Ni diffusion in bulk and grain boundary of Fe: A molecular dynamics study,” Nuclear Instruments & Methods in Physics Research Section B-beam Interactions With Materials and Atoms. 2013. link Times cited: 10 USED (low confidence) T. Fang, L. Wang, and Y. Qi, “Molecular Dynamics Simulation of Liquid Cu-Ni Alloy Using Embedded Atom Method,” Advanced Materials Research. 2013. link Times cited: 0 Abstract: Molecular dynamics simulation has been performed to explore … read more USED (low confidence) R. Idczak, R. Konieczny, and J. Chojcan, “Thermodynamic properties of Fe–Ni solid solutions studied by 57Fe Mössbauer spectroscopy,” Physica B-condensed Matter. 2012. link Times cited: 5 USED (low confidence) D. Terentyev, L. Malerba, G. Bonny, A. Al-Motasem, and M. Posselt, “Interaction of an edge dislocation with Cu–Ni-vacancy clusters in bcc iron,” Journal of Nuclear Materials. 2011. link Times cited: 24 USED (low confidence) A. Al-Motasem, M. Posselt, and F. Bergner, “Nanoclusters in bcc-Fe containing vacancies, copper and nickel: Structure and energetics,” Journal of Nuclear Materials. 2011. link Times cited: 25 USED (low confidence) R. Anders and F. Haider, “Calculation of phase diagrams and simulation of segregation using Monte Carlo with lattice relaxation,” Journal of Nuclear Materials. 2010. link Times cited: 0 USED (low confidence) L. Sandoval, H. Urbassek, and P. Entel, “Solid-solid phase transitions and phonon softening in an embedded-atom method model for iron,” Physical Review B. 2009. link Times cited: 36 USED (low confidence) N. Castin, L. Malerba, G. Bonny, M. I. Pascuet, and M. Hou, “Modelling radiation-induced phase changes in binary FeCu and ternary FeCuNi alloys using an artificial intelligence-based atomistic kinetic Monte Carlo approach,” Nuclear Instruments & Methods in Physics Research Section B-beam Interactions With Materials and Atoms. 2009. link Times cited: 24 USED (low confidence) Y. Zhang, Y. G. Jung, and J. Zhang, “Molecular dynamics modeling of sintering phenomena and mechanical strength of metal particles.” 2020. link Times cited: 0 USED (low confidence) H. Zheng, B. Li, Y. Tan, G. Li, X. Shu, and P. Peng, “Derivative effect of laser cladding on interface stability of YSZ@Ni coating on GH4169 alloy: An experimental and theoretical study,” Applied Surface Science. 2018. link Times cited: 8 USED (low confidence) S. Paul, Nagahanumaiah, S. Mitra, and D. Roy, “Molecular Dynamics Simulation Study of Neck Growth in Micro-selective Laser Sintering of Copper Nanoparticles.” 2018. link Times cited: 6 USED (low confidence) Y. Zhang, L. Wu, H. El-Mounayri, K. Brand, and J. Zhang, “Molecular Dynamics Study of the Strength of Laser Sintered Iron Nanoparticles,” Procedia Manufacturing. 2015. link Times cited: 28 USED (low confidence) D. Molnár, P. Binkele, A. Mora, R. Mukherjee, B. Nestler, and S. Schmauder, “Molecular Dynamics virtual testing of thermally aged Fe–Cu microstructures obtained from multiscale simulations,” Computational Materials Science. 2014. link Times cited: 9 USED (low confidence) R. Khanna and V. Sahajwalla, “Atomistic Simulations of Properties and Phenomena at High Temperatures.” 2014. link Times cited: 3 USED (low confidence) D. Li, H. Zbib, X. Sun, and M. Khaleel, “Predicting plastic flow and irradiation hardening of iron single crystal with mechanism-based continuum dislocation dynamics,” International Journal of Plasticity. 2014. link Times cited: 107 NOT USED (low confidence) Y. Xu, G. Wang, J. Shen, P. Qian, and Y. Su, “Structural features, thermal stability and catalytic implication of Fe–Ni nanoparticles,” Journal of Solid State Chemistry. 2023. link Times cited: 0 NOT USED (low confidence) A. Mangla, G. Deo, and P. A. Apte, “Cooperative freezing of the L12 ordered domains at the critical cooling temperature of Ni3Fe alloy,” Journal of Statistical Mechanics: Theory and Experiment. 2022. link Times cited: 0 Abstract: It is well known that Ni3Fe transforms from a disordered sol… read more NOT USED (low confidence) W.-Z. L. S.-Z. Yu et al., “Machine‐learning‐based interatomic potentials for advanced manufacturing,” International Journal of Mechanical System Dynamics. 2021. link Times cited: 2 Abstract: This paper summarizes the progress of machine‐learning‐based… read more NOT USED (low confidence) E. Meshkov, I. Novoselov, A. Shapeev, and A. Yanilkin, “Sublattice formation in CoCrFeNi high-entropy alloy,” Intermetallics. 2019. link Times cited: 17 NOT USED (low confidence) V. Turlo and T. Rupert, “Prediction of a wide variety of linear complexions in face centered cubic alloys,” Acta Materialia. 2019. link Times cited: 11 NOT USED (low confidence) N. Ren, B. Shang, P. Guan, and L. Hu, “General structural and dynamic characteristics beneficial to glass-forming ability of Fe-based glass-forming liquids,” Journal of Non-crystalline Solids. 2018. link Times cited: 7 NOT USED (low confidence) L. Béland et al., “Accurate classical short-range forces for the study of collision cascades in Fe-Ni-Cr,” Comput. Phys. Commun. 2017. link Times cited: 34 NOT USED (low confidence) S. M. Rassoulinejad-Mousavi, Y. Mao, and Y. Zhang, “Evaluation of Copper, Aluminum and Nickel Interatomic Potentials on Predicting the Elastic Properties,” arXiv: Computational Physics. 2016. link Times cited: 63 Abstract: Choice of appropriate force field is one of the main concern… read more NOT USED (low confidence) K. Xiong and J. Gu, “Understanding pop-in phenomena in FeNi3 nanoindentation,” Intermetallics. 2015. link Times cited: 19 NOT USED (low confidence) C. P. Chui, W. Liu, Y. Xu, and Y. Zhou, “Molecular Dynamics Simulation of Iron — A Review.” 2015. link Times cited: 3 Abstract: Molecular dynamics (MD) is a technique of atomistic simulati… read more NOT USED (low confidence) Z. Trautt, F. Tavazza, and C. Becker, “Facilitating the selection and creation of accurate interatomic potentials with robust tools and characterization,” Modelling and Simulation in Materials Science and Engineering. 2015. link Times cited: 14 Abstract: The Materials Genome Initiative seeks to significantly decre… read more NOT USED (low confidence) Y. Osetsky, N. Anento, A. Serra, and D. Terentyev, “The role of nickel in radiation damage of ferritic alloys,” Acta Materialia. 2015. link Times cited: 18 NOT USED (low confidence) W. Cui, C. Peng, L. Wang, Y. Qi, and T. Fang, “Structure and dynamics of undercooled FeNi,” Physics and Chemistry of Liquids. 2014. link Times cited: 2 Abstract: Molecular dynamics simulation has been performed to explore … read more NOT USED (low confidence) N. Gunkelmann, H. Ledbetter, and H. Urbassek, “Experimental and atomistic study of the elastic properties of α′ Fe–C martensite,” Acta Materialia. 2012. link Times cited: 38 NOT USED (low confidence) L. Malerba et al., “Comparison of empirical interatomic potentials for iron applied to radiation damage studies,” Journal of Nuclear Materials. 2010. link Times cited: 210 NOT USED (low confidence) G. Ackland and G. Bonny, “Interatomic Potential Development,” Comprehensive Nuclear Materials. 2020. link Times cited: 4 NOT USED (low confidence) L. Malerba, “Multi-scale modelling of irradiation effects in nuclear power plant materials.” 2010. link Times cited: 3 Abstract: Abstract: This chapter surveys the computer-based multi-scal… read more NOT USED (high confidence) P. Yu, L. Zhang, and L. Du, “Atomic Simulations for Packing Changes of Nano-Sized Cu Clusters Embedded in the Febulk on Heating,” Metals. 2021. link Times cited: 3 Abstract: Understanding of the defect evolution mechanism under irradi… read more NOT USED (high confidence) K. Li and C. Fu, “Ground-state properties and lattice-vibration effects of disordered Fe-Ni systems for phase stability predictions,” Physical Review Materials. 2020. link Times cited: 6 Abstract: By means of density functional theory, we perform a focused … read more NOT USED (high confidence) J.-B. Wang, R. Huang, and Y. Wen, “Thermally activated phase transitions in Fe-Ni core-shell nanoparticles,” Frontiers of Physics. 2019. link Times cited: 0 NOT USED (high confidence) T. M. Whiting, P. Burr, D. King, and M. Wenman, “Understanding the importance of the energetics of Mn, Ni, Cu, Si and vacancy triplet clusters in bcc Fe,” Journal of Applied Physics. 2019. link Times cited: 11 Abstract: Numerous experimental studies have found the presence of (Cu… read more NOT USED (high confidence) S. Zhi-peng, D. Fuzhi, X. Ben, and Z. Wen-zheng, “Three-Dimensional Growth of Coherent Ferrite in Austenite: A Molecular Dynamics Study,” Acta Metallurgica Sinica (english Letters). 2019. link Times cited: 1 NOT USED (high confidence) Z. Sun, F. Z. Dai, B. Xu, and W.-Z. Zhang, “Three-Dimensional Growth of Coherent Ferrite in Austenite: A Molecular Dynamics Study,” Acta Metallurgica Sinica (English Letters). 2019. link Times cited: 5 NOT USED (high confidence) S. Mahmoud and N. Mousseau, “Long-time point defect diffusion in ordered nickel-based binary alloys: How small kinetic differences can lead to completely long-time structural evolution,” Materialia. 2018. link Times cited: 15 NOT USED (high confidence) N. Anento, A. Serra, and Y. Osetsky, “Effect of nickel on point defects diffusion in Fe – Ni alloys,” Acta Materialia. 2017. link Times cited: 30 NOT USED (high confidence) A. Bakaev, A. Bakaev, D. Terentyev, and E. Zhurkin, “Atomistic simulation of the segregation of alloying elements close to radiation-induced defects in irradiated Fe–Cr–Ni BCC alloys,” Journal of Surface Investigation: X-ray, Synchrotron and Neutron Techniques. 2017. link Times cited: 4 NOT USED (high confidence) L. Béland, Y. Osetsky, and R. Stoller, “The effect of alloying nickel with iron on the supersonic ballistic stage of high energy displacement cascades,” Acta Materialia. 2016. link Times cited: 28 NOT USED (high confidence) Y. Osetsky, L. Béland, and R. Stoller, “Specific features of defect and mass transport in concentrated fcc alloys,” Acta Materialia. 2016. link Times cited: 67 NOT USED (high confidence) Y. Zhang et al., “Influence of chemical disorder on energy dissipation and defect evolution in advanced alloys,” Journal of Materials Research. 2016. link Times cited: 103 Abstract: Historically, alloy development with better radiation perfor… read more NOT USED (high confidence) K. Tong, F. Ye, M. Gao, M. Lei, and C. Zhang, “Interatomic potential for Fe–Cr–Ni–N system based on the second nearest-neighbor modified embedded-atom method,” Molecular Simulation. 2016. link Times cited: 7 Abstract: The interatomic potential for Fe–Cr–Ni–N system based on the… read more NOT USED (high confidence) L. Béland et al., “Features of primary damage by high energy displacement cascades in concentrated Ni-based alloys,” Journal of Applied Physics. 2016. link Times cited: 53 Abstract: Alloying of Ni with Fe or Co has been shown to reduce primar… read more NOT USED (high confidence) E. Sak-Saracino and H. Urbassek, “Temperature-induced phase transformation of Fe1-xNix alloys: molecular-dynamics approach,” The European Physical Journal B. 2015. link Times cited: 17 NOT USED (high confidence) A. Ojha, H. Sehitoglu, L. Patriarca, and H. Maier, “Twin nucleation in Fe-based bcc alloys—modeling and experiments,” Modelling and Simulation in Materials Science and Engineering. 2014. link Times cited: 43 Abstract: We develop an analytical expression for twin nucleation stre… read more NOT USED (high confidence) M. Lavrentiev, J. Wróbel, D. Nguyen-Manh, and S. Dudarev, “Magnetic and thermodynamic properties of face-centered cubic Fe-Ni alloys.,” Physical chemistry chemical physics : PCCP. 2014. link Times cited: 48 Abstract: A model lattice ab initio parameterized Heisenberg-Landau ma… read more NOT USED (high confidence) G. Bonny, N. Castin, and D. Terentyev, “Interatomic potential for studying ageing under irradiation in stainless steels: the FeNiCr model alloy,” Modelling and Simulation in Materials Science and Engineering. 2013. link Times cited: 215 Abstract: The degradation of austenitic stainless steels in a radiatio… read more NOT USED (high confidence) E. Barker, D. Li, H. Zbib, and X. Sun, “Gradient Plasticity Model and its Implementation into MARMOT.” 2013. link Times cited: 0 Abstract: The influence of strain gradient on deformation behavior of … read more NOT USED (high confidence) S. G. Mayr and A. Arabi-Hashemi, “Structural defects in Fe–Pd-based ferromagnetic shape memory alloys: tuning transformation properties by ion irradiation and severe plastic deformation,” New Journal of Physics. 2012. link Times cited: 8 Abstract: Fe–Pd-based ferromagnetic shape memory alloys constitute an … read more NOT USED (high confidence) H. Zbib, D. Li, X. Sun, and M. Khaleel, “Large Scale DD Simulation Results for Crystal Plasticity Parameters in Fe-Cr And Fe-Ni Systems.” 2012. link Times cited: 1 Abstract: The development of viable nuclear energy source depends on e… read more NOT USED (high confidence) M. Byshkin and M. Hou, “Phase transformations and segregation in Fe–Ni alloys and nanoalloys,” Journal of Materials Science. 2012. link Times cited: 16 NOT USED (high confidence) G. Bonny, D. Terentyev, R. Pasianot, S. Poncé, and A. Bakaev, “Interatomic potential to study plasticity in stainless steels: the FeNiCr model alloy,” Modelling and Simulation in Materials Science and Engineering. 2011. link Times cited: 180 Abstract: Austenitic stainless steels are commonly used materials for … read more NOT USED (high confidence) G. Ackland, T. P. C. Klaver, and D. Hepburn, “First Principles Calculations of Defects in Unstable Crystals: Austenitic Iron,” arXiv: Materials Science. 2011. link Times cited: 0 Abstract: First principles calculations have given a new insight into … read more NOT USED (high confidence) S. Bokoch and V. Tatarenko, “Interatomic Interactions in F.C.C.-Ni–Fe Alloys.” 2010. link Times cited: 5 Abstract: The authors express their appreciation to Dr. H. M. Zapolsky… read more NOT USED (high confidence) L. Malerba et al., “Ab initio calculations and interatomic potentials for iron and iron alloys : Achievements within the Perfect Project,” Journal of Nuclear Materials. 2010. link Times cited: 65 NOT USED (high confidence) E. Beamish, C. Campañá, and T. Woo, “Grain boundary sliding in irradiated stressed Fe–Ni bicrystals: a molecular dynamics study,” Journal of Physics: Condensed Matter. 2010. link Times cited: 5 Abstract: Molecular dynamics simulations were used to model grain boun… read more NOT USED (high confidence) G. Bonny and R. Pasianot, “Gauge transformations to combine multi-component many-body interatomic potentials,” Philosophical Magazine Letters. 2010. link Times cited: 19 Abstract: Many-body interatomic potentials play an important role in a… read more NOT USED (high confidence) N. Castin and L. Malerba, “Calculation of proper energy barriers for atomistic kinetic Monte Carlo simulations on rigid lattice with chemical and strain field long-range effects using artificial neural networks.,” The Journal of chemical physics. 2010. link Times cited: 49 Abstract: In this paper we take a few steps further in the development… read more NOT USED (high confidence) G. Bonny, R. Pasianot, N. Castin, and L. Malerba, “Ternary Fe–Cu–Ni many-body potential to model reactor pressure vessel steels: First validation by simulated thermal annealing,” Philosophical Magazine. 2009. link Times cited: 206 Abstract: In recent years, the development of atomistic models dealing… read more |

| Funding | Not available |

| Short KIM ID

The unique KIM identifier code.

| MO_267721408934_005 |

| Extended KIM ID

The long form of the KIM ID including a human readable prefix (100 characters max), two underscores, and the Short KIM ID. Extended KIM IDs can only contain alpha-numeric characters (letters and digits) and underscores and must begin with a letter.

| EAM_Dynamo_BonnyPasianotMalerba_2009_FeNi__MO_267721408934_005 |

| DOI |

10.25950/e54b898a https://doi.org/10.25950/e54b898a https://commons.datacite.org/doi.org/10.25950/e54b898a |

| KIM Item Type

Specifies whether this is a Portable Model (software implementation of an interatomic model); Portable Model with parameter file (parameter file to be read in by a Model Driver); Model Driver (software implementation of an interatomic model that reads in parameters).

| Portable Model using Model Driver EAM_Dynamo__MD_120291908751_005 |

| Driver | EAM_Dynamo__MD_120291908751_005 |

| KIM API Version | 2.0 |

| Potential Type | eam |

| Previous Version | EAM_Dynamo_BonnyPasianotMalerba_2009_FeNi__MO_267721408934_004 |

| Grade | Name | Category | Brief Description | Full Results | Aux File(s) |

|---|---|---|---|---|---|

| P | vc-species-supported-as-stated | mandatory | The model supports all species it claims to support; see full description. |

Results | Files |

| P | vc-periodicity-support | mandatory | Periodic boundary conditions are handled correctly; see full description. |

Results | Files |

| P | vc-permutation-symmetry | mandatory | Total energy and forces are unchanged when swapping atoms of the same species; see full description. |

Results | Files |

| B | vc-forces-numerical-derivative | consistency | Forces computed by the model agree with numerical derivatives of the energy; see full description. |

Results | Files |

| F | vc-dimer-continuity-c1 | informational | The energy versus separation relation of a pair of atoms is C1 continuous (i.e. the function and its first derivative are continuous); see full description. |

Results | Files |

| P | vc-objectivity | informational | Total energy is unchanged and forces transform correctly under rigid-body translation and rotation; see full description. |

Results | Files |

| P | vc-inversion-symmetry | informational | Total energy is unchanged and forces change sign when inverting a configuration through the origin; see full description. |

Results | Files |

| P | vc-memory-leak | informational | The model code does not have memory leaks (i.e. it releases all allocated memory at the end); see full description. |

Results | Files |

| P | vc-thread-safe | mandatory | The model returns the same energy and forces when computed in serial and when using parallel threads for a set of configurations. Note that this is not a guarantee of thread safety; see full description. |

Results | Files |

| P | vc-unit-conversion | mandatory | The model is able to correctly convert its energy and/or forces to different unit sets; see full description. |

Results | Files |

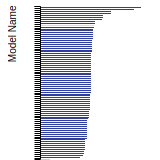

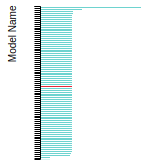

BCC Lattice Constant

This bar chart plot shows the mono-atomic body-centered cubic (bcc) lattice constant predicted by the current model (shown in the unique color) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

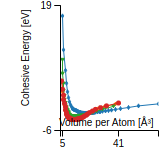

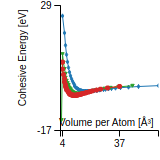

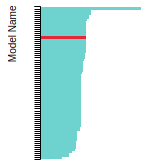

Cohesive Energy Graph

This graph shows the cohesive energy versus volume-per-atom for the current mode for four mono-atomic cubic phases (body-centered cubic (bcc), face-centered cubic (fcc), simple cubic (sc), and diamond). The curve with the lowest minimum is the ground state of the crystal if stable. (The crystal structure is enforced in these calculations, so the phase may not be stable.) Graphs are generated for each species supported by the model.

Diamond Lattice Constant

This bar chart plot shows the mono-atomic face-centered diamond lattice constant predicted by the current model (shown in the unique color) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

Dislocation Core Energies

This graph shows the dislocation core energy of a cubic crystal at zero temperature and pressure for a specific set of dislocation core cutoff radii. After obtaining the total energy of the system from conjugate gradient minimizations, non-singular, isotropic and anisotropic elasticity are applied to obtain the dislocation core energy for each of these supercells with different dipole distances. Graphs are generated for each species supported by the model.

(No matching species)FCC Elastic Constants

This bar chart plot shows the mono-atomic face-centered cubic (fcc) elastic constants predicted by the current model (shown in blue) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

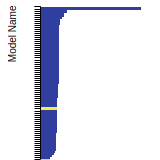

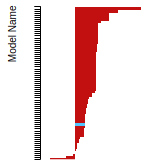

FCC Lattice Constant

This bar chart plot shows the mono-atomic face-centered cubic (fcc) lattice constant predicted by the current model (shown in red) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

FCC Stacking Fault Energies

This bar chart plot shows the intrinsic and extrinsic stacking fault energies as well as the unstable stacking and unstable twinning energies for face-centered cubic (fcc) predicted by the current model (shown in blue) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

FCC Surface Energies

This bar chart plot shows the mono-atomic face-centered cubic (fcc) relaxed surface energies predicted by the current model (shown in blue) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

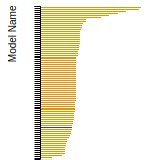

SC Lattice Constant

This bar chart plot shows the mono-atomic simple cubic (sc) lattice constant predicted by the current model (shown in the unique color) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

Cubic Crystal Basic Properties Table

Species: FeSpecies: Ni

Disclaimer From Model Developer

The potential was not stiffened to ZBL. The Fe potential is only suitable to describe alpha-Fe.

Creators:

Contributor: karls

Publication Year: 2019

DOI: https://doi.org/10.25950/64cb38c5

This Test Driver uses LAMMPS to compute the cohesive energy of a given monoatomic cubic lattice (fcc, bcc, sc, or diamond) at a variety of lattice spacings. The lattice spacings range from a_min (=a_min_frac*a_0) to a_max (=a_max_frac*a_0) where a_0, a_min_frac, and a_max_frac are read from stdin (a_0 is typically approximately equal to the equilibrium lattice constant). The precise scaling and number of lattice spacings sampled between a_min and a_0 (a_0 and a_max) is specified by two additional parameters passed from stdin: N_lower and samplespacing_lower (N_upper and samplespacing_upper). Please see README.txt for further details.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Cohesive energy versus lattice constant curve for bcc Fe v004 | view | 10846 | |

| Cohesive energy versus lattice constant curve for bcc Ni v004 | view | 6714 | |

| Cohesive energy versus lattice constant curve for diamond Fe v004 | view | 7022 | |

| Cohesive energy versus lattice constant curve for diamond Ni v004 | view | 9803 | |

| Cohesive energy versus lattice constant curve for fcc Fe v004 | view | 6455 | |

| Cohesive energy versus lattice constant curve for fcc Ni v004 | view | 6674 | |

| Cohesive energy versus lattice constant curve for sc Fe v004 | view | 9952 | |

| Cohesive energy versus lattice constant curve for sc Ni v004 | view | 6873 |

Creators:

Contributor: ilia

Publication Year: 2024

DOI: https://doi.org/10.25950/888f9943

Computes the elastic constants for an arbitrary crystal. A robust computational protocol is used, attempting multiple methods and step sizes to achieve an acceptably low error in numerical differentiation and deviation from material symmetry. The crystal structure is specified using the AFLOW prototype designation as part of the Crystal Genome testing framework. In addition, the distance from the obtained elasticity tensor to the nearest isotropic tensor is computed.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Elastic constants for FeNi in AFLOW crystal prototype A2B_cF24_227_c_b at zero temperature and pressure v000 | view | 94360 |

Creators: Junhao Li and Ellad Tadmor

Contributor: tadmor

Publication Year: 2019

DOI: https://doi.org/10.25950/5853fb8f

Computes the cubic elastic constants for some common crystal types (fcc, bcc, sc, diamond) by calculating the hessian of the energy density with respect to strain. An estimate of the error associated with the numerical differentiation performed is reported.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Elastic constants for bcc Fe at zero temperature v006 | view | 1695 | |

| Elastic constants for bcc Ni at zero temperature v006 | view | 1663 | |

| Elastic constants for fcc Fe at zero temperature v006 | view | 1951 | |

| Elastic constants for fcc Ni at zero temperature v006 | view | 1631 | |

| Elastic constants for sc Fe at zero temperature v006 | view | 3839 | |

| Elastic constants for sc Ni at zero temperature v006 | view | 1408 |

Creators: Junhao Li

Contributor: jl2922

Publication Year: 2019

DOI: https://doi.org/10.25950/d794c746

Computes the elastic constants for hcp crystals by calculating the hessian of the energy density with respect to strain. An estimate of the error associated with the numerical differentiation performed is reported.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Elastic constants for hcp Fe at zero temperature v004 | view | 1496 | |

| Elastic constants for hcp Ni at zero temperature v004 | view | 1942 |

Creators:

Contributor: ilia

Publication Year: 2024

DOI: https://doi.org/10.25950/2f2c4ad3

Computes the equilibrium crystal structure and energy for an arbitrary crystal at zero temperature and applied stress by performing symmetry-constrained relaxation. The crystal structure is specified using the AFLOW prototype designation. Multiple sets of free parameters corresponding to the crystal prototype may be specified as initial guesses for structure optimization. No guarantee is made regarding the stability of computed equilibria, nor that any are the ground state.

Creators: Brandon Runnels

Contributor: brunnels

Publication Year: 2019

DOI: https://doi.org/10.25950/4723cee7

Computes grain boundary energy for a range of tilt angles given a crystal structure, tilt axis, and material.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Relaxed energy as a function of tilt angle for a 112 symmetric tilt grain boundary in fcc Ni v000 | view | 20810545 |

Creators:

Contributor: brunnels

Publication Year: 2022

DOI: https://doi.org/10.25950/2c59c9d6

Computes grain boundary energy for a range of tilt angles given a crystal structure, tilt axis, and material.

Creators: Daniel S. Karls and Junhao Li

Contributor: karls

Publication Year: 2019

DOI: https://doi.org/10.25950/2765e3bf

Equilibrium lattice constant and cohesive energy of a cubic lattice at zero temperature and pressure.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Equilibrium zero-temperature lattice constant for bcc Fe v007 | view | 1951 | |

| Equilibrium zero-temperature lattice constant for bcc Ni v007 | view | 2335 | |

| Equilibrium zero-temperature lattice constant for diamond Fe v007 | view | 3231 | |

| Equilibrium zero-temperature lattice constant for diamond Ni v007 | view | 2975 | |

| Equilibrium zero-temperature lattice constant for fcc Fe v007 | view | 4031 | |

| Equilibrium zero-temperature lattice constant for fcc Ni v007 | view | 3711 | |

| Equilibrium zero-temperature lattice constant for sc Fe v007 | view | 2655 | |

| Equilibrium zero-temperature lattice constant for sc Ni v007 | view | 2271 |

Creators: Daniel S. Karls and Junhao Li

Contributor: karls

Publication Year: 2019

DOI: https://doi.org/10.25950/c339ca32

Calculates lattice constant of hexagonal bulk structures at zero temperature and pressure by using simplex minimization to minimize the potential energy.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Equilibrium lattice constants for hcp Fe v005 | view | 28079 | |

| Equilibrium lattice constants for hcp Ni v005 | view | 19515 |

Creators:

Contributor: mjwen

Publication Year: 2024

DOI: https://doi.org/10.25950/9d9822ec

This Test Driver uses LAMMPS to compute the linear thermal expansion coefficient at a finite temperature under a given pressure for a cubic lattice (fcc, bcc, sc, diamond) of a single given species.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Linear thermal expansion coefficient of bcc Fe at 293.15 K under a pressure of 0 MPa v002 | view | 481404 | |

| Linear thermal expansion coefficient of fcc Ni at 293.15 K under a pressure of 0 MPa v002 | view | 919888 |

Creators: Matt Bierbaum

Contributor: mattbierbaum

Publication Year: 2019

DOI: https://doi.org/10.25950/64f4999b

Calculates the phonon dispersion relations for fcc lattices and records the results as curves.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Phonon dispersion relations for fcc Ni v004 | view | 49615 |

Creators:

Contributor: SubrahmanyamPattamatta

Publication Year: 2019

DOI: https://doi.org/10.25950/b4cfaf9a

Intrinsic and extrinsic stacking fault energies, unstable stacking fault energy, unstable twinning energy, stacking fault energy as a function of fractional displacement, and gamma surface for a monoatomic FCC lattice at zero temperature and pressure.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Stacking and twinning fault energies for fcc Ni v002 | view | 6393737 |

Creators: Matt Bierbaum

Contributor: mattbierbaum

Publication Year: 2019

DOI: https://doi.org/10.25950/6c43a4e6

Calculates the surface energy of several high symmetry surfaces and produces a broken-bond model fit. In latex form, the fit equations are given by:

E_{FCC} (\vec{n}) = p_1 (4 \left( |x+y| + |x-y| + |x+z| + |x-z| + |z+y| +|z-y|\right)) + p_2 (8 \left( |x| + |y| + |z|\right)) + p_3 (2 ( |x+ 2y + z| + |x+2y-z| + |x-2y + z| + |x-2y-z| + |2x+y+z| + |2x+y-z| +|2x-y+z| +|2x-y-z| +|x+y+2z| +|x+y-2z| +|x-y+2z| +|x-y-2z| ) + c

E_{BCC} (\vec{n}) = p_1 (6 \left( | x+y+z| + |x+y-z| + |-x+y-z| + |x-y+z| \right)) + p_2 (8 \left( |x| + |y| + |z|\right)) + p_3 (4 \left( |x+y| + |x-y| + |x+z| + |x-z| + |z+y| +|z-y|\right)) +c.

In Python, these two fits take the following form:

def BrokenBondFCC(params, index):

import numpy

x, y, z = index

x = x / numpy.sqrt(x**2.+y**2.+z**2.)

y = y / numpy.sqrt(x**2.+y**2.+z**2.)

z = z / numpy.sqrt(x**2.+y**2.+z**2.)

return params[0]*4* (abs(x+y) + abs(x-y) + abs(x+z) + abs(x-z) + abs(z+y) + abs(z-y)) + params[1]*8*(abs(x) + abs(y) + abs(z)) + params[2]*(abs(x+2*y+z) + abs(x+2*y-z) +abs(x-2*y+z) +abs(x-2*y-z) + abs(2*x+y+z) +abs(2*x+y-z) +abs(2*x-y+z) +abs(2*x-y-z) + abs(x+y+2*z) +abs(x+y-2*z) +abs(x-y+2*z) +abs(x-y-2*z))+params[3]

def BrokenBondBCC(params, x, y, z):

import numpy

x, y, z = index

x = x / numpy.sqrt(x**2.+y**2.+z**2.)

y = y / numpy.sqrt(x**2.+y**2.+z**2.)

z = z / numpy.sqrt(x**2.+y**2.+z**2.)

return params[0]*6*(abs(x+y+z) + abs(x-y-z) + abs(x-y+z) + abs(x+y-z)) + params[1]*8*(abs(x) + abs(y) + abs(z)) + params[2]*4* (abs(x+y) + abs(x-y) + abs(x+z) + abs(x-z) + abs(z+y) + abs(z-y)) + params[3]

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Broken-bond fit of high-symmetry surface energies in bcc Fe v004 | view | 17914 | |

| Broken-bond fit of high-symmetry surface energies in fcc Ni v004 | view | 31477 |

Creators:

Contributor: efuem

Publication Year: 2023

DOI: https://doi.org/10.25950/fca89cea

Computes the monovacancy formation energy and relaxation volume for cubic and hcp monoatomic crystals.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Monovacancy formation energy and relaxation volume for bcc Fe | view | 382679 | |

| Monovacancy formation energy and relaxation volume for fcc Ni | view | 382311 |

Creators:

Contributor: efuem

Publication Year: 2023

DOI: https://doi.org/10.25950/c27ba3cd

Computes the monovacancy formation and migration energies for cubic and hcp monoatomic crystals.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Vacancy formation and migration energy for bcc Fe | view | 3717835 | |

| Vacancy formation and migration energy for fcc Ni | view | 1878722 |

| Test | Error Categories | Link to Error page |

|---|---|---|

| Elastic constants for diamond Fe at zero temperature v001 | other | view |

| Elastic constants for diamond Ni at zero temperature v001 | other | view |

EquilibriumCrystalStructure__TD_457028483760_002

| Test | Error Categories | Link to Error page |

|---|---|---|

| Equilibrium crystal structure and energy for Fe in AFLOW crystal prototype A_tP1_123_a v002 | other | view |

LatticeConstantCubicEnergy__TD_475411767977_006

| Test | Error Categories | Link to Error page |

|---|---|---|

| Equilibrium zero-temperature lattice constant for diamond Fe | other | view |

| Equilibrium zero-temperature lattice constant for diamond Ni | other | view |

No Driver

| Verification Check | Error Categories | Link to Error page |

|---|---|---|

| MemoryLeak__VC_561022993723_004 | other | view |

| EAM_Dynamo_BonnyPasianotMalerba_2009_FeNi__MO_267721408934_005.txz | Tar+XZ | Linux and OS X archive |

| EAM_Dynamo_BonnyPasianotMalerba_2009_FeNi__MO_267721408934_005.zip | Zip | Windows archive |

This Model requires a Model Driver. Archives for the Model Driver EAM_Dynamo__MD_120291908751_005 appear below.

| EAM_Dynamo__MD_120291908751_005.txz | Tar+XZ | Linux and OS X archive |

| EAM_Dynamo__MD_120291908751_005.zip | Zip | Windows archive |