Citations

This panel presents information regarding the papers that have cited the interatomic potential (IP) whose page you are on.

The OpenKIM machine learning based Deep Citation framework is used to determine whether the citing article actually used the IP in computations (denoted by "USED") or only provides it as a background citation (denoted by "NOT USED"). For more details on Deep Citation and how to work with this panel, click the documentation link at the top of the panel.

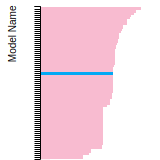

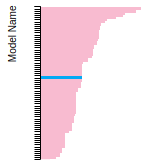

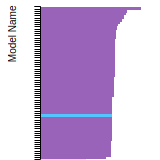

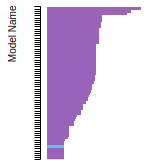

The word cloud to the right is generated from the abstracts of IP principle source(s) (given below in "How to Cite") and the citing articles that were determined to have used the IP in order to provide users with a quick sense of the types of physical phenomena to which this IP is applied.

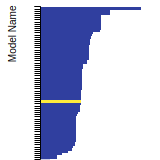

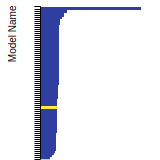

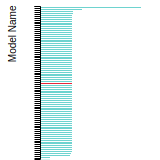

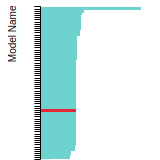

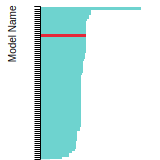

The bar chart shows the number of articles that cited the IP per year. Each bar is divided into green (articles that USED the IP) and blue (articles that did NOT USE the IP).

Users are encouraged to correct Deep Citation errors in determination by clicking the speech icon next to a citing article and providing updated information. This will be integrated into the next Deep Citation learning cycle, which occurs on a regular basis.

OpenKIM acknowledges the support of the Allen Institute for AI through the Semantic Scholar project for providing citation information and full text of articles when available, which are used to train the Deep Citation ML algorithm.

|

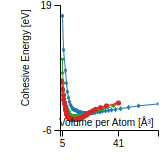

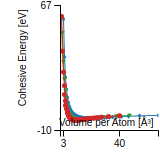

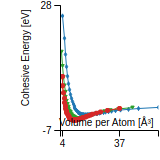

This panel provides information on past usage of this interatomic potential (IP) powered by the OpenKIM Deep Citation framework. The word cloud indicates typical applications of the potential. The bar chart shows citations per year of this IP (bars are divided into articles that used the IP (green) and those that did not (blue)). The complete list of articles that cited this IP is provided below along with the Deep Citation determination on usage. See the Deep Citation documentation for more information.

Help us to determine which of the papers that cite this potential actually used it to perform calculations. If you know, click the .

USED (definite) M. Munaji, G. A. Buntoro, A. Purniawan, and R. Arifin, “Molecular Dynamics Simulations of Iron-Joining Using Copper as a Filler Metal,” Makara Journal of Science. 2018. link Times cited: 2 Abstract: The study of the liquid filler metal infiltration on the nar… read moreAbstract: The study of the liquid filler metal infiltration on the narrow channel of adjoining metal bears importance in understanding the mechanism of the metal brazing process. In this study, we employed the molecular dynamics simulation to understand the mechanism of Cu liquid infiltration through the narrow channel of Fe slabs. Our simulation showed that the wetting process of Fe surfaces by Cu liquid precedes the infiltration process. This study also revealed that the channel became narrower and blockages were found in the channel due to the deformation of Fe surface. In addition to the effect of viscous drag, this process should also contribute to the decreasing speed of the Cu liquid front. read less USED (definite) Y. Cheng, W. Cui, L. Wang, C. Peng, S. Wang, and Y.-yang Wang, “Vitrification and Crystallization of Phase-Separated Metallic Liquid.” 2017. link Times cited: 5 Abstract: The liquid–liquid phase separation (LLPS) behavior of Fe50Cu… read moreAbstract: The liquid–liquid phase separation (LLPS) behavior of Fe50Cu50 melt from 3500 K to 300 K with different rapid quenching is investigated by molecular dynamics (MD) simulation based on the embedded atom method (EAM). The liquid undergoes metastable phase separation by spinodal decomposition in the undercooled regime and subsequently solidifies into three different Fe-rich microstructures: the interconnected-type structure is kept in the glass and crystal at a higher cooling rate, while the Fe-rich droplets are found to crystalize at a lower cooling rate. During the crystallization process, only Fe-rich clusters can act as the solid nuclei. The twinning planes can be observed in the crystal and only the homogeneous atomic stacking shows mirror symmetry along the twinning boundary. Our present work provides atomic-scale understanding of LLPS melt during the cooling process. read less USED (definite) S. Shao and J. Wang, “Relaxation Mechanisms, Structure and Properties of Semi-Coherent Interfaces.” 2015. link Times cited: 10 Abstract: In this work, using the Cu–Ni (111) semi-coherent interface … read moreAbstract: In this work, using the Cu–Ni (111) semi-coherent interface as a model system, we combine atomistic simulations and defect theory to reveal the relaxation mechanisms, structure, and properties of semi-coherent interfaces. By calculating the generalized stacking fault energy (GSFE) profile of the interface, two stable structures and a high-energy structure are located. During the relaxation, the regions that possess the stable structures expand and develop into coherent regions; the regions with high-energy structure shrink into the intersection of misfit dislocations (nodes). This process reduces the interface excess potential energy but increases the core energy of the misfit dislocations and nodes. The core width is dependent on the GSFE of the interface. The high-energy structure relaxes by relative rotation and dilatation between the crystals. The relative rotation is responsible for the spiral pattern at nodes. The relative dilatation is responsible for the creation of free volume at nodes, which facilitates the nodes’ structural transformation. Several node structures have been observed and analyzed. The various structures have significant impact on the plastic deformation in terms of lattice dislocation nucleation, as well as the point defect formation energies. read less USED (high confidence) B. Waters, D. S. Karls, I. Nikiforov, R. Elliott, E. Tadmor, and B. Runnels, “Automated determination of grain boundary energy and potential-dependence using the OpenKIM framework,” Computational Materials Science. 2022. link Times cited: 5 USED (high confidence) W. Guo, C. Wu, X. Meng, C. Luo, and Z. Lin, “Molecular dynamics simulation-based microstructure evolution and subsurface damage of Fe-Ni alloy grinding,” Journal of Intelligent Manufacturing and Special Equipment. 2022. link Times cited: 0 Abstract: PurposeMolecular dynamics is an emerging simulation techniqu… read moreAbstract: PurposeMolecular dynamics is an emerging simulation technique in the field of machining in recent years. Many researchers have tried to simulate different processing methods of various materials with the theory of molecular dynamics (MD), and some preliminary conclusions have been obtained. However, the application of MD simulation is more limited compared with traditional finite element model (FEM) simulation technique due to the complex modeling approach and long computation time. Therefore, more studies on the MD simulations are required to provide a reliable theoretical basis for the nanoscale interpretation of grinding process. This study investigates the crystal structures, dislocations, force, temperature and subsurface damage (SSD) in the grinding of iron-nickel alloy using MD analysis.Design/methodology/approach In this study the simulation model is established on the basis of the workpiece and single cubic boron nitride (CBN) grit with embedded atom method and Morse potentials describing the forces and energies between different atoms. The effects of grinding parameters on the material microstructure are studied based on the simulation results.FindingsWhen CBN grit goes through one of the grains, the arrangement of atoms within the grain will be disordered, but other grains will not be easily deformed due to the protection of the grain boundaries. Higher grinding speed and larger cutting depth can cause greater impact of grit on the atoms, and more body-centered cubic (BCC) structures will be destroyed. The dislocations will appear in grain boundaries due to the rearrangement of atoms in grinding. The increase of grinding speed results in the more transformation from BCC to amorphous structures.Originality/valueThis study is aimed to study the grinding of Fe-Ni alloy (maraging steel) with single grit through MD simulation method, and to reveal the microstructure evolution within the affected range of SSD layer in the workpiece. The simulation model of polycrystalline structure of Fe-Ni maraging steel and grinding process of single CBN grit is constructed based on the Voronoi algorithm. The atomic accumulation, transformation of crystal structures, evolution of dislocations as well as the generation of SSD are discussed according to the simulation results. read less USED (high confidence) M. Fokt, G. Adjanor, and T. Jourdan, “A variable-gap model for helium bubbles in nickel,” Computational Materials Science. 2022. link Times cited: 1 USED (high confidence) S. Mori, N. Matsuda, T. Okita, M. Aichi, M. Itakura, and K. Suzuki, “Modeling Changes in the Second Harmonic Generation of Ultrasonic Waves Having Wavelengths Beyond the Length Scale of Conventional Molecular Dynamics,” MatSciRN: Other Electronic. 2022. link Times cited: 3 Abstract: The nonlinear ultrasonic (NLU) technique is attracting atten… read moreAbstract: The nonlinear ultrasonic (NLU) technique is attracting attention as a nondestructive method for the detection of nanostructures in crystalline materials. In this study, we developed a method to quantify the changes in NLU signals associated with nanostructures formation using molecular dynamics (MD) simulations. To achieve this, we used a nonreflective boundary, which reduces the computational cost to the first power of the wavelength; this is distinct from previous proposals using conventional MD method, for which the computational cost is proportional to the square of the wavelength. The nonreflective boundary eliminates the influence of reflected waves at the detection position by setting a buffer region at the end of the simulated cell opposite from the wave source, and the displacements and velocities of all atoms in this region are periodically reset. Using this method, we succeeded in speeding up the calculation by up to 4000 times while maintaining similar accuracy to that of the conventional MD method. Thus, it is possible to extend the NLU wavelength by approximately four orders of magnitude, which approaches the wavelengths used in actual inspections and, thus, simulate the changes in the NLU signals induced by nanostructures by MD. Consequently, this method will contribute to the development of a robust inspection technique based on scientific principles. read less USED (high confidence) L. Xu, L. Casillas-Trujillo, Y. Gao, and H. Xu, “Compositional effects on stacking fault energies in Ni-based alloys using first-principles and atomistic simulations,” Computational Materials Science. 2021. link Times cited: 5 USED (high confidence) H. Zhang, Y.-li Chen, X. Wang, H. Li, and Y. Li, “Molecular Dynamics Research on the Impact of Vacancies on Cu Precipitation in BCC-Fe,” Materials. 2021. link Times cited: 0 Abstract: The molecular dynamics (MD) simulation method was used to ex… read moreAbstract: The molecular dynamics (MD) simulation method was used to explore the impact of vacancy concentration (0 at%, 0.1 at% and 0.2 at%) on the diffusion and precipitation rate of Cu atoms in the Fe-3.5Cu alloy and the growth of Cu precipitation during the aging process of the alloy. The mechanism of the influence of Cu precipitation relative to the tensile properties of Fe-3.5Cu alloy was investigated. The results showed that the presence of vacancies will promote the diffusion and precipitation of Cu atoms in the Fe-3.5Cu alloy, but the diffusion and precipitation rate of Cu atoms does not always increase with the increase in vacancies. In the alloy containing 0.2 at% vacancies, the diffusion and precipitation rate of Cu atoms is lower than that in the alloy containing 0.1 at% vacancies. During the aging process, when the alloy contains no vacancies, no Cu precipitates will be produced. In the alloy containing 0.1 at% vacancies, the size of the Cu precipitates produced is larger than the size of the Cu precipitates produced in the alloy containing 0.2 at% vacancies, but the number of precipitates is less than that in the alloy with 0.2 at% vacancies. During the tensile process, the Cu precipitates will promote early occurrence of phase transition of the internal crystal structure in the Fe-3.5Cu alloy system, and lead to the generation of vacancy defects in the system, thus weakening the yield strength and strain hardening strength of the alloy. read less USED (high confidence) S. Dong, X.-Y. Liu, and C. Zhou, “Atomistic modeling of plastic deformation in B2-FeAl/Al nanolayered composites,” Journal of Materials Science. 2021. link Times cited: 0 USED (high confidence) S. Eder, P. Grützmacher, M. R. Ripoll, and J. Belak, “Elucidating the Onset of Plasticity in Sliding Contacts Using Differential Computational Orientation Tomography,” Tribology Letters. 2021. link Times cited: 9 USED (high confidence) X. Xu, P. Binkele, W. Verestek, and S. Schmauder, “Molecular Dynamics Simulation of High-Temperature Creep Behavior of Nickel Polycrystalline Nanopillars,” Molecules. 2021. link Times cited: 0 Abstract: As Nickel (Ni) is the base of important Ni-based superalloys… read moreAbstract: As Nickel (Ni) is the base of important Ni-based superalloys for high-temperature applications, it is important to determine the creep behavior of its nano-polycrystals. The nano-tensile properties and creep behavior of nickel polycrystalline nanopillars are investigated employing molecular dynamics simulations under different temperatures, stresses, and grain sizes. The mechanisms behind the creep behavior are analyzed in detail by calculating the stress exponents, grain boundary exponents, and activation energies. The novel results in this work are summarized in a deformation mechanism map and are in good agreement with Ashby’s experimental results for pure Ni. Through the deformation diagram, dislocation creep dominates the creep process when applying a high stress, while grain boundary sliding prevails at lower stress levels. These two mechanisms could also be coupled together for a low-stress but a high-temperature creep simulation. In this work, the dislocation creep is clearly observed and discussed in detail. Through analyzing the activation energies, vacancy diffusion begins to play an important role in enhancing the grain boundary creep in the creep process when the temperature is above 1000 K. read less USED (high confidence) K. Kanamori, S. Toriumi, Y. Kimoto, and A. Yonezu, “Repeated Laser Shock-Wave Adhesion Test for Metallic Coatings: Adhesion Durability and Its Mechanism Studied by Molecular Dynamics Simulation,” Coatings. 2021. link Times cited: 2 Abstract: We evaluated the adhesion of polycrystalline metallic coatin… read moreAbstract: We evaluated the adhesion of polycrystalline metallic coatings using the laser shock-wave adhesion test (LaSAT). This study used Cu plating on stainless steel as a coating model. The adhesion strength and toughness were successfully estimated using LaSAT and finite element method with cohesive zone model. Next, repeated LaSAT was conducted to apply cyclic loading to evaluate adhesion fatigue life, i.e., the number of loading cycles required for delamination. Furthermore, this study performed molecular dynamics (MD) simulations to elucidate the adhesion mechanism for the Cu/Fe interface. To verify our model, the interfacial fracture toughness was computed using the MD simulation and compared with the results of LaSAT. Next, cyclic loading was applied to the MD model to investigate crack initiation around the interface. We found that dislocations are generated from the internal grain and are accumulated at grain boundaries. This accumulation results in fatigue crack initiation due to stress concentration. read less USED (high confidence) K. Chen et al., “Molecular Dynamics Simulations of High-speed Nanoscale Sliding with Third Medium,” IOP Conference Series: Earth and Environmental Science. 2021. link Times cited: 0 Abstract: 3D non-equilibrium molecular dynamics simulations are perfor… read moreAbstract: 3D non-equilibrium molecular dynamics simulations are performed to investigate the friction characteristic of Fe-Fe tribopair system under third medium condition. A Fe-Fe sliding simulation model with the soft third medium (Cu nanoparticle) is built. The Friction force, evolution of the structure of interface and the temperature profiles of the sliding system are obtained. The influence of the sliding velocity to the temperature and structure change under third medium is investigated. The influence of Cu nanoparticle to the microstructure evolution and change of the friction characteristic is extremely concerned. The results show that the Cu nanoparticle can decrease the friction force and average temperature under the relatively low velocity (25m/s). However, under high velocity (150m/s), the positive effect is not obvious. A Cu nano-film would form on the surface, which is useful for weakening the destruction of the interface, and protecting the sliding blocks. Under high velocity, a mixing layer would be formed in both two cases (with or without Cu nanoparticle). read less USED (high confidence) W. Nöhring, J.-C. Griesser, P. Dondl, and L. Pastewka, “Surface lattice Green’s functions for high-entropy alloys,” Modelling and Simulation in Materials Science and Engineering. 2021. link Times cited: 0 Abstract: We study the surface elastic response of pure Ni, the random… read moreAbstract: We study the surface elastic response of pure Ni, the random alloy FeNiCr and an average FeNiCr alloy in terms of the surface lattice Green’s function. We propose a scheme for computing per-site Green’s function and study their per-site variations. The average FeNiCr alloys accurately reproduces the mean Green’s function of the full random alloy. Variation around this mean is largest near the edge of the surface Brillouin-zone and decays as q −2 with wavevector q towards the Γ-point. We also present expressions for the continuum surface Green’s function of anisotropic solids of finite and infinite thickness and show that the atomistic Green’s function approaches continuum near the Γ-point. Our results are a first step towards efficient contact calculations and Peierls–Nabarro type models for dislocations in high-entropy alloys. read less USED (high confidence) H. Zhang, X. Wang, L. Huirong, C. Li, and L. Yungang, “Molecular Dynamics Study on the Impact of Cu Clusters at the BCC-Fe Grain Boundary on the Tensile Properties of Crystal,” Metals. 2020. link Times cited: 3 Abstract: The molecular dynamics (MD) method was used to simulate and … read moreAbstract: The molecular dynamics (MD) method was used to simulate and calculate the segregation energy and cohesive energy of Cu atoms at the Σ3{111}(110) and Σ3{112}(110) grain boundaries, and the tensile properties of the BCC-Fe crystal, with the grain boundaries containing coherent Cu clusters of different sizes (a diameter of 10 Å, 15 Å and 20 Å). The results showed that Cu atoms will spontaneously segregate towards the grain boundaries and tend to exist in the form of large-sized, low-density Cu clusters at the grain boundaries. When Cu cluster exists at the Σ3{111}(110) grain boundary, the increase in the size of the Cu cluster leads to an increase in the probability of vacancy formation inside the Cu cluster during the tensile process, weakening the breaking strength of the crystal. When the Cu cluster exists at the Σ3{112}(110) grain boundary, the Cu cluster with a diameter of 10 Å will reduce the strain hardening strength of the crystal, but the plastic deformation ability of the crystal will not be affected, and the existence of Cu clusters with a diameter of 15 Å and 20 Å will suppress the structural phase transformation of the crystal, and significantly decrease the plastic deformation ability of the crystal, thereby resulting in embrittlement of the crystal. read less USED (high confidence) J. Chen, P. Li, and E. E. Lin, “A molecular dynamics study on the mechanical properties of Fe–Ni alloy nanowires and their temperature dependence,” RSC Advances. 2020. link Times cited: 7 Abstract: Fe–Ni alloy nanowires are widely used in high-density magnet… read moreAbstract: Fe–Ni alloy nanowires are widely used in high-density magnetic memories and catalysts due to their unique magnetic and electrochemical properties. Understanding the deformation mechanism and mechanical property of Fe–Ni alloy nanowires is of great importance for the development of devices. However, the detailed deformation mechanism of the alloy nanowires at different temperatures is unclear. Herein, the deformation mechanism of Fe–Ni alloy nanowires and their mechanical properties were investigated via the molecular dynamics simulation method. It was found that the local atomic pressure fluctuation of the Fe–Ni alloy nanowire surface became more prominent with an increase in the Ni content. At low temperature conditions (<50 K), the plastic deformation mechanism of the Fe–Ni alloy nanowires switched from the twinning mechanism to the dislocation slip mechanism with the increase in the Ni content from 0.5 at% to 8.0 at%. In the temperature range of 50–800 K, the dislocation slip mechanism dominated the deformation. Simulation results indicated that there was a significant linear relationship between the Ni content, temperature, and ultimate stress in the temperature range of 50–800 K. Our research revealed the association between the deformation mechanism and temperature in Fe–Ni alloy nanowires, which may facilitate new alloy nanowire designs. read less USED (high confidence) M. Wang, G. Zhang, H. Xu, and Y. Zhang, “Atomistic Simulations and Experimental Investigations of the Diffusion Behavior of Steel/ZCuPb20Sn5 Bimetals,” THE Coatings. 2020. link Times cited: 3 Abstract: A hybrid verification method consisting of experiments and m… read moreAbstract: A hybrid verification method consisting of experiments and molecular dynamics simulations was implemented to investigate the diffusion behaviour of steel/ZCuPb20Sn5 bimetals. The effects of different carbon steels (Q235 steel, 45 steel, and T8 steel), pouring temperatures, and holding times on their microstructures and mechanical properties were studied to obtain the optimum process parameters. The experimental results indicated that the pouring temperature and holding time played an imperative role in improving the shear strength of the steel/copper bimetallic composite. The highest bonding strength of all the steel/copper bimetallic composites was obtained at 1523 K and the holding time of 40 min. Moreover, the carbon steel of 45 steel with a ZCuPb20Sn5 interface exhibited the highest bonding strength because of the appropriate pearlite content along with the preferable structure and micro-hardness for the considered diffusion width and bonding strength. Meanwhile, the diffusion distance of copper atoms in the carbon steel matrix was smaller than that of iron atoms in the ZCuPb20Sn5 matrix. In the simulation results, the diffusion coefficient of Cu atoms was smaller than that of Fe atoms, but the diffusion distance of Fe atoms in the Cu bulk was larger than that of Cu atoms in the Fe bulk; this showed a significant agreement with the experimental result. read less USED (high confidence) L.-F. Zhu, F. Körmann, A. Ruban, J. Neugebauer, and B. Grabowski, “Performance of the standard exchange-correlation functionals in predicting melting properties fully from first principles: Application to Al and magnetic Ni,” Physical Review B. 2020. link Times cited: 10 Abstract: We apply the efficient two-optimized references thermodynami… read moreAbstract: We apply the efficient two-optimized references thermodynamic integration using Langevin dynamics method [Phys. Rev. B 96, 224202 (2017)2469-995010.1103/PhysRevB.96.224202] to calculate highly accurate melting properties of Al and magnetic Ni from first principles. For Ni we carefully investigate the impact of magnetism on the liquid and solid free energies including longitudinal spin fluctuations and the reverse influence of atomic vibrations on magnetic properties. We show that magnetic fluctuations are effectively canceling out for both phases and are thus not altering the predicted melting temperature. For both elements, the generalized gradient approximation (GGA) and the local-density approximation (LDA) are used for the exchange-correlation functional revealing a reliable ab initio confidence interval capturing the respective experimental melting point, enthalpy of fusion, and entropy of fusion. read less USED (high confidence) R. Khusnutdinoff, R. Khairullina, A. Beltyukov, V. Lad’yanov, and A. Mokshin, “Viscous properties of nickel-containing binary metal melts,” Journal of Physics: Condensed Matter. 2020. link Times cited: 0 Abstract: The paper presents the results of molecular dynamics study o… read moreAbstract: The paper presents the results of molecular dynamics study of the viscosity of nickel-containing binary metal melts for a wide range of temperatures, including the region of the equilibrium liquid phase and supercooled melt. It is shown that the temperature dependencies of the viscosity of binary metal melts are described by the Kelton’s quasi-universal model. Based on the analysis of the viscosity coefficient of the binary melt composition within the framework of the Rosenfeld’s scale transformations, it has been established that to correctly describe the viscosity of binary/multicomponent metal melts within the framework of entropy models, it is necessary to use a more complex representation of the excess entropy S ex than in the approximation of pair correlation entropy S 2. read less USED (high confidence) O. Filatov and O. Soldatenko, “Influence of Glide Dislocation Motion on Self-Diffusion in b.c.c. Fe. A Molecular Dynamics Study,” Metallofizika I Noveishie Tekhnologii. 2020. link Times cited: 1 Abstract: The interaction of glide dislocations with own interstitial … read moreAbstract: The interaction of glide dislocations with own interstitial atoms in α-Fe is studied. As a method of investigation the molecular dynamics simulation is used. The modelled sample is deformed with a rate close to the deformation rates under pulsed laser treatment. Mass transfer parameter for b.c.c. Fe under laser pulse irradiation is calculated. As established, the core of moving dislocation is a trap for interstitial atom. The influence of temperature and deformation rate on mass-transfer coefficient is studied. read less USED (high confidence) A. Tsukanov et al., “Effect of Cold-Sintering Parameters on Structure, Density, and Topology of Fe–Cu Nanocomposites,” Materials. 2020. link Times cited: 8 Abstract: The design of advanced nanostructured materials with predete… read moreAbstract: The design of advanced nanostructured materials with predetermined physical properties requires knowledge of the relationship between these properties and the internal structure of the material at the nanoscale, as well as the dependence of the internal structure on the production (synthesis) parameters. This work is the first report of computer-aided analysis of high pressure consolidation (cold sintering) of bimetallic nanoparticles of two immiscible (Fe and Cu) metals using the embedded atom method (EAM). A detailed study of the effect of cold sintering parameters on the internal structure and properties of bulk Fe–Cu nanocomposites was conducted within the limitations of the numerical model. The variation of estimated density and bulk porosity as a function of Fe-to-Cu ratio and consolidation pressure was found in good agreement with the experimental data. For the first time, topological analysis using Minkowski functionals was applied to characterize the internal structure of a bimetallic nanocomposite. The dependence of topological invariants on input processing parameters was described for various components and structural phases. The model presented allows formalizing the relationship between the internal structure and properties of the studied nanocomposites. Based on the obtained topological invariants and Hadwiger’s theorem we propose a new tool for computer-aided design of bimetallic Fe–Cu nanocomposites. read less USED (high confidence) J. Sublet et al., “Neutron-induced damage simulations: Beyond defect production cross-section, displacement per atom and iron-based metrics,” The European Physical Journal Plus. 2019. link Times cited: 22 USED (high confidence) A. Tsukanov, A. Lozhkomoev, M. Lerner, I. Gotman, E. Gutmanas, and S. Psakhie, “Molecular dynamics study of bimetallic Fe–Cu Janus nanoparticles formation by electrical explosion of wires,” Philosophical Magazine. 2019. link Times cited: 3 Abstract: ABSTRACT Bimetallic nanoparticles comprised of two elements … read moreAbstract: ABSTRACT Bimetallic nanoparticles comprised of two elements which are immiscible in the bulk present a unique combination of physical–chemical properties that strongly depend on the atomic arrangement within the particle. In this study, molecular dynamics (MD) simulations of bimetallic Fe–Cu nanoparticles formation by high-velocity collision of individual metal nanoparticles (IMNPs) were performed. Physically these conditions model fast electrical explosion of two metal wires (Fe and Cu). By varying the size, temperature and velocity of colliding IMNPs, the conditions under which phase-segregated Janus nanoparticles are formed were determined. The model predictions showed good agreement with the experimental results. The present work is a step forward to understanding the formation mechanisms of bimetallic nanoparticles with different chemical configurations. read less USED (high confidence) M. R. Karim, M. Kattoura, S. Mannava, V. Vasudevan, A. Malik, and D. Qian, “A computational study on the microstructural evolution in near-surface copper grain boundary structures due to femtosecond laser processing,” Computational Mechanics. 2018. link Times cited: 6 USED (high confidence) M. R. Karim, M. Kattoura, S. Mannava, V. Vasudevan, A. Malik, and D. Qian, “A computational study on the microstructural evolution in near-surface copper grain boundary structures due to femtosecond laser processing,” Computational Mechanics. 2017. link Times cited: 0 USED (high confidence) J. Zhou et al., “Zener pinning by coherent particles: pinning efficiency and particle reorientation mechanisms,” Modelling and Simulation in Materials Science and Engineering. 2017. link Times cited: 13 Abstract: Zener pinning by coherent particles in copper–nickel model a… read moreAbstract: Zener pinning by coherent particles in copper–nickel model alloys has been studied using molecular dynamics simulations. It is found that 4 nm Ni particles were easily cut by migrating Cu grain boundaries during boundary passage, while 7–8 nm particles were harder to cut and coherency-to-incoherency change occurred for some boundaries. Due to low volume fraction and easy cutting, 4 nm particles had a limited pinning effect on grain boundary motion. The increase in volume fraction and the suppressed cutting for 7–8 nm particles caused the boundary motion to be significantly retarded. Different grain boundaries exhibited the distinct ability to move past the same size particle. Significantly, with the pinning effect of Ni particles, misorientation dependence of boundary migration velocity became obvious, which is consistent with the findings in practical materials. During or after passage, the Ni particles were found to change orientation to become coherent with grain growth via various atomistic mechanisms. The mechanisms were discussed with respect to particle size and boundary misorientation. read less USED (high confidence) I. N. Kar’kin, L. E. Kar’kina, P. Korzhavyi, and Y. Gornostyrev, “Monte Carlo simulation of the kinetics of decomposition and the formation of precipitates at grain boundaries of the general type in dilute BCC Fe–Cu alloys,” Physics of the Solid State. 2017. link Times cited: 8 USED (high confidence) W. Cui et al., “Up-Hill Diffusion of Phase-Separated FeCu Melt by Molecular Dynamics Simulation,” Chinese Physics Letters. 2017. link Times cited: 2 USED (high confidence) W. Tucker and P. Schelling, “Thermodiffusion in liquid binary alloys computed from molecular-dynamics simulation and the Green-Kubo formalism,” Computational Materials Science. 2016. link Times cited: 8 USED (high confidence) C. Race, “Quantifying uncertainty in molecular dynamics simulations of grain boundary migration,” Molecular Simulation. 2015. link Times cited: 17 Abstract: Molecular dynamics simulations of simple bicrystal systems h… read moreAbstract: Molecular dynamics simulations of simple bicrystal systems have been much used as a tool to explore how the migration of grain boundaries varies with their structure and with experimental conditions. In order to permit the exploration of a large parameter space, many studies are forced to rely on a small number of simulations (often a single simulation) for each configuration. The motion of a grain boundary is inherently statistical and any variability in the measured grain boundary velocity should be taken into account in subsequent analysis of trends in grain boundary mobility. Here we present the results of large numbers of simulations of equivalent boundaries, which show that this variability can be large, particularly when small systems are simulated. We show how a bootstrap resampling approach can be used to characterise the statistical uncertainty in boundary velocity using the information present in a single simulation. We show that the approach is robust across a variety of system sizes, temperatures and driving force strengths and types, and provides a good order-of-magnitude measure of the population standard deviation across multiple equivalent simulations. read less USED (high confidence) D. Molnár, U. Weber, P. Binkele, D. Rapp, and S. Schmauder, “Prediction of macroscopic damage behaviour of precipitation strengthened steels via multiscale simulations,” GAMM‐Mitteilungen. 2015. link Times cited: 6 Abstract: A multiscale modelling approach is presented that sequential… read moreAbstract: A multiscale modelling approach is presented that sequentially connects in total five simulation methods via parameter transfers in order to capture the macroscopic damage behaviour due to an underlying nano structure of copper precipitates in bcc iron. In this multiscale approach, information on precipitation states is taken from kinetic Monte‐Carlo and Phasefield simulations as well as from experimental data. Based on a calibration of Dislocation Dynamics by Molecular Dynamics simulations as well as on testing conditions known from experiments, Dislocation Dynamics simulations with an infinite dislocation on a single glide plane provide strengthening levels which are related to a reference stress‐strain curve obtained from experiments. Subsequently, the macroscopic damage behaviour is simulated with the Finite‐Element‐Method including the Rousselier Damage Model for the reference state as well as for the virtually aged states. The results are validated by comparison with experimental results and predictions are made with respect to specific precipitation cases. (© 2015 WILEY‐VCH Verlag GmbH & Co. KGaA, Weinheim) read less USED (high confidence) G. Lv, H. Zhang, X. He, W. Yang, and Y. Su, “Atomistic simulation of Cu–Ni precipitates hardening in α-iron,” Journal of Physics D: Applied Physics. 2015. link Times cited: 7 Abstract: In this paper, we investigated the interaction of an edge di… read moreAbstract: In this paper, we investigated the interaction of an edge dislocation with Cu precipitates with a spherical geometry and with Cu–Ni precipitates that possess a Cu core with an outer Ni shell, commonly observed in reactor pressure vessel (RPV) steels. We applied molecular dynamics techniques to explore the critical stress required to unpin the dislocation (CSRUD), the breakaway dislocation line shape when the dislocation leaves the precipitates and the transition of Cu atoms within precipitates. The results indicate that the CSRUD of the Cu–Ni precipitates with a diameter less than 2.38 nm is larger than that of Cu precipitates that contain the same number of Cu atoms, while for a diameter larger than 2.38 nm, the CSRUD of Cu–Ni precipitates is weaker, which is related to the bcc to fcc-like or hcp-like atoms transformation in precipitates. The dislocations interact with Cu and Cu–Ni precipitates via the cut mechanism. read less USED (high confidence) L. Shao et al., “Sink property of metallic glass free surfaces,” Scientific Reports. 2015. link Times cited: 18 USED (high confidence) S. Vigonski, F. Djurabekova, M. Veske, A. Aabloo, and V. Zadin, “Molecular dynamics simulations of near-surface Fe precipitates in Cu under high electric fields,” Modelling and Simulation in Materials Science and Engineering. 2015. link Times cited: 14 Abstract: High electric fields in particle accelerators cause vacuum b… read moreAbstract: High electric fields in particle accelerators cause vacuum breakdowns in the accelerating structures. The breakdowns are thought to be initiated by the modification of material surface geometry under high electric fields. These modifications in the shape of surface protrusions enhance the electric field locally due to the increased surface curvature. Using molecular dynamics, we simulate the behaviour of Cu containing a near-surface Fe precipitate under a high electric field. We find that the presence of a precipitate under the surface can cause the nucleation of dislocations in the material, leading to the appearance of atomic steps on the surface. Steps resulting from several precipitates in close proximity can also form protruding plateaus. Under very high external fields, in some cases, we observed the formation of voids above or below the precipitate, providing additional dislocation nucleation sites. read less USED (high confidence) S. Shao, J. Wang, and A. Misra, “Energy minimization mechanisms of semi-coherent interfaces,” Journal of Applied Physics. 2014. link Times cited: 51 Abstract: In this article, we discussed energy minimization mechanisms… read moreAbstract: In this article, we discussed energy minimization mechanisms of semi-coherent interfaces based on atomistic simulations and dislocation theory. For example, of {111} interfaces between two face centered cubic (FCC) crystals, interface comprises of two stable structures (normal FCC stacking structure and intrinsic stacking fault structure), misfit dislocations, and misfit dislocation intersections or nodes (corresponding to the high energy stacking fault (HESF) structure). According to atomistic simulations of four interfaces, we found that (1) greater spacing between misfit dislocations and/or larger slopes of generalized stacking fault energy at the stable interface structures leads to a narrower dislocation core and a higher state of coherency in the stable interfaces; (2) the HESF region is relaxed by the relative rotation and dilation/compression of the two crystals at the node. The crystal rotation is responsible for the spiral feature at the vicinity of a node and the dilation/compression is responsible for the creation of the free volume at a node; (3) the spiral feature is gradually frail and the free volume decreases with decreasing misfit dislocation spacing, which corresponds to an increase in lattice mismatch and/or a decrease in lattice rotation. Finally, the analysis method and energy minimization mechanisms explored in FCC {111} semi-coherent interfaces are also applicable for other semi-coherent interfaces. read less USED (high confidence) Y. Satoh, H. Abe, and T. Matsunaga, “Radiation-induced glide motion of interstitial clusters in concentrated alloys,” Philosophical Magazine. 2014. link Times cited: 4 Abstract: We propose a mechanism for glide motion, i.e. one-dimensiona… read moreAbstract: We propose a mechanism for glide motion, i.e. one-dimensional (1D) migration, of interstitial clusters in concentrated alloys driven by high-energy particle irradiation. Interstitial clusters are fundamentally mobile on their respective 1D migration tracks, but in concentrated random alloys they are stationary at the position where the fluctuating formation energy achieves a local minimum. Irradiation changes the microscopic distribution of solute atoms through atomic displacement and recovery of the produced Frenkel pairs, which causes cluster 1D migration into a new stable position. In molecular dynamics simulations of interstitial clusters up to 217i in Fe–Cu alloys, stepwise 1D migration was observed under interatomic mixing or shrinkage of the cluster: a single 1D migration was induced by two exchanges per atom or cluster radius change by two interatomic distances. The 1D migration distance ranged up to several nanometers. We compared the frequency and distance of 1D migration with those for in situ observation using high-voltage electron microscopy, allowing for the extremely large rate of interatomic mixing and cluster shrinkage in the present simulation. read less USED (high confidence) T. Rupert, “Solid Solution Strengthening and Softening Due to Collective Nanocrystalline Deformation Physics,” arXiv: Materials Science. 2014. link Times cited: 34 USED (high confidence) S. Shao, J. Wang, A. Misra, and R. Hoagland, “Spiral Patterns of Dislocations at Nodes in (111) Semi-coherent FCC Interfaces,” Scientific Reports. 2013. link Times cited: 91 USED (high confidence) D. Molnár, P. Binkele, S. Hocker, and S. Schmauder, “Atomistic multiscale simulations on the anisotropic tensile behaviour of copper-alloyed alpha-iron at different states of thermal ageing,” Philosophical Magazine. 2012. link Times cited: 18 Abstract: The mechanical behaviour of steels is strongly related to th… read moreAbstract: The mechanical behaviour of steels is strongly related to their underlying atomistic structures which evolve during thermal treatment. Cu-alloyed α-Fe undergoes a change in material behaviour during the ageing process, especially at temperatures of above 300°C, where precipitates form on a large time-scale within the α-Fe matrix, yielding first a precipitation strengthening of the material. As the precipitates grow further in time, the material strength decreases again. This complex process is modelled with a multiscale approach, combining Kinetic Monte Carlo (KMC) with Molecular Dynamics (MD) simulations in a sequential way and exploiting the advantages of both methods while simultaneously circumventing their particular disadvantages. The formation of precipitates is modelled on a single-crystal lattice with a diffusion based KMC approach. Transferring selected precipitation states at different ageing times to MD simulations allows the performance of nano tensile tests and the analysis of failure initiation. The anisotropic tensile behaviour is investigated in the [100], [110] and [111] directions, showing monotonically decreasing tensile strengths and deformation strains. Hence precipitation strengthening is mainly due to dislocation–precipitate interactions which are non-existent at small tensile loadings in this scenario. At the point of ductile failure, dislocations are generated at the interfaces between precipitates and the Fe matrix. Straining in the [100] direction, they lie on {110} and {112} glide planes, as expected. With the method presented here, the changes of the anisotropic tensile moduli are related to different states of thermal ageing, i.e., to nucleation, growth and Ostwald ripening of Cu precipitates. read less USED (low confidence) S. Kumar, A. Rajput, S. K. Paul, M. Tiwari, and D. K. Prajapati, “Friction and wear study of metallic contacts under dry sliding conditions: A molecular dynamics simulation-based approach,” Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology. 2023. link Times cited: 0 Abstract: Sliding friction originating due to ploughing and adhesive w… read moreAbstract: Sliding friction originating due to ploughing and adhesive wear significantly affects the performance of small-scale components, that is, nano-electromechanical systems/micro-electromechanical. To get a comprehensive understanding of the friction mechanisms, a comprehensive study of surface interactions at the nanoscale is crucial, particularly when dealing with nano-electromechanical and micro-electromechanical components. This study performed molecular dynamics simulation to explore the interactions between asperities (made of similar/dissimilar materials) at the nanoscale under dry sliding conditions. The research framework focuses on modelling the contact between two hemispherical asperities during dry sliding by considering three material combinations: soft-to-soft (Cu–Cu), hard-to-hard (Fe–Fe), and hard-to-soft (Fe–Cu). The study assesses plastic deformation and atomic wear at specific sliding speeds. Notably, the results indicate that the frictional force on the lower asperity increases as interference increases. Additionally, atomic wear rises with increased interference in the case of the Fe–Cu tribopair. Particularly high atomic wear is observed in the Cu–Cu tribopair due to the ease of slip within the face-centred cubic crystal structure of copper. read less USED (low confidence) Y. He, Z. Gao, M. Tang, X. Sun, P. Gao, and J. Sun, “Characteristics of atomic removal and mechanism of damage formation in vibration-assisted nano cutting of copper-nickel alloy,” Materials Today Communications. 2023. link Times cited: 0 USED (low confidence) X. Zhu, X. Wang, Y. Liu, Y. Luo, and H. Zhang, “Probing the Effect of Cuttings Particle Size on the Friction and Wear Mechanism at the Casing Friction Interface: A Molecular Dynamics Study.,” Langmuir : the ACS journal of surfaces and colloids. 2023. link Times cited: 0 Abstract: Cuttings particles of different sizes in the drilling fluid … read moreAbstract: Cuttings particles of different sizes in the drilling fluid are the leading cause of wear at the casing and drill pipe joints, and diamond-like carbon (DLC) films have excellent research potential in reducing tool wear due to their ultra-low friction coefficient and high wear resistance. In this paper, a corresponding molecular dynamics model was developed using LAMMPS to investigate the effect of silica particles of different particle sizes on the friction and wear mechanisms of Fe/DLC friction pairs at the microscale. The results show that small cuttings particles in a dry environment are more likely to cause interface wear between the casing and drill pipe joint, while in a water environment, the opposite is true. The main reason is that small particles in a dry environment have smaller contact areas and greater indentation depth, leading to greater wear at the friction interface. The movement of water molecules in the water environment will promote the composite movement of large particles, thereby exacerbating the wear of the interface. Moreover, the relevant research results at the micro-scale indicate that DLC films can effectively reduce wear, which provides theoretical support for its application in drill pipe joints. read less USED (low confidence) A. Kumar, R. Kumar, S. Kumar, and A. K. V, “Atomistic structural transformation of Fe-Cr-Ni single crystal alloy under uniaxial deformation using molecular dynamics simulation,” Materials Today: Proceedings. 2023. link Times cited: 0 USED (low confidence) D. Tramontina et al., “Probing radiation resistance in simulated metallic core–shell nanoparticles,” Computational Materials Science. 2023. link Times cited: 0 USED (low confidence) T. Zhou, Y. Wu, and J.-J. You, “Evolution of the shape and microstructure of body-centered cubic seeds during Cu melt solidification,” Chemical Physics Letters. 2023. link Times cited: 0 USED (low confidence) N. Wang et al., “An experimental and molecular dynamics study on the formation of low-energy grain boundaries induced by grain rotation during rapid solidification,” Materials Letters. 2023. link Times cited: 0 USED (low confidence) W. Pang, X.-jing Feng, R. Chen, A. Liu, and K. Xin, “Molecular dynamics studies of the effect of intermediate Fe layer thickness on the enhanced strength and ductility of Cu/Fe/Ni multilayer,” Physica Scripta. 2023. link Times cited: 0 Abstract: The synergistic strength-ductility is very important for com… read moreAbstract: The synergistic strength-ductility is very important for composite materials. In this work, we studied the effect of intermediate layer thickness on the mechanical properties of Cu/Fe/Ni multilayer by introducing harder intermediate layer and non-coherent interface using molecular dynamics simulation, and revealed the relationship between the deformation mechanism and the strength-ductility from atomic scale. The results show that the yield strength and flow stress increase with increasing Fe layer thickness, but the tensile strain is opposite. Plastic deformation of all models are triggered by slipping of misfit partial dislocation originating from the decomposition of perfect dislocation on semi-coherent interface. However, the addition of Fe layer and non-coherent interface increases the resistance of dislocation crossing interface, and changes the dominant deformation mechanism from Shockley partial dislocation slipping to deformation twinning migration, thus improving the strength and ductility of multilayer. In addition, the evolution laws of the dislocation length and interface morphology as well as the shear strain distribution are discussed. read less USED (low confidence) R. Barik, S. Biswal, A. Dutta, D. Chakrabarti, and A. Ghosh, “Effect of solute distribution on the screw dislocation motion in bcc Fe-based systems,” Computational Materials Science. 2023. link Times cited: 0 USED (low confidence) A. Dmitriev and A. Nikonov, “Molecular-Dynamic Study of the Interfacial Zone of Dissimilar Metals Under Compression and Shear,” Russian Physics Journal. 2023. link Times cited: 0 USED (low confidence) S. Yang, H. Bao, H. Bai, Y. Li, H. Xu, and F. Ma, “Effects of Fe solid solute on grain boundaries of bi-crystal Cu: A molecular dynamics simulation,” Nano Materials Science. 2023. link Times cited: 0 USED (low confidence) F. Wang et al., “Enhanced nanocrystalline stability of BCC iron via copper segregation,” Progress in Natural Science: Materials International. 2023. link Times cited: 4 USED (low confidence) “A physically-based constitutive model for a novel heat resistant martensitic steel under different cyclic loading modes: Microstructural strengthening mechanisms,” International Journal of Plasticity. 2023. link Times cited: 12 USED (low confidence) B. Li, R. Ma, S. Qin, and X. Zhang, “Regulating the dislocation-nanocluster interactions by electrical pulses to alleviate material hardening,” Materials Science and Engineering: A. 2023. link Times cited: 0 USED (low confidence) K. Bandyopadhyay, S. Das, K. S. Ghosh, and M. Ghosh, “Molecular Dynamics-Based Scheme of Designing Nanostructured Cu-Ni Alloy Thin Film for Coating on Advanced Structural Components in Naval Vessels,” Journal of Materials Engineering and Performance. 2022. link Times cited: 2 USED (low confidence) Y. Lei et al., “An Embedded-Atom Method Potential for studying the properties of Fe-Pb solid-liquid interface,” Journal of Nuclear Materials. 2022. link Times cited: 1 USED (low confidence) G. Zhang, M. Wang, H. Yu, H. Xu, and A. Wan, “Molecular Dynamics and Experimental Investigation on the Interfacial Binding Mechanism in the Fe/Cu1−x-Nix Bimetallic Interface,” Nanomaterials. 2022. link Times cited: 0 Abstract: To systematically investigate the diffusion behavior of Fe/C… read moreAbstract: To systematically investigate the diffusion behavior of Fe/Cu bimetallic materials and the influence of the Ni element on the diffusion and mechanical properties of the Fe/Cu bimetallic interface, the diffusion distance, diffusion coefficient, and strain–stress process based on molecular dynamics (MD) calculations and experimental testing were analyzed. All simulation results indicated that the liquid Cu matrix had a higher diffusion coefficient but hardly diffused into the Fe matrix, and the solid Fe matrix had a smaller diffusion coefficient but diffused deep into the Cu matrix at the same temperature. Compared with the initial state, the addition of nickel atoms to the Cu matrix favored the improvement of the diffusion coefficient and the diffusion distance of Fe/Cu bimetallic materials. Moreover, we found that the diffusion distance and the yield strength simultaneously increased and then decreased with the increase in Ni atoms, which is in agreement with the experimental test results. These improvements in the diffusion and mechanical properties were attributed to the enrichment of Ni atoms at the interface, but excessive Ni content resulted in deteriorated properties. Finally, our research described the enhancement mechanism of the addition of nickel atoms to the Fe/Cu bimetallic diffusion system. An analysis of the contributions of the diffusion distance, the diffusion coefficient, and the yield strength revealed that the diffusion properties of nickel atoms play an important role in Fe/Cu bimetallic materials. read less USED (low confidence) K. Ren, L. Liu, J. Li, H. Pan, and Z. Wang, “Lubrication Behavior of n-hexadecane on ZnO Layer at the Nanoscale: A Molecular Dynamic Exploration,” Tribology Letters. 2022. link Times cited: 1 USED (low confidence) G. Dai, S. Wu, X. Huang, M.-jie Wang, and X. Teng, “Thermal diffusion behavior of Fe/Cu/Ni multilayer coatings: a molecular dynamics study,” Modelling and Simulation in Materials Science and Engineering. 2022. link Times cited: 1 Abstract: In this paper, the thermal diffusion behavior of Fe/Cu/Ni mu… read moreAbstract: In this paper, the thermal diffusion behavior of Fe/Cu/Ni multilayer coatings was investigated by molecular dynamics. The results show that the Fe, Cu, and Ni elements can diffuse each other at 1250 K. Meanwhile, the intrinsic diffusion coefficients and interdiffusion coefficients of the Fe, Cu, and Ni were calculated. Besides, the diffusion mechanism for high melting-point elements of Fe and Ni at 1250 K was analyzed in the paper. According to the simulation result, the Fe and Ni lattices were disturbed by the active Cu particles. Fe and Ni particles at higher energies may move out of their original positions and migrate into the Cu lattice randomly. Thus, the Fe and Ni elements were involved in the thermal diffusion. This can be confirmed by the decrease of the peak and the disappearance of the secondary peak in the radial distribution function curves. However, the position of the curve peaks did not change. Thus, the lattice structure was still maintained during the whole diffusion process. The thermal diffusion of the three elements was carried out by particle substitution at the lattice positions. It was a solid phase diffusion process. Furthermore, there was a clear particle diffusion asymmetry at the original interface of the element. It was consistent with the diffusion asymmetry of diffusion-couple experiments. The primary reason for this diffusion asymmetry was the difference in the interaction potential of the three elements. This asymmetry was ultimately reflected in the intrinsic diffusion coefficient and the interdiffusion coefficient of each element. For the Fe–Cu–Ni ternary system, the largest diffusion coefficient was copper and the smallest was iron at 1250 K. read less USED (low confidence) Y. Deng et al., “Molecular dynamics simulation of the growth and diffusion mechanisms of Fe–Cu bimetallic nanoparticles,” Philosophical Magazine. 2022. link Times cited: 1 Abstract: ABSTRACT In accordance with the molecular dynamic simulation… read moreAbstract: ABSTRACT In accordance with the molecular dynamic simulation and nudged elastic band method, the surface diffusion and growth of Fe–Cu nanoparticles were studied, respectively, using Large-scale Atomic/Molecular Massively Parallel Simulator code. Results showed that a single Cu adatom diffused on the surface of the Fe substrate mainly via the hopping mechanism and nearly did not exchange with the substrate atoms. In the Cu substrate, when interfacet diffusion of a Fe adatom on the surface was activated, the system energy evidently decreased after the exchange mechanism was chosen. At low temperatures, the metastable core–shell structure of FeshellCucore nanoparticles was obtained by simulating the deposition of Fe on Cu substrate. For the growth of Cu on Fe substrate, FecoreCushell nanoparticles could be formed and they gradually evolved into Wulff-like structures with depositing Cu atoms. The Monte Carlo calculation further showed that the stable configuration of Fe–Cu nanoparticles is FecoreCushell when the concentration of Cu atoms is small. With the increase of Cu atomic ratio (enough to cover the surface), the quasi-Janus was the stable structure in Fe–Cu nanoparticles. read less USED (low confidence) D. Yang, H. Liu, Q. Jiang, Y. Jiang, X. Wang, and W. Yang, “Atomic-level understanding of weakening crystallization in additive manufactured ternary Fe-based metallic glasses with Ni addition,” Journal of Non-Crystalline Solids. 2022. link Times cited: 5 USED (low confidence) H. Bao, H. Xu, Y. Li, H. Bai, and F. Ma, “The interaction mechanisms between dislocations and nano-precipitates in CuFe alloys: a molecular dynamic simulation,” International Journal of Plasticity. 2022. link Times cited: 11 USED (low confidence) J. Syarif, V. Gillette, H. Hussien, K. Badawy, and N. Jisrawi, “Molecular dynamics simulation of the amorphization and alloying of a mechanically milled Fe-Cu system,” Journal of Non-Crystalline Solids. 2022. link Times cited: 1 USED (low confidence) I. Camacho et al., “On the anticorrosion mechanism of molten salts based nanofluids,” Solar Energy Materials and Solar Cells. 2022. link Times cited: 5 USED (low confidence) Z. Shi, B. Li, and Z. Sun, “Study on microstructure evolution of grinding surface of bcc Fe-Ni maraging steel based on molecular dynamics,” Applied Surface Science. 2022. link Times cited: 7 USED (low confidence) A. Mishra, J. Lind, M. Kumar, and A. Dongare, “Understanding the phase transformation mechanisms that affect the dynamic response of Fe-based microstructures at the atomic scales,” Journal of Applied Physics. 2021. link Times cited: 8 USED (low confidence) J. Yin, H. Hou, J. Wang, X. Liu, and F. Xue, “Atomistic simulation of [100](001) crack propagation with Cu precipitates in α-iron,” International Journal of Pressure Vessels and Piping. 2021. link Times cited: 4 USED (low confidence) C. Yi, C. Hu, L. Shi, M.-li Bai, and J. Lv, “Wettability of complex Long-Chain alkanes droplets on Pillar-type surfaces,” Applied Surface Science. 2021. link Times cited: 4 USED (low confidence) D. S. Sineglazov, S. Divinski, and A. V. Pokoev, “Simulation of the Magnetoplastic Effect in a Cu–Ni Alloy,” Journal of Surface Investigation: X-ray, Synchrotron and Neutron Techniques. 2021. link Times cited: 0 USED (low confidence) X.-jing Feng, Z. Lin, K. Xin, and W. Pang, “The deformation mechanisms and mechanical properties of Cu/Fe multilayer during compression process,” Journal of Materials Research. 2021. link Times cited: 4 Abstract: The deformation mechanisms and mechanical properties of Cu/F… read moreAbstract: The deformation mechanisms and mechanical properties of Cu/Fe multilayer during compression process are investigated via atomistic simulations and rationalized analysis. It is found that yield stress and strain of Kurdjumov–Sachs model are lower than that of Nishiyama–Wassermann model, and lattice dislocation nucleates from periodic arrangement structures on the interface. We present that preferred slip systems are dominated not only by Schmidt factors but also by intersection line orientations of slip system on the interface, as well as angles between activated slip system of Cu layer and slip system of Fe layer. During deformation process, extended full dislocation dominates deformation behavior of Cu layer, and perfect dislocation and twinning dominate deformation behavior of Fe layer. After deformation, tetrahedral structures and point defects form on Cu side of interface and inside Fe layer, respectively. We calculate evolution curves for number of dislocation segments and interface thickness to illuminate deformation behavior. read less USED (low confidence) X. Li, Z.-an Tian, Q. Xie, and K. Dong, “The topologically close-packed Fe70Cu15Ni15 nanoparticles- A simulation study,” Vacuum. 2021. link Times cited: 3 USED (low confidence) X.-Y. Liu, L. Capolungo, and A. Hunter, “Screw dislocation impingement and slip transfer at fcc-bcc semicoherent interfaces,” Scripta Materialia. 2021. link Times cited: 9 USED (low confidence) H. Xu, H. Bao, Y. Li, H. Bai, and F. Ma, “Atomic scale insights into the rapid crystallization and precipitation behaviors in FeCu binary alloys,” Journal of Alloys and Compounds. 2021. link Times cited: 5 USED (low confidence) Y. Li et al., “Shear-strain induced structural relaxation of Cu Σ3 [110](112) symmetric tilt grain boundary: The role of foreign atoms and temperature,” Current Applied Physics. 2021. link Times cited: 1 USED (low confidence) N. Eom, M. Messing, J. Johansson, and K. Deppert, “General Trends in Core–Shell Preferences for Bimetallic Nanoparticles,” ACS Nano. 2021. link Times cited: 36 Abstract: Surface segregation phenomena dictate core–shell preference … read moreAbstract: Surface segregation phenomena dictate core–shell preference of bimetallic nanoparticles and thus play a crucial role in the nanoparticle synthesis and applications. Although it is generally agreed that surface segregation depends on the constituent materials’ physical properties, a comprehensive picture of the phenomena on the nanoscale is not yet complete. Here we use a combination of molecular dynamics (MD) and Monte Carlo (MC) simulations on 45 bimetallic combinations to determine the general trend on the core–shell preference and the effects of size and composition. From the extensive studies over sizes and compositions, we find that the surface segregation and degree of the core–shell tendency of the bimetallic combinations depend on the sufficiency or scarcity of the surface-preferring material. Principal component analysis (PCA) and linear discriminant analysis (LDA) on the molecular dynamics simulations results reveal that cohesive energy and Wigner–Seitz radius are the two primary factors that have an “additive” effect on the segregation level and core–shell preference in the bimetallic nanoparticles studied. When the element with the higher cohesive energy also has the larger Wigner–Seitz radius, its core preference decreases, and thus this combination forms less segregated structures than what one would expect from the cohesive energy difference alone. Highly segregated structures (highly segregated core–shell or Janus-like) are expected to form when both the relative cohesive energy difference is greater than ∼20%, and the relative Wigner–Seitz radius difference is greater than ∼4%. Practical guides for predicting core–shell preference and degree of segregation level are presented. read less USED (low confidence) J. Syarif and K. Badawy, “Computational modelling of cold rolling of ferritic iron containing ε-Cu precipitates,” Materials today communications. 2021. link Times cited: 0 USED (low confidence) F. Tan, F. Li, Q. Fang, J. Li, and H. Feng, “Grain boundary migration and deformation mechanism influenced by heterogeneous precipitate,” Journal of Materials Science. 2021. link Times cited: 2 USED (low confidence) S. Eder, P. Grützmacher, M. R. Ripoll, and J. Belak, “Elucidating the Onset of Plasticity in Sliding Contacts Using Differential EBSD Tomography.” 2021. link Times cited: 0 Abstract:

Depending on the mechanical and thermal energy introduced … read moreAbstract: