EAM_Dynamo_LiuLiuBorucki_1999_AlCu__MO_020851069572_000

EAM_Dynamo_LiuLiuBorucki_1999_AlCu__MO_020851069572_000

| Title

A single sentence description.

|

EAM potential (LAMMPS cubic hermite tabulation) for the Al-Cu system developed by Liu et al. (1999) v000 |

|---|---|

| Description

A short description of the Model describing its key features including for example: type of model (pair potential, 3-body potential, EAM, etc.), modeled species (Ac, Ag, ..., Zr), intended purpose, origin, and so on.

|

EAM potential for the Al-Cu system developed by Liu et al. (1999). The potential was used to study electromigration in Al-Cu interconnects. |

| Species

The supported atomic species.

| Al, Cu |

| Disclaimer

A statement of applicability provided by the contributor, informing users of the intended use of this KIM Item.

|

None |

| Content Origin | NIST IPRP (https://www.ctcms.nist.gov/potentials/Al.html#Al-Cu) |

| Content Other Locations | http://enpub.fulton.asu.edu/cms/potentials/main/main.htm |

| Contributor |

Ellad B. Tadmor |

| Maintainer |

Ellad B. Tadmor |

| Developer |

Chunli Liu Leonard Borucki XY Liu |

| Published on KIM | 2018 |

| How to Cite | Click here to download this citation in BibTeX format. |

| Citations

This panel presents information regarding the papers that have cited the interatomic potential (IP) whose page you are on. The OpenKIM machine learning based Deep Citation framework is used to determine whether the citing article actually used the IP in computations (denoted by "USED") or only provides it as a background citation (denoted by "NOT USED"). For more details on Deep Citation and how to work with this panel, click the documentation link at the top of the panel. The word cloud to the right is generated from the abstracts of IP principle source(s) (given below in "How to Cite") and the citing articles that were determined to have used the IP in order to provide users with a quick sense of the types of physical phenomena to which this IP is applied. The bar chart shows the number of articles that cited the IP per year. Each bar is divided into green (articles that USED the IP) and blue (articles that did NOT USE the IP). Users are encouraged to correct Deep Citation errors in determination by clicking the speech icon next to a citing article and providing updated information. This will be integrated into the next Deep Citation learning cycle, which occurs on a regular basis. OpenKIM acknowledges the support of the Allen Institute for AI through the Semantic Scholar project for providing citation information and full text of articles when available, which are used to train the Deep Citation ML algorithm. |

This panel provides information on past usage of this interatomic potential (IP) powered by the OpenKIM Deep Citation framework. The word cloud indicates typical applications of the potential. The bar chart shows citations per year of this IP (bars are divided into articles that used the IP (green) and those that did not (blue)). The complete list of articles that cited this IP is provided below along with the Deep Citation determination on usage. See the Deep Citation documentation for more information.

Help us to determine which of the papers that cite this potential actually used it to perform calculations. If you know, click the .

|

| Funding | Not available |

| Short KIM ID

The unique KIM identifier code.

| MO_020851069572_000 |

| Extended KIM ID

The long form of the KIM ID including a human readable prefix (100 characters max), two underscores, and the Short KIM ID. Extended KIM IDs can only contain alpha-numeric characters (letters and digits) and underscores and must begin with a letter.

| EAM_Dynamo_LiuLiuBorucki_1999_AlCu__MO_020851069572_000 |

| DOI |

10.25950/2dd77629 https://doi.org/10.25950/2dd77629 https://commons.datacite.org/doi.org/10.25950/2dd77629 |

| KIM Item Type

Specifies whether this is a Portable Model (software implementation of an interatomic model); Portable Model with parameter file (parameter file to be read in by a Model Driver); Model Driver (software implementation of an interatomic model that reads in parameters).

| Portable Model using Model Driver EAM_Dynamo__MD_120291908751_005 |

| Driver | EAM_Dynamo__MD_120291908751_005 |

| KIM API Version | 2.0 |

| Potential Type | eam |

| Grade | Name | Category | Brief Description | Full Results | Aux File(s) |

|---|---|---|---|---|---|

| P | vc-species-supported-as-stated | mandatory | The model supports all species it claims to support; see full description. |

Results | Files |

| P | vc-periodicity-support | mandatory | Periodic boundary conditions are handled correctly; see full description. |

Results | Files |

| P | vc-permutation-symmetry | mandatory | Total energy and forces are unchanged when swapping atoms of the same species; see full description. |

Results | Files |

| B | vc-forces-numerical-derivative | consistency | Forces computed by the model agree with numerical derivatives of the energy; see full description. |

Results | Files |

| F | vc-dimer-continuity-c1 | informational | The energy versus separation relation of a pair of atoms is C1 continuous (i.e. the function and its first derivative are continuous); see full description. |

Results | Files |

| P | vc-objectivity | informational | Total energy is unchanged and forces transform correctly under rigid-body translation and rotation; see full description. |

Results | Files |

| P | vc-inversion-symmetry | informational | Total energy is unchanged and forces change sign when inverting a configuration through the origin; see full description. |

Results | Files |

| P | vc-memory-leak | informational | The model code does not have memory leaks (i.e. it releases all allocated memory at the end); see full description. |

Results | Files |

| P | vc-thread-safe | mandatory | The model returns the same energy and forces when computed in serial and when using parallel threads for a set of configurations. Note that this is not a guarantee of thread safety; see full description. |

Results | Files |

| P | vc-unit-conversion | mandatory | The model is able to correctly convert its energy and/or forces to different unit sets; see full description. |

Results | Files |

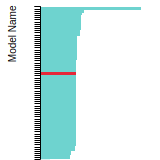

BCC Lattice Constant

This bar chart plot shows the mono-atomic body-centered cubic (bcc) lattice constant predicted by the current model (shown in the unique color) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

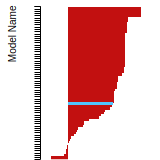

Cohesive Energy Graph

This graph shows the cohesive energy versus volume-per-atom for the current mode for four mono-atomic cubic phases (body-centered cubic (bcc), face-centered cubic (fcc), simple cubic (sc), and diamond). The curve with the lowest minimum is the ground state of the crystal if stable. (The crystal structure is enforced in these calculations, so the phase may not be stable.) Graphs are generated for each species supported by the model.

Diamond Lattice Constant

This bar chart plot shows the mono-atomic face-centered diamond lattice constant predicted by the current model (shown in the unique color) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

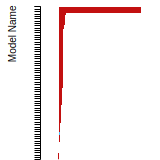

Dislocation Core Energies

This graph shows the dislocation core energy of a cubic crystal at zero temperature and pressure for a specific set of dislocation core cutoff radii. After obtaining the total energy of the system from conjugate gradient minimizations, non-singular, isotropic and anisotropic elasticity are applied to obtain the dislocation core energy for each of these supercells with different dipole distances. Graphs are generated for each species supported by the model.

(No matching species)FCC Elastic Constants

This bar chart plot shows the mono-atomic face-centered cubic (fcc) elastic constants predicted by the current model (shown in blue) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

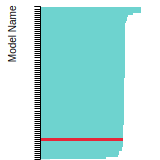

FCC Lattice Constant

This bar chart plot shows the mono-atomic face-centered cubic (fcc) lattice constant predicted by the current model (shown in red) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

FCC Stacking Fault Energies

This bar chart plot shows the intrinsic and extrinsic stacking fault energies as well as the unstable stacking and unstable twinning energies for face-centered cubic (fcc) predicted by the current model (shown in blue) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

FCC Surface Energies

This bar chart plot shows the mono-atomic face-centered cubic (fcc) relaxed surface energies predicted by the current model (shown in blue) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

SC Lattice Constant

This bar chart plot shows the mono-atomic simple cubic (sc) lattice constant predicted by the current model (shown in the unique color) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

Cubic Crystal Basic Properties Table

Species: AlSpecies: Cu

Creators:

Contributor: karls

Publication Year: 2019

DOI: https://doi.org/10.25950/64cb38c5

This Test Driver uses LAMMPS to compute the cohesive energy of a given monoatomic cubic lattice (fcc, bcc, sc, or diamond) at a variety of lattice spacings. The lattice spacings range from a_min (=a_min_frac*a_0) to a_max (=a_max_frac*a_0) where a_0, a_min_frac, and a_max_frac are read from stdin (a_0 is typically approximately equal to the equilibrium lattice constant). The precise scaling and number of lattice spacings sampled between a_min and a_0 (a_0 and a_max) is specified by two additional parameters passed from stdin: N_lower and samplespacing_lower (N_upper and samplespacing_upper). Please see README.txt for further details.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Cohesive energy versus lattice constant curve for bcc Al v004 | view | 2974 | |

| Cohesive energy versus lattice constant curve for bcc Cu v004 | view | 3243 | |

| Cohesive energy versus lattice constant curve for diamond Al v004 | view | 3004 | |

| Cohesive energy versus lattice constant curve for diamond Cu v004 | view | 2596 | |

| Cohesive energy versus lattice constant curve for fcc Al v004 | view | 4361 | |

| Cohesive energy versus lattice constant curve for fcc Cu v004 | view | 4510 | |

| Cohesive energy versus lattice constant curve for sc Al v004 | view | 2705 | |

| Cohesive energy versus lattice constant curve for sc Cu v004 | view | 3392 |

Creators: Junhao Li and Ellad Tadmor

Contributor: tadmor

Publication Year: 2019

DOI: https://doi.org/10.25950/5853fb8f

Computes the cubic elastic constants for some common crystal types (fcc, bcc, sc, diamond) by calculating the hessian of the energy density with respect to strain. An estimate of the error associated with the numerical differentiation performed is reported.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Elastic constants for bcc Al at zero temperature v006 | view | 1408 | |

| Elastic constants for bcc Cu at zero temperature v006 | view | 1855 | |

| Elastic constants for fcc Al at zero temperature v006 | view | 3903 | |

| Elastic constants for fcc Cu at zero temperature v006 | view | 1919 | |

| Elastic constants for sc Al at zero temperature v006 | view | 1983 | |

| Elastic constants for sc Cu at zero temperature v006 | view | 1919 |

Creators: Junhao Li

Contributor: jl2922

Publication Year: 2019

DOI: https://doi.org/10.25950/d794c746

Computes the elastic constants for hcp crystals by calculating the hessian of the energy density with respect to strain. An estimate of the error associated with the numerical differentiation performed is reported.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Elastic constants for hcp Al at zero temperature v004 | view | 1305 | |

| Elastic constants for hcp Cu at zero temperature v004 | view | 1846 |

Creators:

Contributor: ilia

Publication Year: 2023

DOI: https://doi.org/10.25950/e8a7ed84

Computes the equilibrium crystal structure and energy for an arbitrary crystal at zero temperature and applied stress by performing symmetry-constrained relaxation. The crystal structure is specified using the AFLOW prototype designation. Multiple sets of free parameters corresponding to the crystal prototype may be specified as initial guesses for structure optimization. No guarantee is made regarding the stability of computed equilibria, nor that any are the ground state.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Equilibrium crystal structure and energy for Cu in AFLOW crystal prototype A_cF4_225_a v001 | view | 58749 | |

| Equilibrium crystal structure and energy for Cu in AFLOW crystal prototype A_cI2_229_a v001 | view | 54258 |

Creators:

Contributor: ilia

Publication Year: 2024

DOI: https://doi.org/10.25950/2f2c4ad3

Computes the equilibrium crystal structure and energy for an arbitrary crystal at zero temperature and applied stress by performing symmetry-constrained relaxation. The crystal structure is specified using the AFLOW prototype designation. Multiple sets of free parameters corresponding to the crystal prototype may be specified as initial guesses for structure optimization. No guarantee is made regarding the stability of computed equilibria, nor that any are the ground state.

Creators:

Contributor: ilia

Publication Year: 2025

DOI: https://doi.org/10.25950/866c7cfa

Computes the equilibrium crystal structure and energy for an arbitrary crystal at zero temperature and applied stress by performing symmetry-constrained relaxation. The crystal structure is specified using the AFLOW prototype designation. Multiple sets of free parameters corresponding to the crystal prototype may be specified as initial guesses for structure optimization. No guarantee is made regarding the stability of computed equilibria, nor that any are the ground state.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Equilibrium crystal structure and energy for Al in AFLOW crystal prototype A_cF4_225_a v003 | view | 144001 | |

| Equilibrium crystal structure and energy for Al in AFLOW crystal prototype A_cI2_229_a v003 | view | 218672 |

Creators:

Contributor: brunnels

Publication Year: 2022

DOI: https://doi.org/10.25950/2c59c9d6

Computes grain boundary energy for a range of tilt angles given a crystal structure, tilt axis, and material.

Creators: Daniel S. Karls and Junhao Li

Contributor: karls

Publication Year: 2019

DOI: https://doi.org/10.25950/2765e3bf

Equilibrium lattice constant and cohesive energy of a cubic lattice at zero temperature and pressure.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Equilibrium zero-temperature lattice constant for bcc Al v007 | view | 1791 | |

| Equilibrium zero-temperature lattice constant for bcc Cu v007 | view | 1823 | |

| Equilibrium zero-temperature lattice constant for diamond Al v007 | view | 2079 | |

| Equilibrium zero-temperature lattice constant for diamond Cu v007 | view | 2655 | |

| Equilibrium zero-temperature lattice constant for fcc Al v007 | view | 3839 | |

| Equilibrium zero-temperature lattice constant for fcc Cu v007 | view | 3327 | |

| Equilibrium zero-temperature lattice constant for sc Al v007 | view | 1759 | |

| Equilibrium zero-temperature lattice constant for sc Cu v007 | view | 2271 |

Creators: Daniel S. Karls and Junhao Li

Contributor: karls

Publication Year: 2019

DOI: https://doi.org/10.25950/c339ca32

Calculates lattice constant of hexagonal bulk structures at zero temperature and pressure by using simplex minimization to minimize the potential energy.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Equilibrium lattice constants for hcp Al v005 | view | 15440 | |

| Equilibrium lattice constants for hcp Cu v005 | view | 23750 |

Creators: Mingjian Wen

Contributor: mjwen

Publication Year: 2019

DOI: https://doi.org/10.25950/fc69d82d

This Test Driver uses LAMMPS to compute the linear thermal expansion coefficient at a finite temperature under a given pressure for a cubic lattice (fcc, bcc, sc, diamond) of a single given species.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Linear thermal expansion coefficient of fcc Cu at 293.15 K under a pressure of 0 MPa v001 | view | 4360133 |

Creators:

Contributor: mjwen

Publication Year: 2024

DOI: https://doi.org/10.25950/9d9822ec

This Test Driver uses LAMMPS to compute the linear thermal expansion coefficient at a finite temperature under a given pressure for a cubic lattice (fcc, bcc, sc, diamond) of a single given species.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Linear thermal expansion coefficient of fcc Al at 293.15 K under a pressure of 0 MPa v002 | view | 725015 |

Creators: Matt Bierbaum

Contributor: mattbierbaum

Publication Year: 2019

DOI: https://doi.org/10.25950/64f4999b

Calculates the phonon dispersion relations for fcc lattices and records the results as curves.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Phonon dispersion relations for fcc Al v004 | view | 49679 | |

| Phonon dispersion relations for fcc Cu v004 | view | 50223 |

Creators:

Contributor: SubrahmanyamPattamatta

Publication Year: 2019

DOI: https://doi.org/10.25950/b4cfaf9a

Intrinsic and extrinsic stacking fault energies, unstable stacking fault energy, unstable twinning energy, stacking fault energy as a function of fractional displacement, and gamma surface for a monoatomic FCC lattice at zero temperature and pressure.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Stacking and twinning fault energies for fcc Al v002 | view | 5147382 | |

| Stacking and twinning fault energies for fcc Cu v002 | view | 5777981 |

Creators: Matt Bierbaum

Contributor: mattbierbaum

Publication Year: 2019

DOI: https://doi.org/10.25950/6c43a4e6

Calculates the surface energy of several high symmetry surfaces and produces a broken-bond model fit. In latex form, the fit equations are given by:

E_{FCC} (\vec{n}) = p_1 (4 \left( |x+y| + |x-y| + |x+z| + |x-z| + |z+y| +|z-y|\right)) + p_2 (8 \left( |x| + |y| + |z|\right)) + p_3 (2 ( |x+ 2y + z| + |x+2y-z| + |x-2y + z| + |x-2y-z| + |2x+y+z| + |2x+y-z| +|2x-y+z| +|2x-y-z| +|x+y+2z| +|x+y-2z| +|x-y+2z| +|x-y-2z| ) + c

E_{BCC} (\vec{n}) = p_1 (6 \left( | x+y+z| + |x+y-z| + |-x+y-z| + |x-y+z| \right)) + p_2 (8 \left( |x| + |y| + |z|\right)) + p_3 (4 \left( |x+y| + |x-y| + |x+z| + |x-z| + |z+y| +|z-y|\right)) +c.

In Python, these two fits take the following form:

def BrokenBondFCC(params, index):

import numpy

x, y, z = index

x = x / numpy.sqrt(x**2.+y**2.+z**2.)

y = y / numpy.sqrt(x**2.+y**2.+z**2.)

z = z / numpy.sqrt(x**2.+y**2.+z**2.)

return params[0]*4* (abs(x+y) + abs(x-y) + abs(x+z) + abs(x-z) + abs(z+y) + abs(z-y)) + params[1]*8*(abs(x) + abs(y) + abs(z)) + params[2]*(abs(x+2*y+z) + abs(x+2*y-z) +abs(x-2*y+z) +abs(x-2*y-z) + abs(2*x+y+z) +abs(2*x+y-z) +abs(2*x-y+z) +abs(2*x-y-z) + abs(x+y+2*z) +abs(x+y-2*z) +abs(x-y+2*z) +abs(x-y-2*z))+params[3]

def BrokenBondBCC(params, x, y, z):

import numpy

x, y, z = index

x = x / numpy.sqrt(x**2.+y**2.+z**2.)

y = y / numpy.sqrt(x**2.+y**2.+z**2.)

z = z / numpy.sqrt(x**2.+y**2.+z**2.)

return params[0]*6*(abs(x+y+z) + abs(x-y-z) + abs(x-y+z) + abs(x+y-z)) + params[1]*8*(abs(x) + abs(y) + abs(z)) + params[2]*4* (abs(x+y) + abs(x-y) + abs(x+z) + abs(x-z) + abs(z+y) + abs(z-y)) + params[3]

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Broken-bond fit of high-symmetry surface energies in fcc Al v004 | view | 22168 | |

| Broken-bond fit of high-symmetry surface energies in fcc Cu v004 | view | 27159 |

Creators:

Contributor: efuem

Publication Year: 2023

DOI: https://doi.org/10.25950/fca89cea

Computes the monovacancy formation energy and relaxation volume for cubic and hcp monoatomic crystals.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Monovacancy formation energy and relaxation volume for fcc Al | view | 321648 | |

| Monovacancy formation energy and relaxation volume for fcc Cu | view | 352348 |

Creators:

Contributor: efuem

Publication Year: 2023

DOI: https://doi.org/10.25950/c27ba3cd

Computes the monovacancy formation and migration energies for cubic and hcp monoatomic crystals.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Vacancy formation and migration energy for fcc Al | view | 976429 | |

| Vacancy formation and migration energy for fcc Cu | view | 2101571 |

| Test | Error Categories | Link to Error page |

|---|---|---|

| Elastic constants for diamond Al at zero temperature v001 | other | view |

| Elastic constants for diamond Cu at zero temperature v001 | other | view |

LatticeConstantCubicEnergy__TD_475411767977_006

| Test | Error Categories | Link to Error page |

|---|---|---|

| Equilibrium zero-temperature lattice constant for diamond Al | other | view |

| Equilibrium zero-temperature lattice constant for diamond Cu | other | view |

No Driver

| Verification Check | Error Categories | Link to Error page |

|---|---|---|

| DimerContinuityC1__VC_303890932454_005 | other | view |

| EAM_Dynamo_LiuLiuBorucki_1999_AlCu__MO_020851069572_000.txz | Tar+XZ | Linux and OS X archive |

| EAM_Dynamo_LiuLiuBorucki_1999_AlCu__MO_020851069572_000.zip | Zip | Windows archive |

This Model requires a Model Driver. Archives for the Model Driver EAM_Dynamo__MD_120291908751_005 appear below.

| EAM_Dynamo__MD_120291908751_005.txz | Tar+XZ | Linux and OS X archive |

| EAM_Dynamo__MD_120291908751_005.zip | Zip | Windows archive |