EAM_Dynamo_PunYamakovMishin_2013_NiAlCo__MO_826591359508_000

EAM_Dynamo_PunYamakovMishin_2013_NiAlCo__MO_826591359508_000

| Title

A single sentence description.

|

EAM potential (LAMMPS cubic hermite tabulation) for the Ni-Al-Co system developed by Pun, Yamakov and Mishin (2013) v000 |

|---|---|

| Description

A short description of the Model describing its key features including for example: type of model (pair potential, 3-body potential, EAM, etc.), modeled species (Ac, Ag, ..., Zr), intended purpose, origin, and so on.

|

EAM potential for the Ni-Al-Co system developed by Pun, Yamakov and Mishin (2013) by fitting to experimental and first-principles data. Reasonably good agreement is achieved for physical properties between values predicted by the potential and values known from experiment and/or first-principles calculations. The potential reproduces basic features of the martensitic phase transformation from the B2-ordered high-temperature phase to a tetragonal CuAu-ordered low-temperature phase. The compositional and temperature ranges of this transformation and the martensite microstructure predicted by the potential compare well with existing experimental data. These results indicate that the proposed potential can be used for simulations of the shape memory effect in the Ni–Al–Co system. |

| Species

The supported atomic species.

| Al, Co, Ni |

| Disclaimer

A statement of applicability provided by the contributor, informing users of the intended use of this KIM Item.

|

None |

| Content Origin | NIST IPRP (https://www.ctcms.nist.gov/potentials/Al.html#Al-Co-Ni) |

| Contributor |

Ellad B. Tadmor |

| Maintainer |

Ellad B. Tadmor |

| Developer |

Vesselin Yamakov Yuri Mishin Ganga P. Purja Pun |

| Published on KIM | 2018 |

| How to Cite |

This Model originally published in [1] is archived in OpenKIM [2-5]. [1] Pun GPP, Yamakov V, Mishin Y. Interatomic potential for the ternary Ni–Al–Co system and application to atomistic modeling of the B2–L1 0 martensitic transformation. Modelling and Simulation in Materials Science and Engineering. 2015;23(6):065006. doi:10.1088/0965-0393/23/6/065006 — (Primary Source) A primary source is a reference directly related to the item documenting its development, as opposed to other sources that are provided as background information. [2] Yamakov V, Mishin Y, Pun GPP. EAM potential (LAMMPS cubic hermite tabulation) for the Ni-Al-Co system developed by Pun, Yamakov and Mishin (2013) v000. OpenKIM; 2018. doi:10.25950/48e9959e [3] Foiles SM, Baskes MI, Daw MS, Plimpton SJ. EAM Model Driver for tabulated potentials with cubic Hermite spline interpolation as used in LAMMPS v005. OpenKIM; 2018. doi:10.25950/68defa36 [4] Tadmor EB, Elliott RS, Sethna JP, Miller RE, Becker CA. The potential of atomistic simulations and the Knowledgebase of Interatomic Models. JOM. 2011;63(7):17. doi:10.1007/s11837-011-0102-6 [5] Elliott RS, Tadmor EB. Knowledgebase of Interatomic Models (KIM) Application Programming Interface (API). OpenKIM; 2011. doi:10.25950/ff8f563a Click here to download the above citation in BibTeX format. |

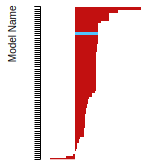

| Citations

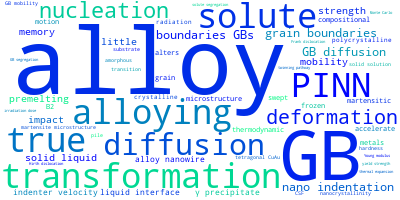

This panel presents information regarding the papers that have cited the interatomic potential (IP) whose page you are on. The OpenKIM machine learning based Deep Citation framework is used to determine whether the citing article actually used the IP in computations (denoted by "USED") or only provides it as a background citation (denoted by "NOT USED"). For more details on Deep Citation and how to work with this panel, click the documentation link at the top of the panel. The word cloud to the right is generated from the abstracts of IP principle source(s) (given below in "How to Cite") and the citing articles that were determined to have used the IP in order to provide users with a quick sense of the types of physical phenomena to which this IP is applied. The bar chart shows the number of articles that cited the IP per year. Each bar is divided into green (articles that USED the IP) and blue (articles that did NOT USE the IP). Users are encouraged to correct Deep Citation errors in determination by clicking the speech icon next to a citing article and providing updated information. This will be integrated into the next Deep Citation learning cycle, which occurs on a regular basis. OpenKIM acknowledges the support of the Allen Institute for AI through the Semantic Scholar project for providing citation information and full text of articles when available, which are used to train the Deep Citation ML algorithm. |

This panel provides information on past usage of this interatomic potential (IP) powered by the OpenKIM Deep Citation framework. The word cloud indicates typical applications of the potential. The bar chart shows citations per year of this IP (bars are divided into articles that used the IP (green) and those that did not (blue)). The complete list of articles that cited this IP is provided below along with the Deep Citation determination on usage. See the Deep Citation documentation for more information.

77 Citations (64 used)

Help us to determine which of the papers that cite this potential actually used it to perform calculations. If you know, click the .

USED (high confidence) R. K. Koju and Y. Mishin, “The Role of Grain Boundary Diffusion in the Solute Drag Effect,” Nanomaterials. 2021. link Times cited: 10 Abstract: Molecular dynamics (MD) simulations are applied to study sol… read more USED (high confidence) A. Bisht, R. K. Koju, Y. Qi, J. Hickman, Y. Mishin, and E. Rabkin, “The impact of alloying on defect-free nanoparticles exhibiting softer but tougher behavior,” Nature Communications. 2021. link Times cited: 12 USED (high confidence) Y.-S. Lin, G. P. P. Pun, and Y. Mishin, “Development of a physically-informed neural network interatomic potential for tantalum,” Computational Materials Science. 2021. link Times cited: 9 USED (high confidence) A. Bisht, R. K. Koju, Y. Qi, J. Hickman, Y. Mishin, and E. Rabkin, “Softer but tougher: The impact of alloying on defect-free nanoparticles.” 2021. link Times cited: 0 Abstract:

The classic paradigm of physical metallurgy is that the ad… read more USED (high confidence) G. P. P. Pun, V. Yamakov, J. Hickman, E. Glaessgen, and Y. Mishin, “Development of a general-purpose machine-learning interatomic potential for aluminum by the physically informed neural network method,” Physical Review Materials. 2020. link Times cited: 13 Abstract: Interatomic potentials constitute the key component of large… read more USED (high confidence) R. K. Koju and Y. Mishin, “Direct Atomistic Modeling of Solute Drag by Moving Grain Boundaries,” Mechanical Engineering eJournal. 2020. link Times cited: 23 Abstract: We show that molecular dynamics (MD) simulations are capable… read more USED (high confidence) R. K. Koju and Y. Mishin, “Relationship between grain boundary segregation and grain boundary diffusion in Cu-Ag alloys,” arXiv: Materials Science. 2020. link Times cited: 12 Abstract: While it is known that alloy components can segregate to gra… read more USED (high confidence) M. Diehl et al., “Solving Material Mechanics and Multiphysics Problems of Metals with Complex Microstructures Using DAMASK—The Düsseldorf Advanced Material Simulation Kit,” Advanced Engineering Materials. 2020. link Times cited: 13 Abstract: Predicting process–structure and structure–property relation… read more USED (high confidence) X. Lu, P. Yang, J. Luo, J. Ren, H. Xue, and Y. Ding, “Tensile mechanical performance of Ni–Co alloy nanowires by molecular dynamics simulation,” RSC Advances. 2019. link Times cited: 17 Abstract: In this present contribution, tensile mechanical properties … read more USED (high confidence) S. Madireddy et al., “Phase Segmentation in Atom-Probe Tomography Using Deep Learning-Based Edge Detection,” Scientific Reports. 2019. link Times cited: 16 USED (high confidence) E. Levo, F. Granberg, D. Utt, K. Albe, K. Nordlund, and F. Djurabekova, “Radiation stability of nanocrystalline single-phase multicomponent alloys,” Journal of Materials Research. 2019. link Times cited: 9 Abstract: In search of materials with better properties, polycrystalli… read more USED (high confidence) L. Huber, R. Hadian, B. Grabowski, and J. Neugebauer, “A machine learning approach to model solute grain boundary segregation,” npj Computational Materials. 2018. link Times cited: 83 USED (high confidence) S. Yuan, Z. Jiang, J. Liu, Y. Tang, and Y. Zhang, “Nano-twinning in a γ′ precipitate strengthened Ni-based superalloy,” Materials Research Letters. 2018. link Times cited: 19 Abstract: ABSTRACT Twinning has been found to be a dominate mechanism … read more USED (high confidence) K. V. Reddy and S. Pal, “Analysis of deformation behaviour of Al–Ni–Co thin film coated aluminium during nano-indentation: a molecular dynamics study,” Molecular Simulation. 2018. link Times cited: 16 Abstract: ABSTRACT In the present work, molecular dynamics simulations… read more USED (high confidence) R. K. Koju, K. Darling, K. Solanki, and Y. Mishin, “Atomistic modeling of capillary-driven grain boundary motion in Cu-Ta alloys,” Acta Materialia. 2018. link Times cited: 41 USED (high confidence) A. Zinovev, M. G. Bapanina, R. Babicheva, N. Enikeev, S. Dmitriev, and K. Zhou, “Deformation of nanocrystalline binary aluminum alloys with segregation of Mg, Co and Ti at grain boundaries,” Physics of Metals and Metallography. 2017. link Times cited: 6 USED (high confidence) S. Zhao, G. Velişa, H. Xue, H. Bei, W. J. Weber, and Y. Zhang, “Suppression of vacancy cluster growth in concentrated solid solution alloys,” Acta Materialia. 2017. link Times cited: 41 USED (high confidence) Y. Li, M. Lv, and H. Liang, “Local Structural Arrangement of Amorphous Al-Ni-Co Alloy during Uniaxial Tension: A Molecular Dynamics Study,” Materials Transactions. 2016. link Times cited: 2 Abstract: The local structural arrangement of the amorphous alloy syst… read more USED (high confidence) J. Hickman and Y. Mishin, “Disjoining potential and grain boundary premelting in binary alloys,” Physical Review B. 2016. link Times cited: 24 Abstract: Many grain boundaries (GBs) in crystalline materials develop… read more USED (high confidence) W. Nöhring and W. Curtin, “Thermodynamic properties of average-atom interatomic potentials for alloys,” Modelling and Simulation in Materials Science and Engineering. 2016. link Times cited: 17 Abstract: The atomistic mechanisms of deformation in multicomponent ra… read more USED (high confidence) T. Wallace et al., “Computational Modeling and Experimental Characterization of Martensitic Transformations in Nicoal for Self‐Sensing Materials.” 2015. link Times cited: 0 USED (low confidence) R. Liu, S. Li, L. Chen, J. Li, and L. Kong, “Investigation of Edge Dislocation Mobility in Ni-Co Solid Solutions by Molecular Dynamics Simulation,” Materials Today Communications. 2023. link Times cited: 0 USED (low confidence) A. Khoei, M. R. Seddighian, and A. R. Sameti, “Machine learning-based multiscale framework for mechanical behavior of nano-crystalline structures,” International Journal of Mechanical Sciences. 2023. link Times cited: 0 USED (low confidence) Y. Li and W. Qiang, “Compositional effects on the antiphase boundary energies in B2-type NiTi and NiTi-based high-entropy intermetallics,” Materials Chemistry and Physics. 2023. link Times cited: 0 USED (low confidence) M. Tahani, E. Postek, and T. Sadowski, “Investigating the Influence of Diffusion on the Cohesive Zone Model of the SiC/Al Composite Interface,” Molecules. 2023. link Times cited: 1 Abstract: Modeling metal matrix composites in finite element software … read more USED (low confidence) L. Jiao et al., “Atomistic insights into the synergistic effect of nanotwins and nano-precipitates on the mechanical behavior of superalloys,” Mechanics of Materials. 2023. link Times cited: 0 USED (low confidence) M. Wakeda, T. Osada, and T. Ohmura, “Atomistic analysis of temperature-dependent dislocation dynamics in Ni3Al-based intermetallic alloys,” Materials Today Communications. 2023. link Times cited: 2 USED (low confidence) Z. Ma and Z. Pan, “Efficient machine learning of solute segregation energy based on physics-informed features,” Scientific Reports. 2023. link Times cited: 0 USED (low confidence) Z. Zhang and C. Deng, “Solid solution softening in single crystalline metal nanowires studied by atomistic simulations,” Physical Review Materials. 2023. link Times cited: 0 USED (low confidence) Y.-F. Wu, W. Yu, and S. Shen, “Developing a variable charge potential for Hf/Nb/Ta/Ti/Zr/O system via machine learning global optimization,” Materials & Design. 2023. link Times cited: 1 USED (low confidence) X. Lu et al., “Strengthening mechanism of NiCoAl alloy induced by nanotwin under Hall-Petch effect,” International Journal of Mechanical Sciences. 2023. link Times cited: 1 USED (low confidence) G. Li, T. Yu, P. Wu, and M. Chen, “Molecular dynamics simulation of phase transformation and wear behavior of Ni35Al30Co35 high temperature shape memory alloy,” Wear. 2023. link Times cited: 0 USED (low confidence) N. Tuchinda and C. Schuh, “Triple junction solute segregation in Al-based polycrystals,” Physical Review Materials. 2023. link Times cited: 3 USED (low confidence) M. Tahani, E. Postek, L. Motevalizadeh, and T. Sadowski, “Effect of Vacancy Defect Content on the Interdiffusion of Cubic and Hexagonal SiC/Al Interfaces: A Molecular Dynamics Study,” Molecules. 2023. link Times cited: 5 Abstract: The mechanical properties of ceramic–metal nanocomposites ar… read more USED (low confidence) M. Tahani, E. Postek, and T. Sadowski, “Molecular Dynamics Study of Interdiffusion for Cubic and Hexagonal SiC/Al Interfaces,” Crystals. 2022. link Times cited: 5 Abstract: The mechanical properties of the SiC/Al interface are crucia… read more USED (low confidence) B. Waters, D. S. Karls, I. Nikiforov, R. Elliott, E. Tadmor, and B. Runnels, “Automated determination of grain boundary energy and potential-dependence using the OpenKIM framework,” Computational Materials Science. 2022. link Times cited: 5 USED (low confidence) J. Zhou, Y. Yang, and Y. Yu, “Revealing mechanical property–strengthening micro-mechanism of Ni/Ni3Al-based alloys by molecular dynamics simulation,” Journal of Molecular Modeling. 2022. link Times cited: 1 USED (low confidence) B. Xu et al., “Exploring the influence of percolation on vacancy-mediated diffusion in CoCrNi multi-principal element alloys,” Materials & Design. 2022. link Times cited: 4 USED (low confidence) F. Schwarz and R. Spolenak, “An MD-study on changing the elemental distribution and composition by alloying to control front propagation in Al–Ni multilayers,” Journal of Applied Physics. 2022. link Times cited: 3 Abstract: To cover the wide range of applications of reactive multilay… read more USED (low confidence) A.-V. Pham, T. Fang, V.-T. Nguyen, and T.-H. Chen, “Mechanical characteristics of Ni50Co50/Ni substrate during indentation by molecular dynamics,” Modelling and Simulation in Materials Science and Engineering. 2022. link Times cited: 2 Abstract: Coating an alloys film onto a metallic surface could dramati… read more USED (low confidence) T.-N. Vu, V.-T. Pham, V.-T. Nguyen, and T. Fang, “Interfacial strength and deformation mechanism of Ni/Co multilayers under uniaxial tension using molecular dynamics simulation,” Materials Today Communications. 2021. link Times cited: 9 USED (low confidence) R. Campos, S. Shinzato, A. Ishii, S. Nakamura, and S. Ogata, “Database-driven semigrand canonical Monte Carlo method: Application to segregation isotherm on defects in alloys.,” Physical review. E. 2021. link Times cited: 0 Abstract: The application of existing semigrand canonical ensemble Mon… read more USED (low confidence) Q. Gao et al., “Shear deformation mechanical performance of Ni–Co alloy nanoplate by molecular dynamics simulation,” Modern Physics Letters B. 2021. link Times cited: 3 Abstract: Ni–Co alloy has great advantages in the fields of micro-elec… read more USED (low confidence) Y.-C. Yang, C. Liu, C.-Y. Lin, and Z. Xia, “The effect of local atomic configuration in high-entropy alloys on the dislocation behaviors and mechanical properties,” Materials Science and Engineering A-structural Materials Properties Microstructure and Processing. 2021. link Times cited: 18 USED (low confidence) L.-F. Zhu, J. Janssen, S. Ishibashi, F. Körmann, B. Grabowski, and J. Neugebauer, “A fully automated approach to calculate the melting temperature of elemental crystals,” Computational Materials Science. 2021. link Times cited: 17 USED (low confidence) A. Atila, M. Kbirou, S. Ouaskit, and A. Hasnaoui, “On the presence of nanoscale heterogeneity in Al70Ni15Co15 metallic glass under pressure,” Journal of Non-crystalline Solids. 2020. link Times cited: 10 USED (low confidence) T.-X. Bui, T. Fang, and C.-I. Lee, “Effects of flaw shape and size on fracture toughness and destructive mechanism inside Ni15Al70Co15 metallic glass,” Computational Materials Science. 2020. link Times cited: 12 USED (low confidence) M. Ghaemi and R. Tavakoli, “Universal correlation between the thermodynamic potentials and some physical quantities of metallic glasses as a function of cooling rate during molecular dynamics simulation,” Journal of Non-crystalline Solids. 2020. link Times cited: 2 USED (low confidence) D. Choudhuri and A. CampBell, “Interface dominated deformation mechanisms in two-phase fcc/B2 nanostructures: Nishiyama-Wasserman vs. Kurdjumov-Sachs interfaces,” Computational Materials Science. 2020. link Times cited: 13 USED (low confidence) D. Choudhuri, S. G. Srinivasan, and R. Mishra, “Deformation of lamellar FCC-B2 nanostructures containing Kurdjumov-Sachs interfaces: Relation between interfacial structure and plasticity,” International Journal of Plasticity. 2020. link Times cited: 29 USED (low confidence) J. Mianroodi et al., “Atomistic phase field chemomechanical modeling of dislocation-solute-precipitate interaction in Ni–Al–Co,” Acta Materialia. 2019. link Times cited: 51 USED (low confidence) Y. Zhou, X. J. Han, and J. Li, “Transport properties and abnormal breakdown of the Stokes-Einstein relation in computer simulated Al72Ni16Co12 metallic melt,” Journal of Non-Crystalline Solids. 2019. link Times cited: 7 USED (low confidence) J. Fürnkranz, “Publication list,” Journal of Physics: Conference Series. 2019. link Times cited: 10 Abstract: PUBLICATION LIST of VICTOR MANUEL VILLANUEVA SANDOVAL availa… read more USED (low confidence) D. Choudhuri et al., “Enhancing strength and strain hardenability via deformation twinning in fcc-based high entropy alloys reinforced with intermetallic compounds,” Acta Materialia. 2019. link Times cited: 139 USED (low confidence) H. N. Pishkenari, F. S. Yousefi, and A. Taghibakhshi, “Determination of surface properties and elastic constants of FCC metals: a comparison among different EAM potentials in thin film and bulk scale,” Materials Research Express. 2018. link Times cited: 22 Abstract: Three independent elastic constants C11, C12, and C44 were c… read more USED (low confidence) M. Kbirou, S. Trady, A. Hasnaoui, and M. Mazroui, “Short and medium-range orders in Co3Al metallic glass,” Chemical Physics. 2018. link Times cited: 11 USED (low confidence) K. Choudhary, A. Biacchi, S. Ghosh, L. Hale, A. Walker, and F. Tavazza, “High-throughput assessment of vacancy formation and surface energies of materials using classical force-fields,” Journal of Physics: Condensed Matter. 2018. link Times cited: 16 Abstract: In this work, we present an open access database for surface… read more USED (low confidence) S. Zhao, Y. Zhang, and W. J. Weber, “Stability of vacancy-type defect clusters in Ni based on first-principles and molecular dynamics simulations☆,” Scripta Materialia. 2018. link Times cited: 10 USED (low confidence) M. Kbirou, M. Mazroui, and A. Hasnaoui, “Atomic packing and fractal behavior of Al-Co metallic glasses,” Journal of Alloys and Compounds. 2018. link Times cited: 17 USED (low confidence) R. Babicheva et al., “Effect of grain boundary segregation of Co or Ti on cyclic deformation of aluminium bi-crystals,” International Journal of Fatigue. 2017. link Times cited: 23 USED (low confidence) R. Babicheva et al., “Effect of grain boundary segregation on the deformation mechanisms and mechanical properties of nanocrystalline binary aluminum alloys,” Computational Materials Science. 2016. link Times cited: 49 USED (low confidence) R. K. Koju, K. Darling, L. Kecskes, and Y. Mishin, “Zener Pinning of Grain Boundaries and Structural Stability of Immiscible Alloys,” JOM. 2016. link Times cited: 51 USED (low confidence) S. Kalidindi, J. A. Gomberg, Z. Trautt, and C. Becker, “Application of data science tools to quantify and distinguish between structures and models in molecular dynamics datasets,” Nanotechnology. 2015. link Times cited: 39 Abstract: Structure quantification is key to successful mining and ext… read more USED (low confidence) L. Lilensten et al., “Segregation of Solutes at Dislocations: A New Alloy Design Parameter for Advanced Superalloys.” 2020. link Times cited: 7 NOT USED (high confidence) K. Choudhary, B. L. DeCost, L. Major, K. Butler, J. Thiyagalingam, and F. Tavazza, “Unified Graph Neural Network Force-field for the Periodic Table for Solids,” Digital Discovery. 2022. link Times cited: 6 Abstract: Classical force fields (FF) based on machine learning (ML) m… read more NOT USED (high confidence) O. Bindech, C. Goyhenex, and É. Gaudry, “A tight-binding atomistic approach for point defects and surfaces applied to the o-Al13Co4 quasicrystalline approximant,” Computational Materials Science. 2021. link Times cited: 0 NOT USED (high confidence) L. Xu, L. Casillas-Trujillo, Y. Gao, and H. Xu, “Compositional effects on stacking fault energies in Ni-based alloys using first-principles and atomistic simulations,” Computational Materials Science. 2021. link Times cited: 5 NOT USED (high confidence) D. Farkas and A. Caro, “Model interatomic potentials for Fe–Ni–Cr–Co–Al high-entropy alloys,” Journal of Materials Research. 2020. link Times cited: 76 Abstract: A set of embedded atom model (EAM) interatomic potentials wa… read more NOT USED (high confidence) L. Karkina, I. Karkin, A. Kuznetsov, and Y. Gornostyrev, “Alloying Element Segregation and Grain Boundary Reconstruction, Atomistic Modeling.” 2019. link Times cited: 8 Abstract: Grain boundary (GB) segregation is an important phenomenon t… read more NOT USED (high confidence) S. Mahmoud and N. Mousseau, “Long-time point defect diffusion in ordered nickel-based binary alloys: How small kinetic differences can lead to completely long-time structural evolution,” Materialia. 2018. link Times cited: 15 NOT USED (high confidence) Y. Hu and T. Rupert, “Atomistic modeling of interfacial segregation and structural transitions in ternary alloys,” Journal of Materials Science. 2018. link Times cited: 19 NOT USED (high confidence) L. Hale, “Comparing Modeling Predictions of Aluminum Edge Dislocations: Semidiscrete Variational Peierls–Nabarro Versus Atomistics,” JOM. 2018. link Times cited: 7 NOT USED (high confidence) P. Chowdhury, “Frontiers of Theoretical Research on Shape Memory Alloys: A General Overview,” Shape Memory and Superelasticity. 2018. link Times cited: 16 NOT USED (high confidence) P. Chowdhury and H. Sehitoglu, “Deformation physics of shape memory alloys – Fundamentals at atomistic frontier,” Progress in Materials Science. 2017. link Times cited: 110 NOT USED (high confidence) Y. Zhang et al., “Influence of chemical disorder on energy dissipation and defect evolution in advanced alloys,” Journal of Materials Research. 2016. link Times cited: 103 Abstract: Historically, alloy development with better radiation perfor… read more NOT USED (high confidence) S. M. Rassoulinejad-Mousavi, Y. Mao, and Y. Zhang, “Evaluation of Copper, Aluminum and Nickel Interatomic Potentials on Predicting the Elastic Properties,” arXiv: Computational Physics. 2016. link Times cited: 63 Abstract: Choice of appropriate force field is one of the main concern… read more |

| Funding | Not available |

| Short KIM ID

The unique KIM identifier code.

| MO_826591359508_000 |

| Extended KIM ID

The long form of the KIM ID including a human readable prefix (100 characters max), two underscores, and the Short KIM ID. Extended KIM IDs can only contain alpha-numeric characters (letters and digits) and underscores and must begin with a letter.

| EAM_Dynamo_PunYamakovMishin_2013_NiAlCo__MO_826591359508_000 |

| DOI |

10.25950/48e9959e https://doi.org/10.25950/48e9959e https://commons.datacite.org/doi.org/10.25950/48e9959e |

| KIM Item Type

Specifies whether this is a Portable Model (software implementation of an interatomic model); Portable Model with parameter file (parameter file to be read in by a Model Driver); Model Driver (software implementation of an interatomic model that reads in parameters).

| Portable Model using Model Driver EAM_Dynamo__MD_120291908751_005 |

| Driver | EAM_Dynamo__MD_120291908751_005 |

| KIM API Version | 2.0 |

| Potential Type | eam |

| Grade | Name | Category | Brief Description | Full Results | Aux File(s) |

|---|---|---|---|---|---|

| P | vc-species-supported-as-stated | mandatory | The model supports all species it claims to support; see full description. |

Results | Files |

| P | vc-periodicity-support | mandatory | Periodic boundary conditions are handled correctly; see full description. |

Results | Files |

| P | vc-permutation-symmetry | mandatory | Total energy and forces are unchanged when swapping atoms of the same species; see full description. |

Results | Files |

| A | vc-forces-numerical-derivative | consistency | Forces computed by the model agree with numerical derivatives of the energy; see full description. |

Results | Files |

| F | vc-dimer-continuity-c1 | informational | The energy versus separation relation of a pair of atoms is C1 continuous (i.e. the function and its first derivative are continuous); see full description. |

Results | Files |

| P | vc-objectivity | informational | Total energy is unchanged and forces transform correctly under rigid-body translation and rotation; see full description. |

Results | Files |

| P | vc-inversion-symmetry | informational | Total energy is unchanged and forces change sign when inverting a configuration through the origin; see full description. |

Results | Files |

| P | vc-memory-leak | informational | The model code does not have memory leaks (i.e. it releases all allocated memory at the end); see full description. |

Results | Files |

| P | vc-thread-safe | mandatory | The model returns the same energy and forces when computed in serial and when using parallel threads for a set of configurations. Note that this is not a guarantee of thread safety; see full description. |

Results | Files |

| P | vc-unit-conversion | mandatory | The model is able to correctly convert its energy and/or forces to different unit sets; see full description. |

Results | Files |

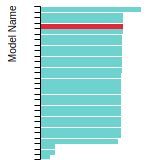

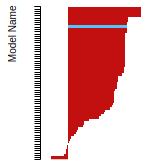

BCC Lattice Constant

This bar chart plot shows the mono-atomic body-centered cubic (bcc) lattice constant predicted by the current model (shown in the unique color) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

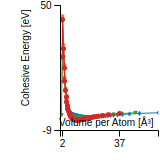

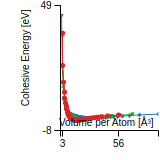

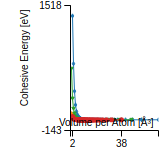

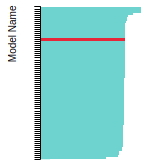

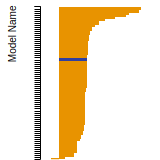

Cohesive Energy Graph

This graph shows the cohesive energy versus volume-per-atom for the current mode for four mono-atomic cubic phases (body-centered cubic (bcc), face-centered cubic (fcc), simple cubic (sc), and diamond). The curve with the lowest minimum is the ground state of the crystal if stable. (The crystal structure is enforced in these calculations, so the phase may not be stable.) Graphs are generated for each species supported by the model.

Diamond Lattice Constant

This bar chart plot shows the mono-atomic face-centered diamond lattice constant predicted by the current model (shown in the unique color) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

Dislocation Core Energies

This graph shows the dislocation core energy of a cubic crystal at zero temperature and pressure for a specific set of dislocation core cutoff radii. After obtaining the total energy of the system from conjugate gradient minimizations, non-singular, isotropic and anisotropic elasticity are applied to obtain the dislocation core energy for each of these supercells with different dipole distances. Graphs are generated for each species supported by the model.

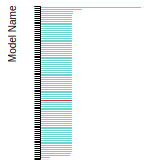

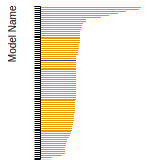

(No matching species)FCC Elastic Constants

This bar chart plot shows the mono-atomic face-centered cubic (fcc) elastic constants predicted by the current model (shown in blue) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

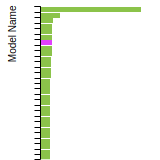

FCC Lattice Constant

This bar chart plot shows the mono-atomic face-centered cubic (fcc) lattice constant predicted by the current model (shown in red) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

FCC Stacking Fault Energies

This bar chart plot shows the intrinsic and extrinsic stacking fault energies as well as the unstable stacking and unstable twinning energies for face-centered cubic (fcc) predicted by the current model (shown in blue) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

FCC Surface Energies

This bar chart plot shows the mono-atomic face-centered cubic (fcc) relaxed surface energies predicted by the current model (shown in blue) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

SC Lattice Constant

This bar chart plot shows the mono-atomic simple cubic (sc) lattice constant predicted by the current model (shown in the unique color) compared with the predictions for all other models in the OpenKIM Repository that support the species. The vertical bars show the average and standard deviation (one sigma) bounds for all model predictions. Graphs are generated for each species supported by the model.

Cubic Crystal Basic Properties Table

Species: AlSpecies: Co

Species: Ni

Creators:

Contributor: karls

Publication Year: 2019

DOI: https://doi.org/10.25950/64cb38c5

This Test Driver uses LAMMPS to compute the cohesive energy of a given monoatomic cubic lattice (fcc, bcc, sc, or diamond) at a variety of lattice spacings. The lattice spacings range from a_min (=a_min_frac*a_0) to a_max (=a_max_frac*a_0) where a_0, a_min_frac, and a_max_frac are read from stdin (a_0 is typically approximately equal to the equilibrium lattice constant). The precise scaling and number of lattice spacings sampled between a_min and a_0 (a_0 and a_max) is specified by two additional parameters passed from stdin: N_lower and samplespacing_lower (N_upper and samplespacing_upper). Please see README.txt for further details.

Creators:

Contributor: ilia

Publication Year: 2024

DOI: https://doi.org/10.25950/888f9943

Computes the elastic constants for an arbitrary crystal. A robust computational protocol is used, attempting multiple methods and step sizes to achieve an acceptably low error in numerical differentiation and deviation from material symmetry. The crystal structure is specified using the AFLOW prototype designation as part of the Crystal Genome testing framework. In addition, the distance from the obtained elasticity tensor to the nearest isotropic tensor is computed.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Elastic constants for AlNi in AFLOW crystal prototype A3B2_hP5_164_ad_d at zero temperature and pressure v000 | view | 164781 |

Creators: Junhao Li and Ellad Tadmor

Contributor: tadmor

Publication Year: 2019

DOI: https://doi.org/10.25950/5853fb8f

Computes the cubic elastic constants for some common crystal types (fcc, bcc, sc, diamond) by calculating the hessian of the energy density with respect to strain. An estimate of the error associated with the numerical differentiation performed is reported.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Elastic constants for bcc Al at zero temperature v006 | view | 6366 | |

| Elastic constants for bcc Co at zero temperature v006 | view | 2463 | |

| Elastic constants for bcc Ni at zero temperature v006 | view | 1887 | |

| Elastic constants for diamond Co at zero temperature v001 | view | 7613 | |

| Elastic constants for fcc Al at zero temperature v006 | view | 2303 | |

| Elastic constants for fcc Co at zero temperature v006 | view | 2047 | |

| Elastic constants for fcc Ni at zero temperature v006 | view | 2271 | |

| Elastic constants for sc Al at zero temperature v006 | view | 1791 | |

| Elastic constants for sc Co at zero temperature v006 | view | 4382 | |

| Elastic constants for sc Ni at zero temperature v006 | view | 4510 |

Creators: Junhao Li

Contributor: jl2922

Publication Year: 2019

DOI: https://doi.org/10.25950/d794c746

Computes the elastic constants for hcp crystals by calculating the hessian of the energy density with respect to strain. An estimate of the error associated with the numerical differentiation performed is reported.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Elastic constants for hcp Al at zero temperature v004 | view | 1974 | |

| Elastic constants for hcp Co at zero temperature v004 | view | 1878 | |

| Elastic constants for hcp Ni at zero temperature v004 | view | 2101 |

Creators:

Contributor: ilia

Publication Year: 2024

DOI: https://doi.org/10.25950/2f2c4ad3

Computes the equilibrium crystal structure and energy for an arbitrary crystal at zero temperature and applied stress by performing symmetry-constrained relaxation. The crystal structure is specified using the AFLOW prototype designation. Multiple sets of free parameters corresponding to the crystal prototype may be specified as initial guesses for structure optimization. No guarantee is made regarding the stability of computed equilibria, nor that any are the ground state.

Creators:

Contributor: brunnels

Publication Year: 2022

DOI: https://doi.org/10.25950/2c59c9d6

Computes grain boundary energy for a range of tilt angles given a crystal structure, tilt axis, and material.

Creators: Daniel S. Karls and Junhao Li

Contributor: karls

Publication Year: 2019

DOI: https://doi.org/10.25950/2765e3bf

Equilibrium lattice constant and cohesive energy of a cubic lattice at zero temperature and pressure.

Creators: Daniel S. Karls and Junhao Li

Contributor: karls

Publication Year: 2019

DOI: https://doi.org/10.25950/c339ca32

Calculates lattice constant of hexagonal bulk structures at zero temperature and pressure by using simplex minimization to minimize the potential energy.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Equilibrium lattice constants for hcp Al v005 | view | 23527 | |

| Equilibrium lattice constants for hcp Co v005 | view | 33205 | |

| Equilibrium lattice constants for hcp Ni v005 | view | 30308 |

Creators:

Contributor: mjwen

Publication Year: 2024

DOI: https://doi.org/10.25950/9d9822ec

This Test Driver uses LAMMPS to compute the linear thermal expansion coefficient at a finite temperature under a given pressure for a cubic lattice (fcc, bcc, sc, diamond) of a single given species.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Linear thermal expansion coefficient of fcc Al at 293.15 K under a pressure of 0 MPa v002 | view | 508743 | |

| Linear thermal expansion coefficient of fcc Ni at 293.15 K under a pressure of 0 MPa v002 | view | 976292 |

Creators: Matt Bierbaum

Contributor: mattbierbaum

Publication Year: 2019

DOI: https://doi.org/10.25950/64f4999b

Calculates the phonon dispersion relations for fcc lattices and records the results as curves.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Phonon dispersion relations for fcc Al v004 | view | 55277 | |

| Phonon dispersion relations for fcc Ni v004 | view | 49487 |

Creators:

Contributor: SubrahmanyamPattamatta

Publication Year: 2019

DOI: https://doi.org/10.25950/b4cfaf9a

Intrinsic and extrinsic stacking fault energies, unstable stacking fault energy, unstable twinning energy, stacking fault energy as a function of fractional displacement, and gamma surface for a monoatomic FCC lattice at zero temperature and pressure.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Stacking and twinning fault energies for fcc Al v002 | view | 7291285 | |

| Stacking and twinning fault energies for fcc Ni v002 | view | 7908417 |

Creators: Matt Bierbaum

Contributor: mattbierbaum

Publication Year: 2019

DOI: https://doi.org/10.25950/6c43a4e6

Calculates the surface energy of several high symmetry surfaces and produces a broken-bond model fit. In latex form, the fit equations are given by:

E_{FCC} (\vec{n}) = p_1 (4 \left( |x+y| + |x-y| + |x+z| + |x-z| + |z+y| +|z-y|\right)) + p_2 (8 \left( |x| + |y| + |z|\right)) + p_3 (2 ( |x+ 2y + z| + |x+2y-z| + |x-2y + z| + |x-2y-z| + |2x+y+z| + |2x+y-z| +|2x-y+z| +|2x-y-z| +|x+y+2z| +|x+y-2z| +|x-y+2z| +|x-y-2z| ) + c

E_{BCC} (\vec{n}) = p_1 (6 \left( | x+y+z| + |x+y-z| + |-x+y-z| + |x-y+z| \right)) + p_2 (8 \left( |x| + |y| + |z|\right)) + p_3 (4 \left( |x+y| + |x-y| + |x+z| + |x-z| + |z+y| +|z-y|\right)) +c.

In Python, these two fits take the following form:

def BrokenBondFCC(params, index):

import numpy

x, y, z = index

x = x / numpy.sqrt(x**2.+y**2.+z**2.)

y = y / numpy.sqrt(x**2.+y**2.+z**2.)

z = z / numpy.sqrt(x**2.+y**2.+z**2.)

return params[0]*4* (abs(x+y) + abs(x-y) + abs(x+z) + abs(x-z) + abs(z+y) + abs(z-y)) + params[1]*8*(abs(x) + abs(y) + abs(z)) + params[2]*(abs(x+2*y+z) + abs(x+2*y-z) +abs(x-2*y+z) +abs(x-2*y-z) + abs(2*x+y+z) +abs(2*x+y-z) +abs(2*x-y+z) +abs(2*x-y-z) + abs(x+y+2*z) +abs(x+y-2*z) +abs(x-y+2*z) +abs(x-y-2*z))+params[3]

def BrokenBondBCC(params, x, y, z):

import numpy

x, y, z = index

x = x / numpy.sqrt(x**2.+y**2.+z**2.)

y = y / numpy.sqrt(x**2.+y**2.+z**2.)

z = z / numpy.sqrt(x**2.+y**2.+z**2.)

return params[0]*6*(abs(x+y+z) + abs(x-y-z) + abs(x-y+z) + abs(x+y-z)) + params[1]*8*(abs(x) + abs(y) + abs(z)) + params[2]*4* (abs(x+y) + abs(x-y) + abs(x+z) + abs(x-z) + abs(z+y) + abs(z-y)) + params[3]

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Broken-bond fit of high-symmetry surface energies in fcc Al v004 | view | 27127 | |

| Broken-bond fit of high-symmetry surface energies in fcc Ni v004 | view | 35764 |

Creators:

Contributor: efuem

Publication Year: 2023

DOI: https://doi.org/10.25950/fca89cea

Computes the monovacancy formation energy and relaxation volume for cubic and hcp monoatomic crystals.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Monovacancy formation energy and relaxation volume for fcc Al | view | 405723 | |

| Monovacancy formation energy and relaxation volume for fcc Ni | view | 532129 | |

| Monovacancy formation energy and relaxation volume for hcp Co | view | 475147 |

Creators:

Contributor: efuem

Publication Year: 2023

DOI: https://doi.org/10.25950/c27ba3cd

Computes the monovacancy formation and migration energies for cubic and hcp monoatomic crystals.

| Test | Test Results | Link to Test Results page | Benchmark time

Usertime multiplied by the Whetstone Benchmark. This number can be used (approximately) to compare the performance of different models independently of the architecture on which the test was run.

Measured in Millions of Whetstone Instructions (MWI) |

|---|---|---|---|

| Vacancy formation and migration energy for fcc Al | view | 1097093 | |

| Vacancy formation and migration energy for fcc Ni | view | 1494349 | |

| Vacancy formation and migration energy for hcp Co | view | 3594521 |

| Test | Error Categories | Link to Error page |

|---|---|---|

| Elastic constants for diamond Al at zero temperature v001 | other | view |

| Elastic constants for diamond Ni at zero temperature v001 | other | view |

EquilibriumCrystalStructure__TD_457028483760_000

| Test | Error Categories | Link to Error page |

|---|---|---|

| Equilibrium crystal structure and energy for AlNi in AFLOW crystal prototype A4B3_cI112_230_af_g v000 | other | view |

| Equilibrium crystal structure and energy for AlCo in AFLOW crystal prototype A9B2_mP22_14_a4e_e v000 | other | view |

EquilibriumCrystalStructure__TD_457028483760_002

LatticeConstantCubicEnergy__TD_475411767977_006

| Test | Error Categories | Link to Error page |

|---|---|---|

| Equilibrium zero-temperature lattice constant for diamond Al | other | view |

| Equilibrium zero-temperature lattice constant for diamond Co | other | view |

No Driver

| Verification Check | Error Categories | Link to Error page |

|---|---|---|

| DimerContinuityC1__VC_303890932454_005 | other | view |

| MemoryLeak__VC_561022993723_004 | other | view |

| EAM_Dynamo_PunYamakovMishin_2013_NiAlCo__MO_826591359508_000.txz | Tar+XZ | Linux and OS X archive |

| EAM_Dynamo_PunYamakovMishin_2013_NiAlCo__MO_826591359508_000.zip | Zip | Windows archive |

This Model requires a Model Driver. Archives for the Model Driver EAM_Dynamo__MD_120291908751_005 appear below.

| EAM_Dynamo__MD_120291908751_005.txz | Tar+XZ | Linux and OS X archive |

| EAM_Dynamo__MD_120291908751_005.zip | Zip | Windows archive |