MEAM_LAMMPS_KimJungLee_2009_FeTiC__MO_110119204723_002

MEAM_LAMMPS_KimJungLee_2009_FeTiC__MO_110119204723_002

| Title

A single sentence description.

|

MEAM Potential for the Fe-Ti-C system developed by Kim, Jung, Lee (2009) v002 |

|---|---|

| Description

A short description of the Model describing its key features including for example: type of model (pair potential, 3-body potential, EAM, etc.), modeled species (Ac, Ag, ..., Zr), intended purpose, origin, and so on.

|

Modified embedded-atom method (MEAM) interatomic potentials for the Fe–Ti–C ternary system has been developed based on the previously developed MEAM potentials for sub-unary and binary systems. The calculated coherent interface properties, interfacial energy, work of separation and misfit strain energy between body-centered cubic Fe and NaCl-type TiC is reasonable when compared with relevant first-principles calculations under the same condition. |

| Species

The supported atomic species.

| C, Fe, Ti |

| Disclaimer

A statement of applicability provided by the contributor, informing users of the intended use of this KIM Item.

|

None |

| Content Origin | http://cmse.postech.ac.kr/home_2nnmeam |

| Content Other Locations |

https://openkim.org/id/Sim_LAMMPS_MEAM_KimJungLee _2009_FeTiC__SM_531038274471_000 [openkim.org] |

| Contributor |

Joonho Ji |

| Maintainer |

Joonho Ji |

| Developer |

Hyun-Kyu Kim Woo-Sang Jung Byeong-Joo Lee |

| Published on KIM | 2023 |

| How to Cite |

This Model originally published in [1] is archived in OpenKIM [2-5]. [1] Kim H-K, Jung W-S, Lee B-J. Modified embedded-atom method interatomic potentials for the Fe–Ti–C and Fe–Ti–N ternary systems. Acta Materialia. 2009;57(11):3140–7. doi:10.1016/j.actamat.2009.03.019 — (Primary Source) A primary source is a reference directly related to the item documenting its development, as opposed to other sources that are provided as background information. [2] Kim H-K, Jung W-S, Lee B-J. MEAM Potential for the Fe-Ti-C system developed by Kim, Jung, Lee (2009) v002. OpenKIM; 2023. doi:10.25950/deddb298 [3] Afshar Y, Hütter S, Rudd RE, Stukowski A, Tipton WW, Trinkle DR, et al. The modified embedded atom method (MEAM) potential v002. OpenKIM; 2023. doi:10.25950/ee5eba52 [4] Tadmor EB, Elliott RS, Sethna JP, Miller RE, Becker CA. The potential of atomistic simulations and the Knowledgebase of Interatomic Models. JOM. 2011;63(7):17. doi:10.1007/s11837-011-0102-6 [5] Elliott RS, Tadmor EB. Knowledgebase of Interatomic Models (KIM) Application Programming Interface (API). OpenKIM; 2011. doi:10.25950/ff8f563a Click here to download the above citation in BibTeX format. |

| Citations

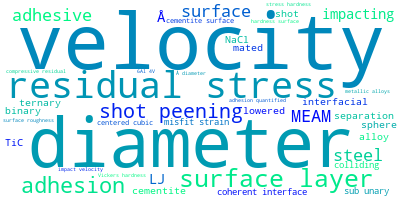

This panel presents information regarding the papers that have cited the interatomic potential (IP) whose page you are on. The OpenKIM machine learning based Deep Citation framework is used to determine whether the citing article actually used the IP in computations (denoted by "USED") or only provides it as a background citation (denoted by "NOT USED"). For more details on Deep Citation and how to work with this panel, click the documentation link at the top of the panel. The word cloud to the right is generated from the abstracts of IP principle source(s) (given below in "How to Cite") and the citing articles that were determined to have used the IP in order to provide users with a quick sense of the types of physical phenomena to which this IP is applied. The bar chart shows the number of articles that cited the IP per year. Each bar is divided into green (articles that USED the IP) and blue (articles that did NOT USE the IP). Users are encouraged to correct Deep Citation errors in determination by clicking the speech icon next to a citing article and providing updated information. This will be integrated into the next Deep Citation learning cycle, which occurs on a regular basis. OpenKIM acknowledges the support of the Allen Institute for AI through the Semantic Scholar project for providing citation information and full text of articles when available, which are used to train the Deep Citation ML algorithm. |

This panel provides information on past usage of this interatomic potential (IP) powered by the OpenKIM Deep Citation framework. The word cloud indicates typical applications of the potential. The bar chart shows citations per year of this IP (bars are divided into articles that used the IP (green) and those that did not (blue)). The complete list of articles that cited this IP is provided below along with the Deep Citation determination on usage. See the Deep Citation documentation for more information.

119 Citations (86 used)

Help us to determine which of the papers that cite this potential actually used it to perform calculations. If you know, click the .

USED (definite) A. Al-Motasem, “Influence of Alloying Additives on The Adhesive Properties of Steels: Atomic Level Simulation,” JOURNAL OF ADVANCES IN PHYSICS. 2018. link Times cited: 0 Abstract: In the present work we report atomistic molecular dynamics s… read more USED (high confidence) B. Waters, D. S. Karls, I. Nikiforov, R. Elliott, E. Tadmor, and B. Runnels, “Automated determination of grain boundary energy and potential-dependence using the OpenKIM framework,” Computational Materials Science. 2022. link Times cited: 5 USED (high confidence) H. Zhang, A. Pan, R. Hei, and P. Liu, “An atomistic simulation on the tensile and compressive deformation mechanisms of nano-polycrystalline Ti,” Applied Physics A. 2021. link Times cited: 3 USED (high confidence) E. Mahdavi, M. Haghighi‐Yazdi, M. M. Mashhadi, and R. Khaledialidusti, “Effects of interlayer density and surfactant on coupled thermal stress and moisture absorption in modified montmorillonite/polypropylene nanocomposite,” Journal of Applied Polymer Science. 2020. link Times cited: 0 USED (high confidence) I. Salehinia, S. Shao, J. Wang, and H. Zbib, “Interface structure and the inception of plasticity in Nb/NbC nanolayered composites,” Acta Materialia. 2015. link Times cited: 89 USED (high confidence) I. Salehinia, S. Shao, J. Wang, and H. Zbib, “Plastic Deformation of Metal/Ceramic Nanolayered Composites,” JOM. 2014. link Times cited: 60 USED (high confidence) J. Chun and B. Lee, “Atomistic calculations of mechanical properties of Ni-Ti-C metallic glass systems,” Journal of Mechanical Science and Technology. 2013. link Times cited: 3 USED (high confidence) A. Moradi, A. Heidari, K. Amini, F. Aghadavoudi, and R. Abedinzadeh, “Molecular modeling of Ti-6Al-4V alloy shot peening: the effects of diameter and velocity of shot particles and force field on mechanical properties and residual stress,” Modelling and Simulation in Materials Science and Engineering. 2021. link Times cited: 12 Abstract: Shot peening is a surface treatment process that is used for… read more USED (low confidence) A. Goncharov, A. Yunda, I. Kolinko, G. Kornich, and D. Shyrokorad, “Modeling the Deposition of Thin Films of Transition Metal Nitrides,” Coatings. 2023. link Times cited: 0 Abstract: This paper presents an overview of studies dedicated to the … read more USED (low confidence) R. J. Slooter, M. H. F. Sluiter, W. G. T. Kranendonk, and C. Bos, “Atomistic simulation of carbide formation in ferrite,” Computational Materials Science. 2023. link Times cited: 0 USED (low confidence) X. Fan, S. Gao, J. Zhang, and K. Jiao, “Analysis of the structure and viscosity of iron melts containing titanium at various concentration,” Journal of Molecular Liquids. 2023. link Times cited: 1 USED (low confidence) J. Li, S. Yang, L. Dong, J. Zhang, Z. Zheng, and J. Liu, “Effect of crystal orientation on the nanoindentation deformation behavior of TiN coating based on molecular dynamics,” Surface and Coatings Technology. 2023. link Times cited: 0 USED (low confidence) C. Tsai, C.-H. Tung, C.-C. Chen, and S.-Y. Chang, “Chemical Complexity-Changed Deformation Behavior of NiTi-Based B2 Low- to High-Entropy Intermetallic Compounds: Atomistic Simulations,” Journal of Alloys and Compounds. 2023. link Times cited: 0 USED (low confidence) H. Peng et al., “New insights into the adsorption of Fe on Ti(CxN1−x) surface: First-principles study,” Materials Today Communications. 2023. link Times cited: 2 USED (low confidence) S. E. Restrepo and P. Andric, “ABC-FIRE: Accelerated Bias-Corrected Fast Inertial Relaxation Engine,” Computational Materials Science. 2023. link Times cited: 0 USED (low confidence) P. Olsson, P. Hiremath, and S. Melin, “Atomistic investigation of the impact of phosphorus impurities on the tungsten grain boundary decohesion,” Computational Materials Science. 2023. link Times cited: 2 USED (low confidence) S. E. Restrepo, P. Andric, and A. Paxton, “Effect of crystal defects in iron on carbon diffusivity: Analytical model married to atomistics,” Physical Review Materials. 2022. link Times cited: 1 USED (low confidence) J.-Y. Tian, B.-jie Ding, C. Xie, M. Zhang, and J.-K. Du, “Interaction between Grain Dislocation and Symmetrical Tilt Grain Boundary in TiC Single Crystal,” 2022 16th Symposium on Piezoelectricity, Acoustic Waves, and Device Applications (SPAWDA). 2022. link Times cited: 0 Abstract: Dislocation movement is closely related to the plastic defor… read more USED (low confidence) G. Xiang, X. Luo, T. Cao, A. Zhang, and H. Yu, “Atomic Diffusion and Crystal Structure Evolution at the Fe-Ti Interface: Molecular Dynamics Simulations,” Materials. 2022. link Times cited: 4 Abstract: The diffusion bonding method is one of the most essential ma… read more USED (low confidence) Y. Lei et al., “An Embedded-Atom Method Potential for studying the properties of Fe-Pb solid-liquid interface,” Journal of Nuclear Materials. 2022. link Times cited: 1 USED (low confidence) M. Wu et al., “Research on the Lattice Matching of Different Solute Atoms in BCC Fe: A Molecular Dynamics Simulation,” Crystal Research and Technology. 2022. link Times cited: 0 Abstract: In this article, molecular dynamics simulation is used to pr… read more USED (low confidence) S. Xu, W. Wu, J. Chang, S. Sha, and B. Wei, “Duplex Solidification Mechanisms of Glass Forming Zr55Cu30Al10Ni5 Alloy During Electromagnetic Levitation Processing,” Metallurgical and Materials Transactions A. 2022. link Times cited: 3 USED (low confidence) M. B. Nasiri and F. Iranshahi, “Comprehensive unified model and simulation approach for microstructure evolution,” ChemPhysMater. 2021. link Times cited: 2 USED (low confidence) P. Huo, Z. Zhao, W. Du, Z. Zhang, P. Bai, and D. Tie, “Deformation strengthening mechanism of in situ TiC/TC4 alloy nanocomposites produced by selective laser melting,” Composites Part B: Engineering. 2021. link Times cited: 26 USED (low confidence) S. Lv, J. Li, S. Li, N. Kang, and B. Chen, “Effects of heat treatment on interfacial characteristics and mechanical properties of titanium matrix composites reinforced with discontinuous carbon fibers,” Journal of Alloys and Compounds. 2021. link Times cited: 4 USED (low confidence) Z. Wu, R. Wang, L. Zhu, S. Pattamatta, and D. Srolov, “Revealing and Controlling the Core of Screw Dislocations in BCC Metals.” 2021. link Times cited: 0 Abstract:

Body-centred-cubic (BCC) transition metals (TMs) tend to b… read more USED (low confidence) W. Choi et al., “Computational design of V-CoCrFeMnNi high-entropy alloys: An atomistic simulation study,” Calphad-computer Coupling of Phase Diagrams and Thermochemistry. 2021. link Times cited: 12 USED (low confidence) A. Bhowmik, W. Zhai, W. Zhou, and S. Nai, “Characterization of carbide particle-reinforced 316L stainless steel fabricated by selective laser melting,” Materials Characterization. 2021. link Times cited: 11 USED (low confidence) D. Yang, Y. Sun, Z. Yang, X. Chen, and C. Wang, “Multiscale modeling of unidirectional composites with interfacial debonding using molecular dynamics and micromechanics,” Composites Part B-engineering. 2021. link Times cited: 7 USED (low confidence) H. Amini, P. Gholizadeh, E. Poursaeidi, and J. Davoodi, “A molecular dynamics simulation of Ti–TiN multilayer deposition on FeCrNi(001) alloy substrate,” Vacuum. 2021. link Times cited: 4 USED (low confidence) Y. Yang, M. Liu, S. Zhou, W. Ren, Q. Zhou, and S. Lan, “Breaking through the strength-ductility trade-off in graphene reinforced Ti6Al4V composites,” Journal of Alloys and Compounds. 2021. link Times cited: 22 USED (low confidence) A. Agrawal and R. Mirzaeifar, “Copper-graphene composites; developing the MEAM potential and investigating their mechanical properties,” Computational Materials Science. 2021. link Times cited: 9 USED (low confidence) C. Han et al., “Microstructure and mechanical properties of (TiB+TiC)/Ti composites fabricated in situ via selective laser melting of Ti and B4C powders,” Additive manufacturing. 2020. link Times cited: 98 USED (low confidence) A. S. M. Miraz, N. Dhariwal, W. Meng, B. Ramachandran, and C. Wick, “Development and application of interatomic potentials to study the stability and shear strength of Ti/TiN and Cu/TiN interfaces,” Materials & Design. 2020. link Times cited: 15 USED (low confidence) L. E. Atouani, K. Sbiaai, and A. Hasnaoui, “Insights into NinTim clusters adsorption and diffusion on B2-NiTi phase from atomistic simulations,” Surface Science. 2020. link Times cited: 2 USED (low confidence) H.-S. Jang, D. Seol, and B.-J. Lee, “Modified embedded-atom method interatomic potentials for Mg–Al–Ca and Mg–Al–Zn ternary systems,” Journal of Magnesium and Alloys. 2020. link Times cited: 28 USED (low confidence) P. Liu, J. Xie, A. Wang, M. Douqin, and Z. Mao, “Molecular dynamics simulation on the deformation mechanism of monocrystalline and nano-twinned TiN under nanoindentation,” Materials Chemistry and Physics. 2020. link Times cited: 14 USED (low confidence) N. Yang, W. Huang, and D. Lei, “Control of nanoscale material removal in diamond polishing by using iron at low temperature,” Journal of Materials Processing Technology. 2020. link Times cited: 14 USED (low confidence) S. Ding and X.-qiang Wang, “Strain rate and temperature effects on the mechanical properties of TiN/VN composite: Molecular dynamics study,” Journal of Alloys and Compounds. 2020. link Times cited: 7 USED (low confidence) H.-S. Jang, D. Seol, and B.-J. Lee, “Modified embedded-atom method interatomic potential for the Mg–Zn–Ca ternary system,” Calphad-computer Coupling of Phase Diagrams and Thermochemistry. 2019. link Times cited: 6 USED (low confidence) I. Aslam et al., “Thermodynamic and kinetic behavior of low-alloy steels: An atomic level study using an Fe-Mn-Si-C modified embedded atom method (MEAM) potential,” Materialia. 2019. link Times cited: 12 USED (low confidence) S. Ding and X.-qiang Wang, “A systematic study on the MEAM interatomic potentials of the transition metal nitrides TMNs (TM=Ti, V, Cr, Fe) binary systems,” Journal of Alloys and Compounds. 2019. link Times cited: 10 USED (low confidence) N. Mediukh, V. Ivashchenko, P. Turchi, V. Shevchenko, J. Leszczynski, and L. Gorb, “Phase diagrams and mechanical properties of TiC-SiC solid solutions from first-principles,” Calphad. 2019. link Times cited: 3 USED (low confidence) S. M. Zamzamian, S. Feghhi, M. Samadfam, and M. Darvishzadeh, “Atomistic investigation of the effects of symmetric tilt grain boundary structures on irradiation response of the α-Fe containing carbon in solution,” Computational Materials Science. 2019. link Times cited: 4 USED (low confidence) L. Zhang, Y. Wu, W. Yu, and S. Shen, “Response of <110> symmetric tilt grain boundary in titanium nitride under shear,” Engineering Analysis with Boundary Elements. 2019. link Times cited: 9 USED (low confidence) L. E. Atouani, E. E. koraychy, K. Sbiaai, M. Mazroui, and A. Hasnaoui, “Cluster adsorption and migration energetics on hcp Ti (0001) surfaces via atomistic simulations,” Thin Solid Films. 2019. link Times cited: 8 USED (low confidence) S. Rogachev, “Applicability of molecular dynamics method to the prediction of the melting point of refractory metals and compounds,” IOP Conference Series: Materials Science and Engineering. 2019. link Times cited: 3 Abstract: Various methods for measuring the melting point using embedd… read more USED (low confidence) Y. Pachaury and Y. Shin, “Assessment of sub-surface damage during machining of additively manufactured Fe-TiC metal matrix composites,” Journal of Materials Processing Technology. 2019. link Times cited: 21 USED (low confidence) L. Zhang, L. Wang, W. Yu, S. Shen, and T. Fu, “Structure and shear response of <001> tilt grain boundary in titanium nitride,” Ceramics International. 2019. link Times cited: 9 USED (low confidence) H. Wang, J. Zhao, W. Liu, and B. Wei, “An anomalous thermal expansion phenomenon induced by phase transition of Fe-Co-Ni alloys,” Journal of Applied Physics. 2018. link Times cited: 5 Abstract: The thermal expansion and the phase transition of Fe-15.6 wt… read more USED (low confidence) L. Du, L. Wang, W. Zhai, L. Hu, J. Liu, and B. Wei, “Liquid state property, structural evolution and mechanical behavior of Ti Fe alloy solidified under electrostatic levitation condition,” Materials & Design. 2018. link Times cited: 7 USED (low confidence) W. Yang, G. Ayoub, I. Salehinia, B. Mansoor, and H. Zbib, “The effect of layer thickness ratio on the plastic deformation mechanisms of nanoindented Ti/TiN nanolayered composite,” Computational Materials Science. 2018. link Times cited: 18 USED (low confidence) M. Elkhateeb and Y. Shin, “Molecular dynamics-based cohesive zone representation of Ti6Al4V/TiC composite interface,” Materials & Design. 2018. link Times cited: 43 USED (low confidence) X. Fan, S. Wang, X. Yang, G. Ni, J. Zhang, and D. Li, “Bonding characteristic and electronic property of TiC_xN_1−x(001)/TiC(001) interface: A first-principles study,” Journal of Materials Research. 2018. link Times cited: 4 Abstract: The TiC_ x N_1− x (001)/TiC(001) interface was studied by th… read more USED (low confidence) F. Zhang, M. Yan, F. Yin, Y. Wang, Y. Zhang, and J. He, “Influence of plasma nitriding temperature on microstructures and mechanical properties of Ti-N/Ti-Al multilayer coatings on the surface of 5083 Al alloys,” Surface & Coatings Technology. 2018. link Times cited: 11 USED (low confidence) P. Ghosh, K. Ali, A. Vineet, A. Voleti, and A. Arya, “Study of structural, mechanical and thermal properties of θ-Fe3C, o-Fe7C3 and h-Fe7C3 phases using molecular dynamics simulations,” Journal of Alloys and Compounds. 2017. link Times cited: 12 USED (low confidence) Y.-K. Kim, H. Kim, W. Jung, and B.-J. Lee, “Development and application of Ni-Ti and Ni-Al-Ti 2NN-MEAM interatomic potentials for Ni-base superalloys,” Computational Materials Science. 2017. link Times cited: 24 USED (low confidence) X. Zhang et al., “Mechanical failure of metal/ceramic interfacial regions under shear loading,” Acta Materialia. 2017. link Times cited: 53 USED (low confidence) C.-jun Wu, B.-J. Lee, and X. Su, “Modified embedded-atom interatomic potential for Fe-Ni, Cr-Ni and Fe-Cr-Ni systems,” Calphad-computer Coupling of Phase Diagrams and Thermochemistry. 2017. link Times cited: 60 USED (low confidence) C. Feng, X. Peng, T. Fu, Y. Zhao, C. Huang, and Z. Wang, “Molecular dynamics simulation of nano-indentation on Ti-V multilayered thin films,” Physica E-low-dimensional Systems & Nanostructures. 2017. link Times cited: 16 USED (low confidence) G. B. Souza, S. H. Gonsalves, K. Ribeiro, D. G. Ditzel, M. Ueda, and W. Schreiner, “Physical and chemical effects of the hydrogen irradiation on nitrided titanium surfaces,” Surface & Coatings Technology. 2017. link Times cited: 5 USED (low confidence) F. Xingwen, C. Bing, Z. Minmin, L. Da, L. Zan, and X. Changyuan, “First-principles calculations on bonding characteristic and electronic property of TiC (111)/TiN (111) interface,” Materials & Design. 2016. link Times cited: 52 USED (low confidence) M. Trybula, “Structure and transport properties of the liquid Al80Cu20 alloy – A molecular dynamics study,” Computational Materials Science. 2016. link Times cited: 22 USED (low confidence) Y. Chen, H. Du, M. Chen, J. Yang, J. Xiong, and H. Zhao, “Structure and wear behavior of AlCrSiN-based coatings,” Applied Surface Science. 2016. link Times cited: 28 USED (low confidence) W. Dong, “Atomistic Calculations of Interface Properties for Co-Al-W Alloys.” 2016. link Times cited: 1 USED (low confidence) V. Mishra and S. Chaturvedi, “First-principles study of high temperature and high-pressure behavior of carbides and nitrides of group IVB elements,” Phase Transitions. 2016. link Times cited: 3 Abstract: Full potential linearized augmented plane wave method combin… read more USED (low confidence) T. Fu et al., “Molecular dynamics simulation of TiN (001) thin films under indentation,” Ceramics International. 2015. link Times cited: 48 USED (low confidence) A. P. Moore, B. Beeler, C. Deo, M. Baskes, and M. Okuniewski, “Atomistic modeling of high temperature uranium–zirconium alloy structure and thermodynamics,” Journal of Nuclear Materials. 2015. link Times cited: 41 USED (low confidence) T. Fu, X. Peng, C. Feng, Y. Zhao, and Z. Wang, “MD simulation of growth of Pd on Cu (1 1 1) and Cu on Pd (1 1 1) substrates,” Applied Surface Science. 2015. link Times cited: 19 USED (low confidence) D. Edström, D. Sangiovanni, L. Hultman, I. Petrov, J. Greene, and V. Chirita, “The dynamics of TiNx (x = 1–3) admolecule interlayer and intralayer transport on TiN/TiN(001) islands,” Thin Solid Films. 2015. link Times cited: 12 USED (low confidence) W. Dong, Z. Chen, and B.-J. Lee, “Modified embedded-atom interatomic potential for Co–W and Al–W systems,” Transactions of Nonferrous Metals Society of China. 2015. link Times cited: 9 USED (low confidence) Y.-xia Liu, H. Wang, H. Wu, D. Xu, and R. Yang, “A mean-field interatomic potential for a multi-component β-type titanium alloy,” Computational Materials Science. 2014. link Times cited: 2 USED (low confidence) T. A. Timmerscheidt, J. Appen, and R. Dronskowski, “A molecular-dynamics study on carbon diffusion in face-centered cubic iron,” Computational Materials Science. 2014. link Times cited: 14 USED (low confidence) J. Shim et al., “Prediction of hydrogen permeability in V–Al and V–Ni alloys,” Journal of Membrane Science. 2013. link Times cited: 21 USED (low confidence) W. Dong, Z. Jing, and Z. Chen, “Atomic Interchange Potentials Calculation of Ni-Al-Cr Alloy Based on Microscopic Phase Field Method,” Materials Science Forum. 2013. link Times cited: 0 Abstract: The effects of increasing atomic interchange potentials to t… read more USED (low confidence) W. Dong, H.-K. Kim, W. Ko, B.-M. Lee, and B.-J. Lee, “Atomistic modeling of pure Co and Co–Al system,” Calphad-computer Coupling of Phase Diagrams and Thermochemistry. 2012. link Times cited: 42 USED (low confidence) W. Qin, N. Kumar, J. Szpunar, and J. Kozinski, “Intergranular δ-hydride nucleation and orientation in zirconium alloys,” Acta Materialia. 2011. link Times cited: 76 USED (low confidence) B. Jelinek et al., “Modified embedded atom method potential for Al, Si, Mg, Cu, and Fe alloys,” Physical Review B. 2011. link Times cited: 218 Abstract: A set of modified embedded-atom method (MEAM) potentials for… read more USED (low confidence) B.-J. Lee, W. Ko, H.-K. Kim, and E.-H. Kim, “The modified embedded-atom method interatomic potentials and recent progress in atomistic simulations,” Calphad-computer Coupling of Phase Diagrams and Thermochemistry. 2010. link Times cited: 137 USED (low confidence) Y.-M. Kim, N. Kim, and B.-J. Lee, “Atomistic Modeling of pure Mg and Mg―Al systems,” Calphad-computer Coupling of Phase Diagrams and Thermochemistry. 2009. link Times cited: 119 USED (low confidence) K. Kang, I. Sa, J.-C. Lee, E. Fleury, and B.-J. Lee, “Atomistic modeling of the Cu-Zr-Ag bulk metallic glass system,” Scripta Materialia. 2009. link Times cited: 26 USED (low confidence) I. Shabalin, “Ultra-High Temperature Materials III: Refractory Carbides II (Ti and V Carbides),” Ultra-High Temperature Materials III. 2020. link Times cited: 3 USED (low confidence) I. Shabalin, “Titanium Monocarbide,” Ultra-High Temperature Materials III. 2020. link Times cited: 5 USED (low confidence) W. Meng and S. Shao, “Experimentation and Modeling of Mechanical Integrity and Instability at Metal/Ceramic Interfaces.” 2018. link Times cited: 1 USED (low confidence) T. Prasanthi, C. Sudha, S. Saroja, and M. Vijayalakshmi, “Simulation of nitrogen diffusion in Ni vis-à-vis Fe – Identification of better structural material for neutron detectors,” Results in physics. 2014. link Times cited: 3 USED (low confidence) Y. Lv, P. Hodgson, L. Kong, and W. Gao, “Molecular dynamics modelling of diffusional formation of titanium carbide clusters in iron matrix.” 2014. link Times cited: 0 NOT USED (low confidence) H. Xiang and W. Guo, “A newly developed interatomic potential of Nb−Al−Ti ternary systems for high-temperature applications,” Acta Mechanica Sinica. 2022. link Times cited: 5 NOT USED (low confidence) H. Xiang and W. Guo, “A newly developed interatomic potential of Nb−Al−Ti ternary systems for high-temperature applications,” Acta Mechanica Sinica. 2022. link Times cited: 0 NOT USED (low confidence) P. Liu, J. Xie, A. Wang, D. Ma, and Z. Mao, “An interatomic potential for accurately describing the atomic-scale deformation behaviors of Ti2AlC crystal,” Computational Materials Science. 2020. link Times cited: 10 NOT USED (high confidence) S. Ding, Y. Li, Y. Luo, Z. Wu, and X. Wang, “Modified Embedded-Atom Interatomic Potential Parameters of the Ti–Cr Binary and Ti–Cr–N Ternary Systems,” Frontiers in Chemistry. 2021. link Times cited: 1 Abstract: The second nearest-neighbor modified embedded-atom method (2… read more NOT USED (high confidence) D. Lubyanoi, A. Markidonov, E. Pudov, V. Shakhmanov, E. Kuzin, and O. S. Semenova, “Efficient Technologies for Producing Cast Iron Billets and Products with Specified Properties and Microstructure,” IOP Conference Series: Materials Science and Engineering. 2021. link Times cited: 1 Abstract: The article discusses the use of resonant-pulsating refining… read more NOT USED (high confidence) X. W. Zhou, M. E. Foster, J. Ronevich, and C. S. Marchi, “Review and construction of interatomic potentials for molecular dynamics studies of hydrogen embrittlement in Fe─C based steels,” Journal of Computational Chemistry. 2020. link Times cited: 7 Abstract: Reducing hydrogen embrittlement in the low‐cost Fe─C based s… read more NOT USED (high confidence) X. Yang, J.-hua Hu, and W. Jiang, “Stability and interatomic potentials for M-doped TiV alloys (M=H, He, C, O) by first-principles simulations,” The European Physical Journal D. 2019. link Times cited: 4 NOT USED (high confidence) Y. Zhang et al., “Molecular‐Scale Modeling and Multiscale Experiments on the Elastic Properties of HR‐2 Steel Affected by Hydrogen,” steel research international. 2019. link Times cited: 0 Abstract: Austenitic stainless steel is used in hydrogen containers. T… read more NOT USED (high confidence) G. Almyras, D. Sangiovanni, and K. Sarakinos, “Semi-Empirical Force-Field Model for the Ti1−xAlxN (0 ≤ x ≤ 1) System,” Materials. 2019. link Times cited: 21 Abstract: We present a modified embedded atom method (MEAM) semi-empir… read more NOT USED (high confidence) D. Dickel, C. Barrett, R. Cariño, M. Baskes, and M. Horstemeyer, “Mechanical instabilities in the modeling of phase transitions of titanium,” Modelling and Simulation in Materials Science and Engineering. 2018. link Times cited: 16 Abstract: In this paper, we demonstrate that previously observed β to … read more NOT USED (high confidence) T. Prasanthi, C. Sudha, and S. Saroja, “Molecular Dynamics Simulation of Diffusion of Fe in HCP Ti Lattice,” Transactions of the Indian Institute of Metals. 2018. link Times cited: 2 NOT USED (high confidence) W. Choi, Y. Jo, S. Sohn, S. Lee, and B.-J. Lee, “Understanding the physical metallurgy of the CoCrFeMnNi high-entropy alloy: an atomistic simulation study,” npj Computational Materials. 2018. link Times cited: 436 NOT USED (high confidence) F. Montero-Chacón et al., “Multiscale thermo-mechanical analysis of multi-layered coatings in solar thermal applications,” Finite Elements in Analysis and Design. 2017. link Times cited: 16 NOT USED (high confidence) N. Chistyakova and T. M. Tran, “A study of the applicability of different types of interatomic potentials to compute elastic properties of metals with molecular dynamics methods.” 2016. link Times cited: 6 Abstract: The paper describes three common types of interatomic intera… read more NOT USED (high confidence) K. Tong, F. Ye, M. Gao, M. Lei, and C. Zhang, “Interatomic potential for Fe–Cr–Ni–N system based on the second nearest-neighbor modified embedded-atom method,” Molecular Simulation. 2016. link Times cited: 7 Abstract: The interatomic potential for Fe–Cr–Ni–N system based on the… read more NOT USED (high confidence) T. Liang et al., “Properties of Ti/TiC Interfaces from Molecular Dynamics Simulations,” Journal of Physical Chemistry C. 2016. link Times cited: 25 Abstract: Titanium carbide is used as a primary component in coating m… read more NOT USED (high confidence) V. Borysiuk, V. Mochalin, and Y. Gogotsi, “Molecular dynamic study of the mechanical properties of two-dimensional titanium carbides Tin+1Cn (MXenes),” Nanotechnology. 2015. link Times cited: 190 Abstract: Two-dimensional materials beyond graphene are attracting muc… read more NOT USED (high confidence) Y.-K. Kim, W. Jung, and B.-J. Lee, “Modified embedded-atom method interatomic potentials for the Ni–Co binary and the Ni–Al–Co ternary systems,” Modelling and Simulation in Materials Science and Engineering. 2015. link Times cited: 32 Abstract: Interatomic potentials for the Ni–Co binary and Ni–Al–Co ter… read more NOT USED (high confidence) M. Trybula, N. Jakse, W. Gasior, and A. Pasturel, “Structural and physicochemical properties of liquid Al-Zn alloys: a combined study based on molecular dynamics simulations and the quasi-lattice theory.,” The Journal of chemical physics. 2014. link Times cited: 15 Abstract: Ordering phenomena have been investigated in liquid Al-Zn al… read more NOT USED (high confidence) W. Dong, B.-J. Lee, and Z. Chen, “Atomistic modeling for interfacial properties of Ni-Al-V ternary system,” Metals and Materials International. 2014. link Times cited: 6 NOT USED (high confidence) B.-M. Lee and B.-J. Lee, “A Comparative Study on Hydrogen Diffusion in Amorphous and Crystalline Metals Using a Molecular Dynamics Simulation,” Metallurgical and Materials Transactions A. 2014. link Times cited: 35 NOT USED (high confidence) W. Ko and B.-J. Lee, “Modified embedded-atom method interatomic potentials for pure Y and the V–Pd–Y ternary system,” Modelling and Simulation in Materials Science and Engineering. 2013. link Times cited: 20 Abstract: Interatomic potentials for pure Y and the V–Pd–Y ternary sys… read more NOT USED (high confidence) H. Gao, A. Otero-de-la-Roza, S. Aouadi, E. Johnson, and A. Martini, “An empirical model for silver tantalate,” Modelling and Simulation in Materials Science and Engineering. 2013. link Times cited: 13 Abstract: A set of parameters for the modified embedded atom method (M… read more NOT USED (high confidence) S. Nouranian, M. Tschopp, M. Tschopp, S. Gwaltney, M. Baskes, and M. Horstemeyer, “An interatomic potential for saturated hydrocarbons based on the modified embedded-atom method.,” Physical chemistry chemical physics : PCCP. 2013. link Times cited: 39 Abstract: In this work, we developed an interatomic potential for satu… read more NOT USED (high confidence) C. Henager, F. Gao, S. Hu, G. Lin, E. Bylaska, and N. Zabaras, “Simulating Interface Growth and Defect Generation in CZT – Simulation State of the Art and Known Gaps.” 2012. link Times cited: 1 Abstract: This one-year, study topic project will survey and investiga… read more NOT USED (high confidence) Y. Li et al., “Elastic and thermodynamic properties of TiC from first-principles calculations,” Science China Physics, Mechanics and Astronomy. 2011. link Times cited: 31 NOT USED (high confidence) W. Dong, Y. Wang, K. Yang, Z. Chen, and Y. Lu, “Phase field simulation of interatomic potentials for double phase competition during early stage precipitation,” Chinese Science Bulletin. 2011. link Times cited: 5 NOT USED (high confidence) K. Kádas, O. Eriksson, and N. Skorodumova, “Highly anisotropic sliding at TiN/Fe interfaces: A first principles study,” Journal of Applied Physics. 2010. link Times cited: 10 Abstract: By means of first principles density functional theory, we i… read more NOT USED (high confidence) H.-K. Kim, W. Jung, and B.-J. Lee, “Modified embedded-atom method interatomic potentials for the Nb-C, Nb-N, Fe-Nb-C, and Fe-Nb-N systems,” Journal of Materials Research. 2010. link Times cited: 21 Abstract: Modified embedded-atom method (MEAM) interatomic potentials … read more NOT USED (high confidence) E. C. Do, Y.-H. Shin, and B.-J. Lee, “Atomistic modeling of III–V nitrides: modified embedded-atom method interatomic potentials for GaN, InN and Ga1−xInxN,” Journal of Physics: Condensed Matter. 2009. link Times cited: 26 Abstract: Modified embedded-atom method (MEAM) interatomic potentials … read more NOT USED (high confidence) N. Razmara and R. Mohammadzadeh, “Molecular dynamics study of nitrogen diffusion in nanocrystalline iron,” Journal of Molecular Modeling. 2016. link Times cited: 6 NOT USED (high confidence) W. Joost, S. Ankem, and M. Kuklja, “A modified embedded atom method potential for the titanium–oxygen system,” Modelling and Simulation in Materials Science and Engineering. 2014. link Times cited: 16 Abstract: Small concentrations of impurity atoms can affect the behavi… read more NOT USED (definite) J. J. Moller et al., “110

planar faults in strained bcc metals: Origins and implications of a commonly observed artifact of classical potentials,” Physical Review Materials. 2018. link Times cited: 18 Abstract: Large-scale atomistic simulations with classical potentials … read more |

| Funding | Not available |

| Short KIM ID

The unique KIM identifier code.

| MO_110119204723_002 |

| Extended KIM ID

The long form of the KIM ID including a human readable prefix (100 characters max), two underscores, and the Short KIM ID. Extended KIM IDs can only contain alpha-numeric characters (letters and digits) and underscores and must begin with a letter.

| MEAM_LAMMPS_KimJungLee_2009_FeTiC__MO_110119204723_002 |

| DOI |

10.25950/deddb298 https://doi.org/10.25950/deddb298 https://commons.datacite.org/doi.org/10.25950/deddb298 |

| KIM Item Type

Specifies whether this is a Portable Model (software implementation of an interatomic model); Portable Model with parameter file (parameter file to be read in by a Model Driver); Model Driver (software implementation of an interatomic model that reads in parameters).

| Portable Model using Model Driver MEAM_LAMMPS__MD_249792265679_002 |

| Driver | MEAM_LAMMPS__MD_249792265679_002 |

| KIM API Version | 2.2 |

| Potential Type | meam |

| Previous Version | MEAM_LAMMPS_KimJungLee_2009_FeTiC__MO_110119204723_001 |

| Grade | Name | Category | Brief Description | Full Results | Aux File(s) |

|---|---|---|---|---|---|

| P | vc-species-supported-as-stated | mandatory | The model supports all species it claims to support; see full description. |

Results | Files |

| P | vc-periodicity-support | mandatory | Periodic boundary conditions are handled correctly; see full description. |

Results | Files |

| P | vc-permutation-symmetry | mandatory | Total energy and forces are unchanged when swapping atoms of the same species; see full description. |

Results | Files |

| N/A | vc-dimer-continuity-c1 | informational | The energy versus separation relation of a pair of atoms is C1 continuous (i.e. the function and its first derivative are continuous); see full description. |

Results | Files |

| P | vc-objectivity | informational | Total energy is unchanged and forces transform correctly under rigid-body translation and rotation; see full description. |

Results | Files |

| P | vc-inversion-symmetry | informational | Total energy is unchanged and forces change sign when inverting a configuration through the origin; see full description. |

Results | Files |

| P | vc-memory-leak | informational | The model code does not have memory leaks (i.e. it releases all allocated memory at the end); see full description. |

Results | Files |

| P | vc-thread-safe | mandatory | The model returns the same energy and forces when computed in serial and when using parallel threads for a set of configurations. Note that this is not a guarantee of thread safety; see full description. |

Results | Files |

| P | vc-unit-conversion | mandatory | The model is able to correctly convert its energy and/or forces to different unit sets; see full description. |

Results | Files |

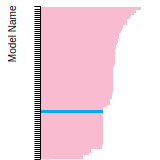

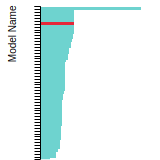

BCC Lattice Constant

This bar chart plot shows the mono-atomic body-centered cubic (bcc) lattice constant predicted by the current model (shown in the unique color) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

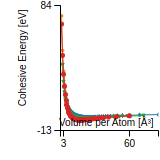

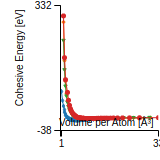

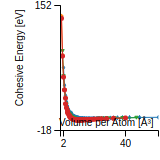

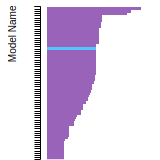

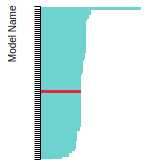

Cohesive Energy Graph

This graph shows the cohesive energy versus volume-per-atom for the current mode for four mono-atomic cubic phases (body-centered cubic (bcc), face-centered cubic (fcc), simple cubic (sc), and diamond). The curve with the lowest minimum is the ground state of the crystal if stable. (The crystal structure is enforced in these calculations, so the phase may not be stable.) Graphs are generated for each species supported by the model.

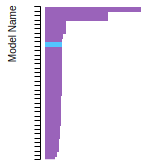

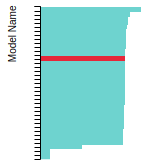

Diamond Lattice Constant

This bar chart plot shows the mono-atomic face-centered diamond lattice constant predicted by the current model (shown in the unique color) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

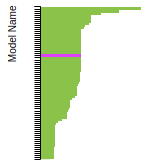

Dislocation Core Energies

This graph shows the dislocation core energy of a cubic crystal at zero temperature and pressure for a specific set of dislocation core cutoff radii. After obtaining the total energy of the system from conjugate gradient minimizations, non-singular, isotropic and anisotropic elasticity are applied to obtain the dislocation core energy for each of these supercells with different dipole distances. Graphs are generated for each species supported by the model.

(No matching species)FCC Elastic Constants

This bar chart plot shows the mono-atomic face-centered cubic (fcc) elastic constants predicted by the current model (shown in blue) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

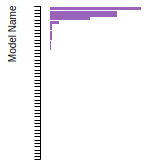

FCC Lattice Constant

This bar chart plot shows the mono-atomic face-centered cubic (fcc) lattice constant predicted by the current model (shown in red) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

FCC Stacking Fault Energies

This bar chart plot shows the intrinsic and extrinsic stacking fault energies as well as the unstable stacking and unstable twinning energies for face-centered cubic (fcc) predicted by the current model (shown in blue) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

(No matching species)FCC Surface Energies

This bar chart plot shows the mono-atomic face-centered cubic (fcc) relaxed surface energies predicted by the current model (shown in blue) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

(No matching species)SC Lattice Constant

This bar chart plot shows the mono-atomic simple cubic (sc) lattice constant predicted by the current model (shown in the unique color) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

Cubic Crystal Basic Properties Table

Species: CSpecies: Fe

Species: Ti

Creators:

Contributor: karls

Publication Year: 2019

DOI: https://doi.org/10.25950/64cb38c5

This Test Driver uses LAMMPS to compute the cohesive energy of a given monoatomic cubic lattice (fcc, bcc, sc, or diamond) at a variety of lattice spacings. The lattice spacings range from a_min (=a_min_frac*a_0) to a_max (=a_max_frac*a_0) where a_0, a_min_frac, and a_max_frac are read from stdin (a_0 is typically approximately equal to the equilibrium lattice constant). The precise scaling and number of lattice spacings sampled between a_min and a_0 (a_0 and a_max) is specified by two additional parameters passed from stdin: N_lower and samplespacing_lower (N_upper and samplespacing_upper). Please see README.txt for further details.

Creators:

Contributor: ilia

Publication Year: 2024

DOI: https://doi.org/10.25950/888f9943

Computes the elastic constants for an arbitrary crystal. A robust computational protocol is used, attempting multiple methods and step sizes to achieve an acceptably low error in numerical differentiation and deviation from material symmetry. The crystal structure is specified using the AFLOW prototype designation as part of the Crystal Genome testing framework. In addition, the distance from the obtained elasticity tensor to the nearest isotropic tensor is computed.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Elastic constants for CFe in AFLOW crystal prototype A2B5_mC28_15_f_e2f at zero temperature and pressure v000 | view | 1701738 | |

| Elastic constants for FeTi in AFLOW crystal prototype A2B_hP12_194_ah_f at zero temperature and pressure v000 | view | 473017 |

Creators: Junhao Li and Ellad Tadmor

Contributor: tadmor

Publication Year: 2019

DOI: https://doi.org/10.25950/5853fb8f

Computes the cubic elastic constants for some common crystal types (fcc, bcc, sc, diamond) by calculating the hessian of the energy density with respect to strain. An estimate of the error associated with the numerical differentiation performed is reported.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Elastic constants for bcc C at zero temperature v006 | view | 28386 | |

| Elastic constants for bcc Fe at zero temperature v006 | view | 32822 | |

| Elastic constants for bcc Ti at zero temperature v006 | view | 37755 | |

| Elastic constants for fcc C at zero temperature v006 | view | 44099 | |

| Elastic constants for fcc Fe at zero temperature v006 | view | 35411 | |

| Elastic constants for fcc Ti at zero temperature v006 | view | 46086 | |

| Elastic constants for sc C at zero temperature v006 | view | 29918 | |

| Elastic constants for sc Fe at zero temperature v006 | view | 31141 | |

| Elastic constants for sc Ti at zero temperature v006 | view | 27471 |

Creators:

Contributor: ilia

Publication Year: 2024

DOI: https://doi.org/10.25950/2f2c4ad3

Computes the equilibrium crystal structure and energy for an arbitrary crystal at zero temperature and applied stress by performing symmetry-constrained relaxation. The crystal structure is specified using the AFLOW prototype designation. Multiple sets of free parameters corresponding to the crystal prototype may be specified as initial guesses for structure optimization. No guarantee is made regarding the stability of computed equilibria, nor that any are the ground state.

Creators:

Contributor: ilia

Publication Year: 2025

DOI: https://doi.org/10.25950/866c7cfa

Computes the equilibrium crystal structure and energy for an arbitrary crystal at zero temperature and applied stress by performing symmetry-constrained relaxation. The crystal structure is specified using the AFLOW prototype designation. Multiple sets of free parameters corresponding to the crystal prototype may be specified as initial guesses for structure optimization. No guarantee is made regarding the stability of computed equilibria, nor that any are the ground state.

Creators:

Contributor: brunnels

Publication Year: 2022

DOI: https://doi.org/10.25950/2c59c9d6

Computes grain boundary energy for a range of tilt angles given a crystal structure, tilt axis, and material.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Relaxed energy as a function of tilt angle for a 100 symmetric tilt grain boundary in bcc Fe v001 | view | 32520645 | |

| Relaxed energy as a function of tilt angle for a 111 symmetric tilt grain boundary in bcc Fe v001 | view | 56955749 | |

| Relaxed energy as a function of tilt angle for a 100 symmetric tilt grain boundary in fcc Fe v001 | view | 39977917 |

Creators: Ilia Nikiforov

Contributor: ilia

Publication Year: 2019

DOI: https://doi.org/10.25950/dd36239b

Given atomic species and structure type (graphene-like, 2H, or 1T) of a 2D hexagonal monolayer crystal, as well as an initial guess at the lattice spacing, this Test Driver calculates the equilibrium lattice spacing and cohesive energy using Polak-Ribiere conjugate gradient minimization in LAMMPS

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Cohesive energy and equilibrium lattice constant of graphene v002 | view | 1031 |

Creators: Daniel S. Karls and Junhao Li

Contributor: karls

Publication Year: 2019

DOI: https://doi.org/10.25950/2765e3bf

Equilibrium lattice constant and cohesive energy of a cubic lattice at zero temperature and pressure.

Creators: Daniel S. Karls and Junhao Li

Contributor: karls

Publication Year: 2019

DOI: https://doi.org/10.25950/c339ca32

Calculates lattice constant of hexagonal bulk structures at zero temperature and pressure by using simplex minimization to minimize the potential energy.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Equilibrium lattice constants for hcp C v005 | view | 288096 | |

| Equilibrium lattice constants for hcp Fe v005 | view | 268850 | |

| Equilibrium lattice constants for hcp Ti v005 | view | 277036 |

Creators:

Contributor: mjwen

Publication Year: 2024

DOI: https://doi.org/10.25950/9d9822ec

This Test Driver uses LAMMPS to compute the linear thermal expansion coefficient at a finite temperature under a given pressure for a cubic lattice (fcc, bcc, sc, diamond) of a single given species.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Linear thermal expansion coefficient of bcc Fe at 293.15 K under a pressure of 0 MPa v002 | view | 7260454 | |

| Linear thermal expansion coefficient of diamond C at 293.15 K under a pressure of 0 MPa v002 | view | 13169305 |

Creators: Matt Bierbaum

Contributor: mattbierbaum

Publication Year: 2019

DOI: https://doi.org/10.25950/6c43a4e6

Calculates the surface energy of several high symmetry surfaces and produces a broken-bond model fit. In latex form, the fit equations are given by:

E_{FCC} (\vec{n}) = p_1 (4 \left( |x+y| + |x-y| + |x+z| + |x-z| + |z+y| +|z-y|\right)) + p_2 (8 \left( |x| + |y| + |z|\right)) + p_3 (2 ( |x+ 2y + z| + |x+2y-z| + |x-2y + z| + |x-2y-z| + |2x+y+z| + |2x+y-z| +|2x-y+z| +|2x-y-z| +|x+y+2z| +|x+y-2z| +|x-y+2z| +|x-y-2z| ) + c

E_{BCC} (\vec{n}) = p_1 (6 \left( | x+y+z| + |x+y-z| + |-x+y-z| + |x-y+z| \right)) + p_2 (8 \left( |x| + |y| + |z|\right)) + p_3 (4 \left( |x+y| + |x-y| + |x+z| + |x-z| + |z+y| +|z-y|\right)) +c.

In Python, these two fits take the following form:

def BrokenBondFCC(params, index):

import numpy

x, y, z = index

x = x / numpy.sqrt(x**2.+y**2.+z**2.)

y = y / numpy.sqrt(x**2.+y**2.+z**2.)

z = z / numpy.sqrt(x**2.+y**2.+z**2.)

return params[0]*4* (abs(x+y) + abs(x-y) + abs(x+z) + abs(x-z) + abs(z+y) + abs(z-y)) + params[1]*8*(abs(x) + abs(y) + abs(z)) + params[2]*(abs(x+2*y+z) + abs(x+2*y-z) +abs(x-2*y+z) +abs(x-2*y-z) + abs(2*x+y+z) +abs(2*x+y-z) +abs(2*x-y+z) +abs(2*x-y-z) + abs(x+y+2*z) +abs(x+y-2*z) +abs(x-y+2*z) +abs(x-y-2*z))+params[3]

def BrokenBondBCC(params, x, y, z):

import numpy

x, y, z = index

x = x / numpy.sqrt(x**2.+y**2.+z**2.)

y = y / numpy.sqrt(x**2.+y**2.+z**2.)

z = z / numpy.sqrt(x**2.+y**2.+z**2.)

return params[0]*6*(abs(x+y+z) + abs(x-y-z) + abs(x-y+z) + abs(x+y-z)) + params[1]*8*(abs(x) + abs(y) + abs(z)) + params[2]*4* (abs(x+y) + abs(x-y) + abs(x+z) + abs(x-z) + abs(z+y) + abs(z-y)) + params[3]

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Broken-bond fit of high-symmetry surface energies in bcc Fe v004 | view | 102285 |

Creators:

Contributor: efuem

Publication Year: 2023

DOI: https://doi.org/10.25950/fca89cea

Computes the monovacancy formation energy and relaxation volume for cubic and hcp monoatomic crystals.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Monovacancy formation energy and relaxation volume for bcc Fe | view | 961999 | |

| Monovacancy formation energy and relaxation volume for hcp Ti | view | 404545 |

Creators:

Contributor: efuem

Publication Year: 2023

DOI: https://doi.org/10.25950/c27ba3cd

Computes the monovacancy formation and migration energies for cubic and hcp monoatomic crystals.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Vacancy formation and migration energy for bcc Fe | view | 762046 | |

| Vacancy formation and migration energy for hcp Ti | view | 4294063 |

| Test | Error Categories | Link to Error page |

|---|---|---|

| Elastic constants for diamond C at zero temperature v001 | other | view |

| Elastic constants for diamond Fe at zero temperature v001 | other | view |

| Elastic constants for diamond Ti at zero temperature v001 | other | view |

ElasticConstantsHexagonal__TD_612503193866_004

| Test | Error Categories | Link to Error page |

|---|---|---|

| Elastic constants for hcp C at zero temperature v004 | other | view |

| Elastic constants for hcp Fe at zero temperature v004 | other | view |

| Elastic constants for hcp Ti at zero temperature v004 | other | view |

EquilibriumCrystalStructure__TD_457028483760_000

EquilibriumCrystalStructure__TD_457028483760_002

EquilibriumCrystalStructure__TD_457028483760_003

GrainBoundaryCubicCrystalSymmetricTiltRelaxedEnergyVsAngle__TD_410381120771_003

LinearThermalExpansionCoeffCubic__TD_522633393614_001

| Test | Error Categories | Link to Error page |

|---|---|---|

| Linear thermal expansion coefficient of diamond C at 293.15 K under a pressure of 0 MPa v001 | other | view |

SurfaceEnergyCubicCrystalBrokenBondFit__TD_955413365818_004

| Test | Error Categories | Link to Error page |

|---|---|---|

| Broken-bond fit of high-symmetry surface energies in bcc Fe v004 | other | view |

No Driver

| Verification Check | Error Categories | Link to Error page |

|---|---|---|

| DimerContinuityC1__VC_303890932454_005 | other | view |

| ForcesNumerDeriv__VC_710586816390_003 | other | view |

| MEAM_LAMMPS_KimJungLee_2009_FeTiC__MO_110119204723_002.txz | Tar+XZ | Linux and OS X archive |

| MEAM_LAMMPS_KimJungLee_2009_FeTiC__MO_110119204723_002.zip | Zip | Windows archive |

This Model requires a Model Driver. Archives for the Model Driver MEAM_LAMMPS__MD_249792265679_002 appear below.

| MEAM_LAMMPS__MD_249792265679_002.txz | Tar+XZ | Linux and OS X archive |

| MEAM_LAMMPS__MD_249792265679_002.zip | Zip | Windows archive |